Feeling lost in a sea of interview questions? Landed that dream interview for Die Welder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Die Welder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

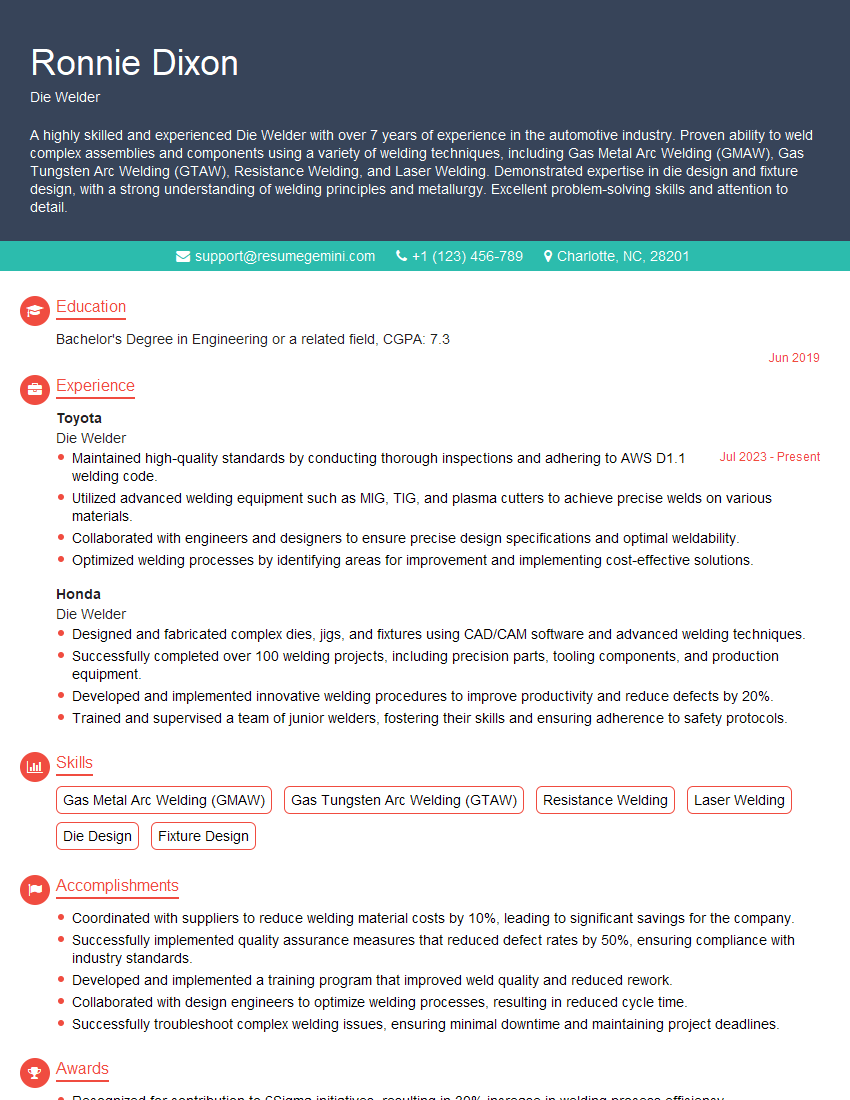

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Welder

1. What are the different types of welding processes that you are familiar with?

- Arc welding, GMAW, GTAW, SAW, FCAW, SMAW

- Resistance welding, spot welding, seam welding, projection welding, flash welding

2. What are the different types of welds that can be made with an arc welding process?

- Fillet weld

- Butt weld

- Edge weld

- Corner weld

- T-weld

3. What are the key factors that determine the quality of a weld?

- Proper joint preparation

- Correct welding parameters

- Adequate welding skills

- Suitable welding materials

- Post-weld treatments

4. What are the different types of welding defects?

- Cracks

- Porosity

- Lack of fusion

- Undercutting

- Overlapping

5. What are the safety precautions that must be taken when welding?

- Wear appropriate safety gear, including welding helmet, gloves, and clothing

- Ensure proper ventilation in the welding area

- Inspect equipment regularly for any defects or damage

- Handle hazardous materials safely

- Follow safe work practices and procedures

6. What are your experiences working with different types of materials, such as mild steel, stainless steel, or aluminum?

- Extensive experience in welding mild steel, including various thicknesses and configurations

- Proficient in welding stainless steel, with an understanding of its unique properties and requirements

- Familiar with welding aluminum, utilizing proper techniques and filler materials

7. What is your understanding of welding codes and standards, such as AWS or ASME?

- Thorough knowledge of AWS (American Welding Society) codes and standards

- Familiarity with ASME (American Society of Mechanical Engineers) Boiler and Pressure Vessel Code

- Ability to interpret and apply these codes to ensure compliance

8. What techniques do you use to ensure the accuracy and precision of your welding work?

- Utilizing precision measuring tools and gauges

- Following detailed blueprints and specifications

- Employing specialized welding techniques, such as tack welding and fixturing

- Regularly calibrating welding equipment

9. Have you used any specialized welding equipment or techniques, such as robotic welding or underwater welding?

- Experience in operating robotic welding systems, ensuring accuracy and efficiency

- Proficient in underwater welding techniques, utilizing specialized equipment and procedures

- Familiar with other specialized welding equipment, such as plasma cutters and laser welders

10. How do you stay updated with the latest welding technologies and best practices?

- Regularly attend industry conferences and workshops

- Read technical publications and online resources

- Participate in professional development programs

- Seek mentorship from experienced welders

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die welders are responsible for creating and repairing dies, which are metal tools used to shape other metal parts. Their key responsibilities include:

1. Die Design and Fabrication

- Interpreting blueprints and engineering drawings to understand the specifications of the die being built.

- Selecting and cutting the appropriate materials for the die, based on its intended use and the properties of the metal being formed.

- Fabricating the die components, using various welding techniques, such as TIG, MIG, and stick welding.

2. Die Maintenance and Repair

- Inspecting dies for wear and damage, and performing maintenance tasks, such as cleaning, lubrication, and minor repairs.

- Repairing damaged dies, using welding and other metalworking techniques, ensuring that they meet the required specifications.

3. Quality Control

- Conducting quality checks on dies, using precision measuring instruments, to ensure that they meet the required tolerances and specifications.

- Working closely with engineers and production teams to ensure that dies are properly installed and operating efficiently.

4. Safety and Compliance

- Following established safety protocols and guidelines while working with welding equipment and materials.

- Ensuring that all dies are manufactured and maintained in compliance with industry standards and regulations.

Interview Tips

To ace an interview for a Die Welder position, it’s crucial to prepare thoroughly. Here are some interview tips and hacks:

1. Research the Company and Position

- Learn about the company’s history, products, and industry standing.

- Identify the specific requirements and expectations of the Die Welder role.

2. Highlight Relevant Skills and Experience

- Emphasize your proficiency in different welding techniques, especially those relevant to die welding.

- Showcase your understanding of die design and fabrication processes.

- Demonstrate your experience in die maintenance and repair, including troubleshooting and problem-solving abilities.

3. Prepare for Technical Questions

- Review welding terminology, materials, and equipment.

- Practice answering questions related to die design, fabrication, and maintenance.

- Be ready to discuss your knowledge of welding codes and standards.

4. Practice Your Presentation

- Prepare a clear and concise introduction that highlights your key qualifications.

- Use specific examples to demonstrate your skills and experience.

- Practice answering common interview questions confidently and articulately.

5. Dress Professionally and Be Punctual

- Dress in appropriate attire that reflects the professional nature of the role.

- Arrive on time for your interview, demonstrating your punctuality and respect for the interviewer’s time.

- Be enthusiastic and show genuine interest in the position and the company.

6. Ask Thoughtful Questions

- Prepare questions that demonstrate your engagement and interest in the role.

- Ask about the company’s culture, training opportunities, and career advancement prospects.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!