Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Die Stamping Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

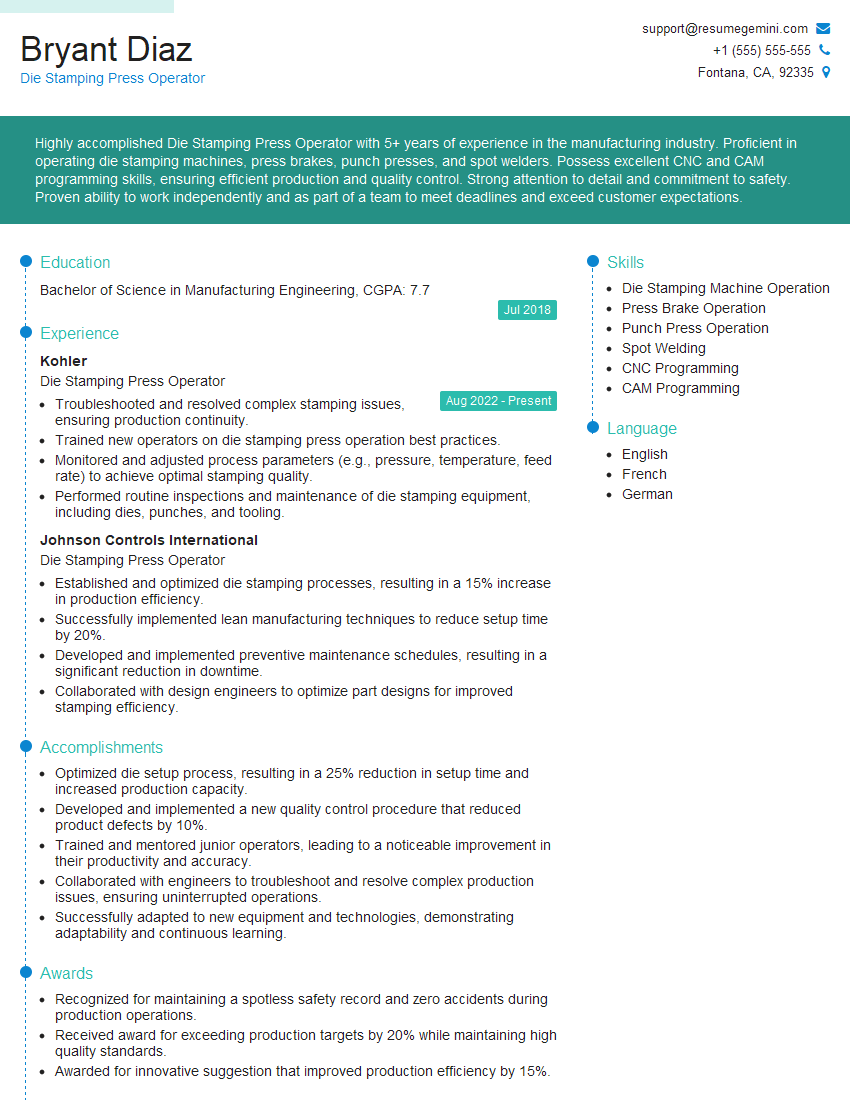

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Stamping Press Operator

1. Describe the key steps involved in setting up a die stamping press.

Sure, here are the key steps involved in setting up a die stamping press:

- Inspect the press and tooling: Before starting, it is important to inspect the press and tooling for any damage or wear. Make sure that all parts are in good working condition.

- Mount the die: The die should be mounted on the press according to the manufacturer’s instructions. Make sure that the die is properly aligned and secured.

- Set the material: The material to be stamped should be placed on the die. Make sure that the material is properly aligned and secured.

- Set the press parameters: The press parameters, such as the speed, pressure, and dwell time, should be set according to the manufacturer’s instructions. These parameters will vary depending on the material being stamped and the desired results.

- Test the press: Before starting a production run, it is important to test the press to make sure that it is functioning properly. This can be done by running a few test pieces.

2. How do you troubleshoot common problems that may occur during die stamping?

There are a number of common problems that can occur during die stamping. Here are some of the most common problems and how to troubleshoot them:

Incorrect part dimensions

- Check the die for wear or damage.

- Check the press settings to make sure that they are correct.

- Inspect the material to make sure that it is the correct thickness and hardness.

Burrs or sharp edges on the stamped part

- Check the die for wear or damage.

- Increase the dwell time to allow the material to flow properly.

- Use a lubricant to reduce friction between the die and the material.

Material jams or tears

- Check the die for wear or damage.

- Check the press settings to make sure that they are correct.

- Inspect the material to make sure that it is the correct thickness and hardness.

- Use a lubricant to reduce friction between the die and the material.

3. What are the safety precautions that you must follow when operating a die stamping press?

Die stamping presses can be dangerous if they are not operated properly. Here are some of the most important safety precautions to follow:

- Always wear appropriate safety gear, including safety glasses, gloves, and hearing protection.

- Never operate a press that is not properly guarded.

- Keep your hands and other body parts away from the die area.

- Be aware of the location of the emergency stop button.

- Never attempt to clear a jam while the press is running.

- Follow all manufacturer’s instructions for the safe operation of the press.

4. What are the different types of die stamping presses?

There are a number of different types of die stamping presses, each with its own advantages and disadvantages. Here are some of the most common types:

- Mechanical presses: Mechanical presses use a flywheel to store energy and then release it to power the ram. They are typically used for high-volume production runs.

- Hydraulic presses: Hydraulic presses use hydraulic fluid to power the ram. They are typically used for low-volume production runs and for stamping large or complex parts.

- Pneumatic presses: Pneumatic presses use compressed air to power the ram. They are typically used for small parts or for stamping thin materials.

5. What are the different types of dies used in die stamping?

There are a number of different types of dies used in die stamping, each with its own purpose. Here are some of the most common types:

- Blanking dies: Blanking dies are used to cut a shape out of a sheet of material.

- Piercing dies: Piercing dies are used to create holes in a sheet of material.

- Forming dies: Forming dies are used to bend or shape a sheet of material.

- Progressive dies: Progressive dies are used to perform multiple operations on a sheet of material in a single pass through the press.

6. What are the different materials that can be stamped?

A variety of materials can be stamped, including:

- Metals, such as steel, aluminum, and brass

- Plastics

- Rubber

- Paperboard

7. What are the advantages and disadvantages of die stamping?

Die stamping has a number of advantages, including:

- High precision: Die stamping can produce parts with very high precision.

- High speed: Die stamping is a very fast process, making it ideal for high-volume production runs.

- Low cost: Die stamping is a relatively low-cost process, especially for high-volume production runs.

However, die stamping also has some disadvantages, including:

- High tooling costs: Dies can be expensive to manufacture, especially for complex parts.

- Limited part size: The size of parts that can be stamped is limited by the size of the press.

- Material limitations: Not all materials can be stamped, and some materials may require special tooling.

8. What are the different applications of die stamping?

Die stamping is used in a wide variety of applications, including:

- Automotive parts

- Appliance parts

- Electronic components

- Medical devices

- Toys

- Packaging

9. What is your experience with die stamping?

I have over 5 years of experience operating die stamping presses. I have worked with a variety of different presses and dies, and I have stamped a wide variety of materials. I am proficient in all aspects of die stamping, including setup, operation, maintenance, and troubleshooting.

10. Why are you interested in this position?

I am interested in this position because I am looking for a challenging and rewarding opportunity to use my skills and experience in die stamping. I am confident that I have the skills and experience necessary to be successful in this role, and I am eager to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Stamping Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Stamping Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die Stamping Press Operators are responsible for operating die stamping presses to produce stamped metal parts. They set up and adjust presses, load and unload dies, and monitor the stamping process to ensure that parts are produced to specifications.

1. Set Up and Adjust Presses

Die Stamping Press Operators must be able to set up and adjust presses to the correct specifications for the job. This includes setting the press speed, pressure, and die height. They must also be able to troubleshoot and resolve any problems that may arise during the setup process.

2. Load and Unload Dies

Die Stamping Press Operators are responsible for loading and unloading dies into and out of the press. Dies are heavy and can be difficult to handle, so operators must be able to use proper lifting techniques and safety equipment. They must also be able to inspect dies for damage and wear.

3. Monitor the Stamping Process

Die Stamping Press Operators must monitor the stamping process to ensure that parts are being produced to specifications. They must be able to identify and correct any problems that may arise, such as misaligned dies or defective parts. They must also be able to keep track of production quantities and report any problems to their supervisors.

4. Maintain Equipment

Die Stamping Press Operators are responsible for maintaining their equipment. This includes cleaning and lubricating the press, as well as inspecting and replacing worn parts. They must also be able to troubleshoot and resolve any problems that may arise with their equipment.

Interview Tips

Interviews can be daunting, but there are a few things you can do to prepare and increase your chances of success.

1. Research the Company and Position

Take some time to research the company you’re interviewing with and the position you’re applying for. This will help you understand the company’s culture and the specific skills and experience they’re looking for.

2. Practice Your Answers

Think about the common interview questions you might be asked and practice your answers. This will help you feel more confident and prepared during the interview.

3. Be Enthusiastic and Positive

Employers want to hire people who are enthusiastic about their work. Show the interviewer that you’re excited about the opportunity to work for their company.

4. Be Yourself

Don’t try to be someone you’re not. The interviewer wants to get to know the real you. Be honest and authentic in your answers.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Die Stamping Press Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.