Feeling lost in a sea of interview questions? Landed that dream interview for Die Set Up Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Die Set Up Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

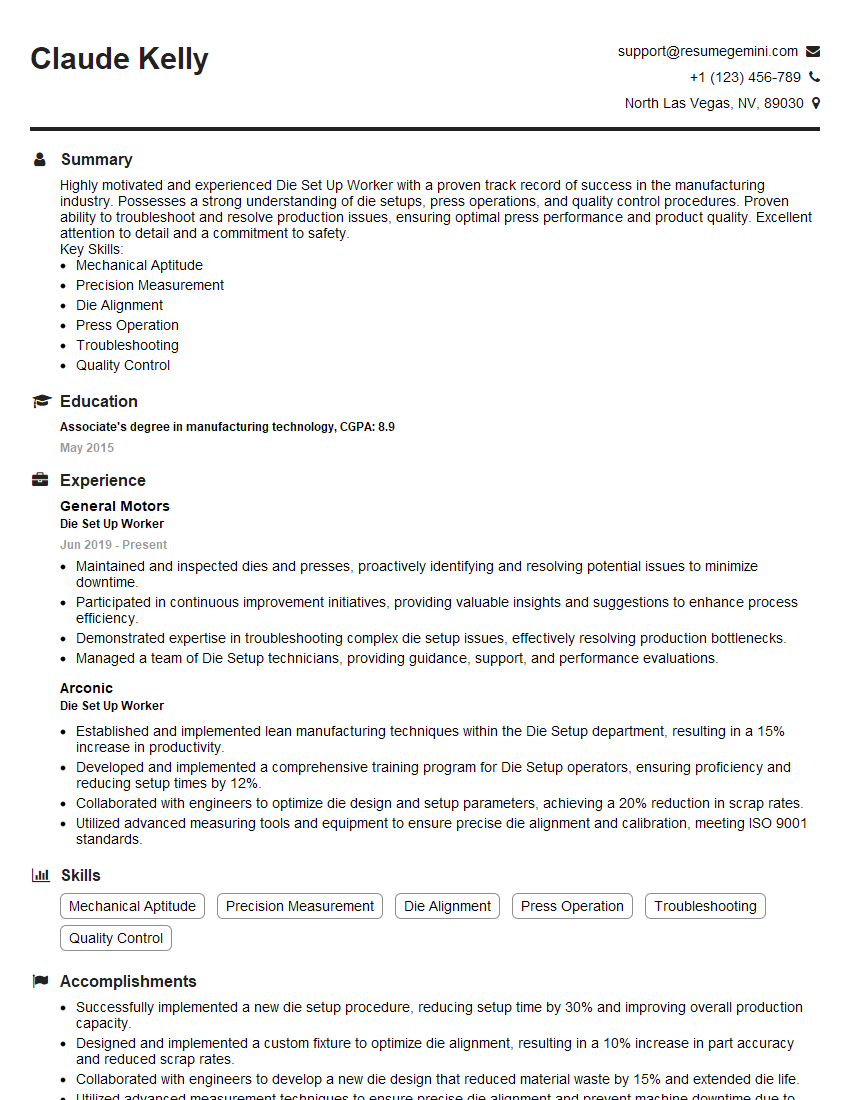

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Set Up Worker

1. What is the difference between a progressive die and a compound die?

A progressive die is a stamping tool that uses multiple dies to perform a series of metalworking operations in a single stroke of the press. Each die is responsible for a specific operation, such as cutting, forming, or piercing. A compound die, on the other hand, is a tool that uses multiple dies in a single press stroke to perform a series of operations on the same part. The operations are performed progressively as the part moves through the die.

2. What is the purpose of a stripper plate?

To prevent the part from sticking to the die

- Stripper plates are used in progressive dies and compound dies to prevent the part from sticking to the die after it has been formed.

To strip the part from the die

- Stripper plates are also used to strip the part from the die after it has been formed.

3. What is the importance of proper die alignment?

Proper die alignment is important for several reasons:

- To ensure that the part is formed correctly

- To prevent the dies from being damaged

- To prolong the life of the dies

4. What are the different types of die clearances?

The different types of die clearances are:

- Shear clearance

- Cutting clearance

- Forming clearance

- Piercing clearance

5. What is the purpose of a die cushion?

A die cushion is used to protect the lower die from damage. It also helps to prevent the part from being deformed during the forming process.

6. What are the different types of die sets?

The different types of die sets are:

- Two-piece die sets

- Three-piece die sets

- Four-piece die sets

7. What is the difference between a die set and a die shoe?

A die set is a complete set of dies that are used to make a specific part. A die shoe is a part of a die set that holds the dies in place.

8. What are the different types of die materials?

The different types of die materials are:

- Tool steel

- Carbide

- Ceramic

- Plastic

9. What are the different types of die coatings?

The different types of die coatings are:

- Nitriding

- Carburizing

- Titanium nitride coating

- Chromium nitride coating

10. What are the different types of press brakes?

The different types of press brakes are:

- Mechanical press brakes

- Hydraulic press brakes

- Pneumatic press brakes

- Servo-electric press brakes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Set Up Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Set Up Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Die Set Up Worker is a highly skilled professional responsible for preparing and setting up dies for use in stamping, forming, and other metalworking processes. Their primary responsibilities include:

1. Die Setup and Maintenance

Installing, adjusting, and aligning dies to ensure proper operation of stamping presses and other equipment.

- Preparing and setting up dies according to engineering specifications.

- Conducting routine inspections and preventive maintenance on dies to ensure optimal performance.

2. Material Handling and Quality Control

Loading and unloading raw materials, finished products, and dies from presses and other equipment.

- Inspecting finished products for quality and accuracy, ensuring they meet specifications.

- Identifying and resolving production issues related to die setup or material quality.

3. Troubleshooting and Problem Solving

Diagnosing and resolving issues with die setups, equipment malfunctions, and production defects.

- Identifying and addressing root causes of production issues to improve efficiency and reduce downtime.

- Working closely with engineers, production managers, and quality control personnel to resolve complex problems.

4. Safety and Compliance

Ensuring compliance with safety regulations and procedures to maintain a safe and productive work environment.

- Following established safety protocols and wearing appropriate personal protective equipment.

- Maintaining a clean and organized work area, free of hazards and debris.

Interview Tips

To ace your interview for a Die Set Up Worker position, follow these tips:

1. Research the Company and Industry

Demonstrate your interest in the company and their industry by researching their products, services, and recent news.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay informed about trends and developments.

2. Practice Your Technical Skills

Review your knowledge of die setup procedures, troubleshooting techniques, and quality control principles.

- Practice setting up dies on a simulated or actual press, if possible.

- Prepare examples of how you have identified and resolved production issues in the past.

3. Highlight Your Experience

Emphasize your relevant experience in die setup, metalworking, or a related field.

- Quantify your accomplishments using specific metrics, such as the number of dies you have set up or the percentage of defective products you have reduced.

- Describe your ability to work independently and as part of a team.

4. Be Prepared to Discuss Safety and Compliance

Demonstrate your understanding of safety regulations and procedures related to die setup and metalworking.

- Explain how you ensure compliance with safety protocols and maintain a safe work environment.

- Discuss your experience in identifying and mitigating potential hazards in the workplace.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Die Set Up Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.