Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Die Repair Machinist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

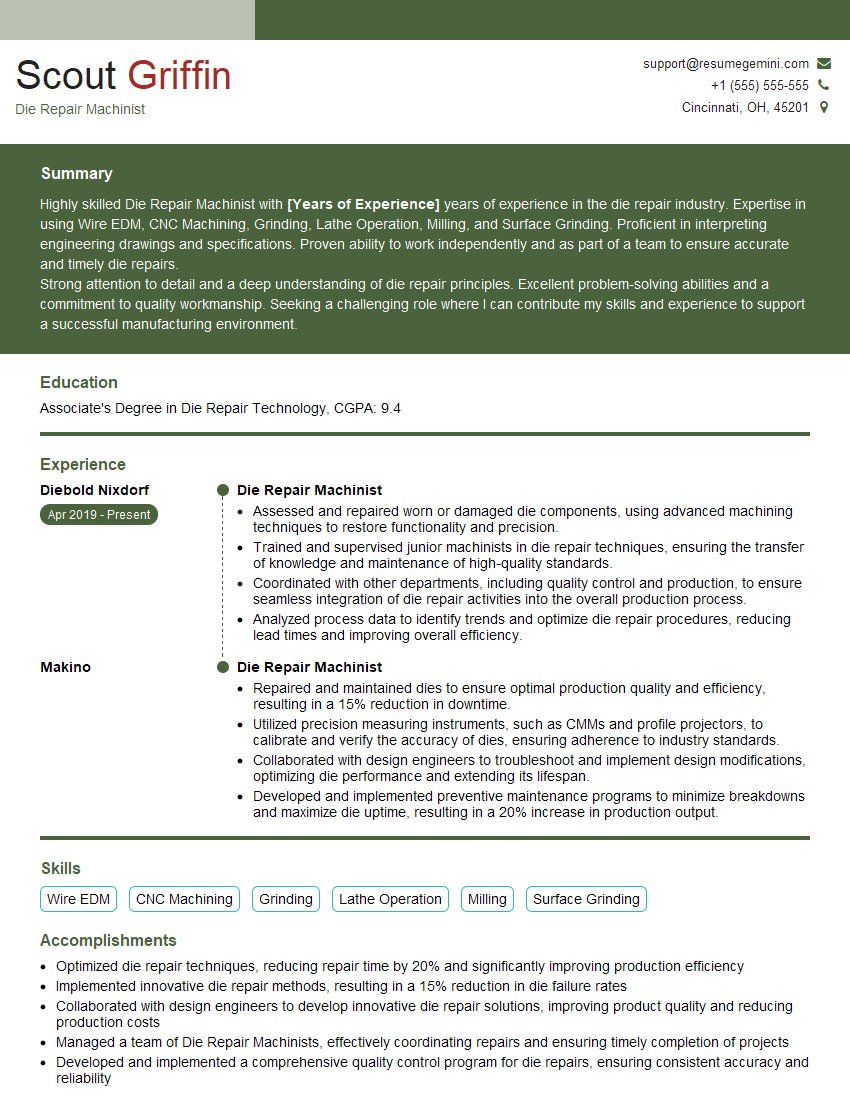

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Repair Machinist

1. How do you inspect the die for any damage or wear, and what tools or techniques do you use?

- Visual inspection: Look for any cracks, chips, or other damage on the die’s surface.

- Dimensional inspection: Use calipers, micrometers, or other measuring tools to check the die’s dimensions against the design specifications.

- Hardness testing: Use a Rockwell or Vickers hardness tester to check the die’s hardness and ensure it meets the required specifications.

2. How do you determine the root cause of die failure, and what steps do you take to prevent it from recurring?

- Analyze the failed die to identify the type of failure and its potential causes.

- Review the die’s design, materials, and manufacturing process to identify any potential weaknesses or areas for improvement.

- Implement corrective actions to address the root cause of failure and prevent it from recurring in future dies.

3. Describe the different types of die repair techniques you are familiar with and when each technique is best applied.

- Welding: Used to repair cracks, chips, or other damage on the die’s surface.

- EDM (Electrical Discharge Machining): Used to remove material from the die’s surface or to create intricate shapes.

- Laser welding: Used to repair fine cracks or to weld small parts onto the die.

4. What are the key safety considerations you take when performing die repair operations?

- Wear appropriate safety gear, including gloves, eye protection, and a face mask.

- Ensure the work area is well-ventilated and free of hazardous fumes.

- Use proper lifting techniques when handling heavy dies.

5. How do you ensure the repaired die meets the original design specifications and performs to the required standards?

- Re-inspect the repaired die to ensure it meets the original dimensions and tolerances.

- Perform functional testing to verify that the repaired die operates properly.

- Obtain approval from the engineering or quality control department before releasing the repaired die for production.

6. How do you stay up-to-date with the latest advancements in die repair techniques and technologies?

- Attend industry conferences and seminars.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

7. What is your experience in working with different die materials, such as steel, carbide, and ceramic?

- Describe your experience with welding, grinding, and other machining operations on various die materials.

- Explain how you select the appropriate repair technique based on the die material and the type of damage.

8. How do you handle situations where a die repair is particularly challenging or requires a custom solution?

- Describe your problem-solving approach and how you work with engineers or other specialists to develop innovative repair solutions.

- Provide examples of challenging repairs that you have successfully completed.

9. What are the quality standards that you follow when performing die repairs, and how do you ensure that the repaired dies meet these standards?

- Explain your understanding of industry quality standards and how you implement them in your work.

- Describe the inspection and testing procedures that you follow to verify the quality of repaired dies.

10. How do you prioritize your workload and manage your time effectively when there are multiple die repairs to be completed?

- Describe your approach to prioritizing repairs based on urgency and criticality.

- Explain how you manage your time to complete repairs efficiently and meet deadlines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Repair Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Repair Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Die Repair Machinist is responsible for a wide array of duties in the manufacturing industry, primarily focusing on repairing and maintaining dies used in stamping, punching, and other metalworking processes. They possess highly specialized skills in machining, troubleshooting, and precision measurement to ensure optimal performance and longevity of dies.

1. Die Repair and Maintenance

The primary responsibility of a Die Repair Machinist is to repair and maintain dies to ensure their proper functionality and prevent breakdowns. This involves:

- Inspecting dies regularly to identify wear and tear, cracks, or other defects

- Disassembling and cleaning dies to prepare them for repairs

- Repairing or replacing damaged components, such as guide pins, stripper plates, and cutting edges

- Performing precision grinding, milling, and other machining operations to restore die dimensions and tolerances

2. Troubleshooting and Problem Solving

Die Repair Machinists play a crucial role in troubleshooting and resolving issues related to dies. They analyze problems, identify root causes, and develop effective solutions to minimize downtime and maintain production efficiency.

- Analyzing die failures to determine the cause and implement corrective measures

- Troubleshooting electrical, hydraulic, and mechanical problems in dies

- Identifying and rectifying issues that affect the quality and accuracy of stamped parts

- Collaborating with engineers and other technicians to resolve complex problems

3. Precision Measurement and Inspection

Die Repair Machinists use precision measuring instruments and techniques to ensure the accuracy and tolerances of repaired dies. They meticulously check dimensions, clearances, and surface finishes to meet specifications.

- Using micrometers, calipers, and coordinate measuring machines (CMMs) to measure die components

- Checking the alignment and parallelism of dies to ensure proper stamping operations

- Conducting dimensional inspections to verify the conformance of repaired dies to original specifications

- Preparing inspection reports and maintaining records of measurements and repairs

4. Preventive Maintenance and Documentation

To prevent breakdowns and extend the lifespan of dies, Die Repair Machinists perform regular preventive maintenance tasks and document all repairs and modifications. This involves:

- Lubricating and cleaning dies to minimize wear and corrosion

- Replacing worn or damaged components before they cause failures

- Keeping detailed records of all repairs, modifications, and inspections performed on dies

- Providing recommendations on die maintenance and handling practices to improve equipment longevity

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some key tips to help you ace your interview for a Die Repair Machinist position:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. Learn about the company’s history, products, and industry reputation. Understand the responsibilities and expectations of the Die Repair Machinist role. This knowledge will help you demonstrate your interest and understanding of the company and the position.

2. Highlight Your Skills and Experience

In your interview, be sure to emphasize your skills and experience that are relevant to the Die Repair Machinist role. Highlight your expertise in die repair, troubleshooting, precision measurement, and preventive maintenance. Provide specific examples of projects or assignments where you successfully repaired or maintained dies. Quantify your results whenever possible to demonstrate your impact.

3. Practice Your Answers

Practice answering common interview questions related to die repair and maintenance. Consider questions about your technical skills, problem-solving abilities, and attention to detail. Prepare clear and concise answers that showcase your strengths and qualifications. Practicing your answers will help you feel more confident and articulate during the interview.

4. Ask Insightful Questions

At the end of the interview, be prepared to ask insightful questions that demonstrate your interest in the position and the company. This is an opportunity to clarify any details about the role, the company culture, or the industry trends. Asking thoughtful questions shows that you are engaged and eager to learn more.

5. Follow Up After the Interview

After the interview, send a thank-you note to the interviewer within 24 hours. This is a professional courtesy that shows your appreciation for their time and consideration. In your thank-you note, reiterate your interest in the position, highlight a key skill or experience you discussed, and express your enthusiasm for the opportunity. Following up after the interview leaves a positive impression and may increase your chances of being considered for the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Repair Machinist interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.