Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Die Sinker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Die Sinker so you can tailor your answers to impress potential employers.

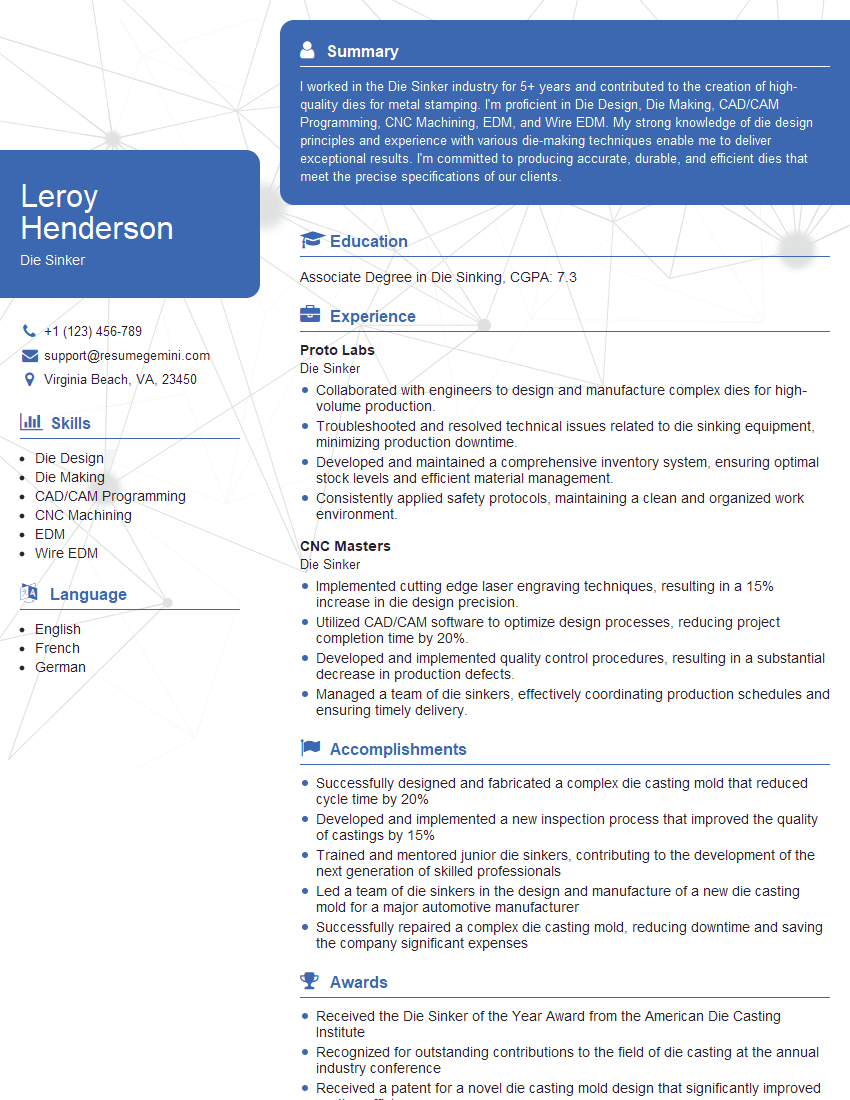

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Sinker

1. Explain the process of die sinking, including the different types of dies and materials used?

Die sinking is a subtractive manufacturing process used to create dies used in metal stamping, forging, and other forming operations. There are two main types of dies: single-impression dies and multiple-impression dies. Single-impression dies create one part at a time, while multiple-impression dies create multiple parts at a time. Dies can be made from a variety of materials, including tool steel, alloy steel, and carbide.

- The process of die sinking begins with creating a design for the die. The design is then used to create a master pattern, which is a physical representation of the die. The master pattern is used to create a working mold, which is used to cast the die.

- Once the die is cast, it is heat treated and ground to achieve the desired shape and dimensions. The die is then polished and inspected before being put into use.

2. Describe the different types of die sinking machines and their applications?

There are two main types of die sinking machines: ram type and plunge type. Ram type machines use a vertically moving ram to press the cutting tool into the workpiece. Plunge type machines use a horizontally moving plunger to press the cutting tool into the workpiece.

Ram type machines

- Ram type machines are typically used for larger dies and for operations that require high precision.

- Ram type machines can be equipped with a variety of cutting tools, including end mills, ball mills, and fly cutters.

Plunge type machines

- Plunge type machines are typically used for smaller dies and for operations that require less precision.

- Plunge type machines are typically equipped with end mills and ball mills.

3. What are the different types of cutting tools used in die sinking and their applications?

The type of cutting tool used in die sinking depends on the material being cut and the desired shape of the die. Some of the most common types of cutting tools used in die sinking include:

- End mills are used to create straight cuts and slots.

- Ball mills are used to create curved cuts and shapes.

- Fly cutters are used to create large, flat surfaces.

- Hobs are used to create gears.

- Form tools are used to create complex shapes.

4. What are the different factors that affect the quality of a die sinking operation?

The quality of a die sinking operation depends on a number of factors, including:

- The type of die sinking machine used

- The type of cutting tool used

- The material being cut

- The speed and feed rate of the cutting tool

- The depth of cut

- The geometry of the die

- The skill of the die sinker

5. What are the different inspection methods used for die sinking operations?

The quality of a die sinking operation is inspected using a variety of methods, including:

- Visual inspection

- Dimensional inspection

- Surface roughness inspection

- Tool wear inspection

- Die life testing

6. What are the different safety precautions that must be taken when operating a die sinking machine?

When operating a die sinking machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Ensure that the machine is properly set up and calibrated.

- Inspect the cutting tool before each use.

- Secure the workpiece properly.

- Start the machine slowly and gradually increase the speed and feed rate.

- Never reach into the machine while it is operating.

- Be aware of the location of the emergency stop button.

7. What are the different types of maintenance that must be performed on a die sinking machine?

Die sinking machines require regular maintenance to ensure optimal performance and safety. Some of the most common maintenance tasks include:

- Cleaning the machine

- Lubricating the machine

- Inspecting the cutting tool

- Calibrating the machine

- Replacing worn parts

8. What are the different skills and knowledge required to be a successful die sinker?

Successful die sinkers typically have the following skills and knowledge:

- Knowledge of die sinking machines and cutting tools

- Experience with different types of materials

- Ability to read and interpret blueprints

- Strong attention to detail

- Good problem-solving skills

- Ability to work independently and as part of a team

9. What are the different career opportunities for die sinkers?

Die sinkers can work in a variety of industries, including automotive, aerospace, and medical. They can also work in machine shops, tool and die shops, and manufacturing plants. Some die sinkers may choose to start their own businesses.

10. What are the different training and education requirements for die sinkers?

There are a variety of training and education programs available for die sinkers. Some programs are offered by community colleges and technical schools, while others are offered by private training providers. Some die sinkers may also choose to learn the trade through an apprenticeship program.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Sinker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Sinker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die Sinkers are skilled craftspeople responsible for creating and maintaining dies used in various manufacturing processes, including forging, stamping, and casting. Their primary duties include:

1. Die Design and Creation

Collaborate with engineers and designers to develop and refine die designs.

- Use specialized software to create 3D models and technical drawings of dies.

- Select appropriate materials and determine the optimal manufacturing methods.

2. Die Machining and Fabrication

Operate various machine tools, including CNC milling machines, lathes, and grinders.

- Machine and shape die components with precision to tight tolerances.

- Apply heat treatment and other surface treatments to enhance die durability.

3. Die Maintenance and Repair

Inspect and maintain dies regularly to ensure optimal performance.

- Identify and repair wear and damage in dies.

- Adjust and modify dies as needed to maintain production quality.

4. Quality Control

Conduct quality checks on manufactured parts produced using dies.

- Measure and analyze dimensions, tolerances, and surface finishes.

- Identify and troubleshoot issues with die performance.

Interview Tips

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company’s products, services, and industry trends.

2. Highlight Your Technical Skills

Emphasize your proficiency in die design software, machining techniques, and quality control procedures.

3. Showcase Your Problem-Solving Abilities

Provide examples of how you overcame challenges in previous die-making projects.

4. Prepare for Technical Questions

Be ready to answer questions about die design principles, machining processes, and quality control standards.

5. Practice Your Communication Skills

Effectively convey your technical knowledge and ideas to both technical and non-technical interviewers.

6. Research the Company’s Culture

Learn about the company’s values, work environment, and career growth opportunities.

7. Prepare Relevant Questions

Ask thoughtful questions that show your interest in the role and the company.

8. Dress Professionally

Make a good first impression by dressing appropriately for the interview.

9. Be Punctual

Arrive on time for your interview to demonstrate your respect for the interviewers’ time.

10. Follow Up

Send a thank-you note after the interview, reiterating your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Sinker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!