Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Diesel Engine Erector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Diesel Engine Erector so you can tailor your answers to impress potential employers.

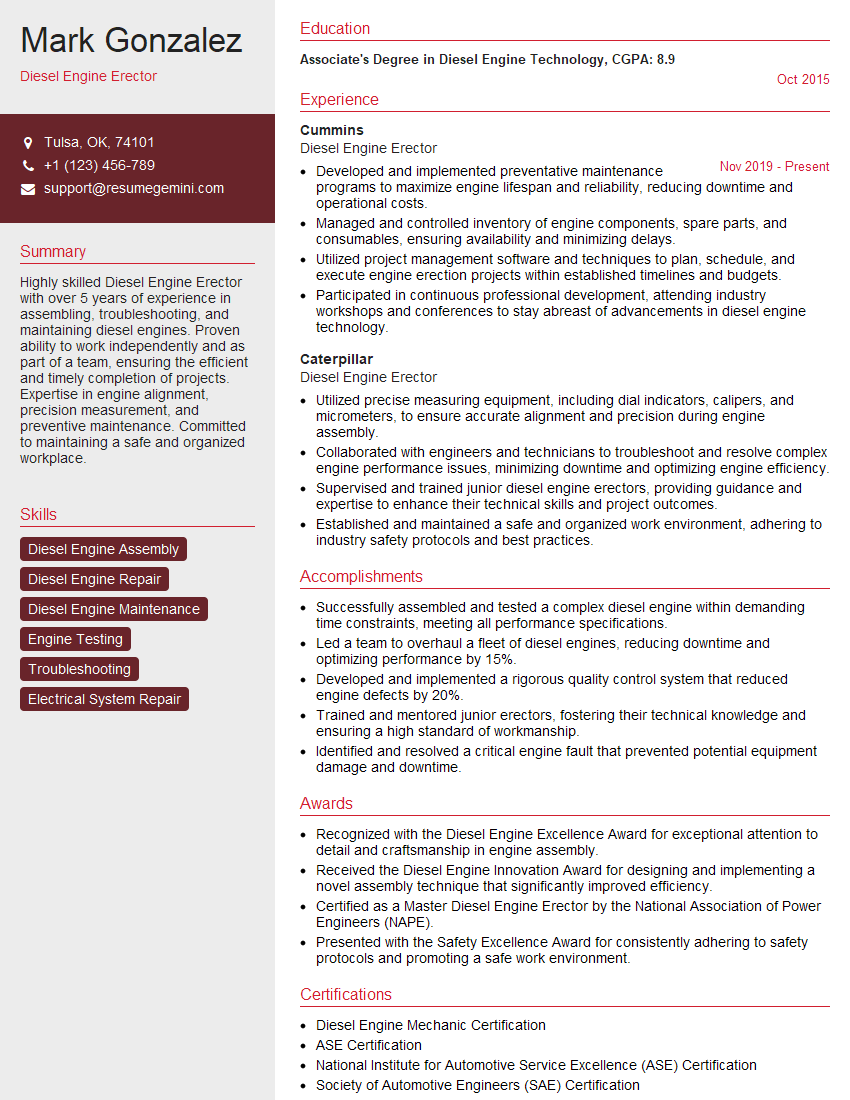

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diesel Engine Erector

1. Describe the steps involved in assembling a diesel engine from its components.

- Inspect and prepare engine components, including pistons, cylinder heads, and crankshaft.

- Install connecting rods on crankshaft and secure with bolts.

- Fit pistons into cylinders and secure with piston rings.

- Install cylinder head gasket and cylinder head, torquing bolts to specifications.

- Connect timing gears, valves, and fuel injection system.

- Lubricate and align engine components and verify clearances.

- Install oil pump, oil filter, and starter.

- Connect electrical wiring and fuel lines.

- Conduct pre-start checks and ensure proper functionality.

2. How do you troubleshoot and repair a diesel engine that is experiencing excessive exhaust smoke?

Inspect Engine Components

- Check fuel injector nozzles for leaks or damage.

- Examine air filter for clogging.

- Inspect turbocharger for proper operation.

Diagnose Cause

- Determine if smoke is black, indicating rich fuel mixture, or blue, suggesting oil burning.

- Use diagnostic tools such as a fuel pressure gauge and exhaust gas analyzer.

- Observe engine behavior under different operating conditions.

Implement Repairs

- Replace faulty fuel injector nozzles.

- Clean or replace air filter.

- Repair or replace turbocharger.

- Adjust fuel injection system parameters.

3. Explain the process for performing a valve adjustment on a diesel engine.

- Locate and access valve tappets.

- Use feeler gauges to measure valve clearance.

- Adjust tappets by tightening or loosening locknuts.

- Recheck valve clearance and verify proper adjustment.

- Follow manufacturer’s specifications for valve clearances and adjustment procedures.

4. How do you measure and adjust the timing of a diesel engine?

- Use a timing light or dial indicator to determine engine timing.

- Compare measured timing to manufacturer’s specifications.

- Adjust timing by rotating crankshaft or camshaft as necessary.

- Secure timing components and recheck timing for accuracy.

5. Describe the procedures for replacing a crankshaft in a diesel engine.

Preparations

- Remove engine from vehicle or machinery.

- Disassemble engine components as needed.

Crankshaft Removal

- Disconnect and remove flywheel or flexplate.

- Remove crankshaft bearings and seals.

- Extract crankshaft carefully using a crane or hoist.

Crankshaft Installation

- Lubricate and install new crankshaft bearings and seals.

- Lower new crankshaft into position and secure it.

- Install flywheel or flexplate.

Reassembly and Checks

- Reassemble engine components in reverse order.

- Perform crankshaft end play and journal bearing clearance checks.

- Reinstall engine and conduct pre-start checks.

6. Discuss the maintenance procedures for ensuring optimal performance of a diesel engine.

- Regular oil and filter changes.

- Air filter inspections and replacements.

- Fuel system maintenance, including injector cleaning and filter changes.

- Cooling system inspections and coolant flushes.

- Valve adjustments and timing checks.

- Belt and hose inspections and replacements.

- Monitoring engine performance and identifying potential issues early.

7. How do you interpret diesel engine diagnostic codes?

- Use a scan tool or diagnostic software to retrieve codes.

- Refer to manufacturer’s service manual for code definitions.

- Analyze code symptoms and potential causes.

- Perform targeted inspections and tests to identify and resolve underlying issues.

- Clear codes and verify repairs by retesting.

8. Explain the safety precautions to be observed while working on diesel engines.

- Wear appropriate personal protective equipment (PPE).

- Lock out and tag out power sources.

- Avoid working on hot engines or components.

- Handle fuel and lubricants carefully.

- Use proper lifting techniques to prevent injuries.

- Be aware of potential hazards and maintain a clean and organized work area.

9. Discuss the latest trends and advancements in diesel engine technology.

- Electronic fuel injection and engine management systems.

- Turbocharging and intercooling for increased efficiency.

- Diesel particulate filters (DPFs) to reduce emissions.

- Selective catalytic reduction (SCR) systems for NOx reduction.

- Hybrid and electric diesel powertrains.

10. How do you keep up-to-date with the latest developments in diesel engine technology?

- Attend industry conferences and workshops.

- Read technical publications and online resources.

- Stay informed about manufacturer updates and service bulletins.

- Participate in online forums and discussion groups.

- Seek opportunities for training and certification.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diesel Engine Erector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diesel Engine Erector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diesel Engine Erectors play a crucial role in assembling, erecting, dismantling, and maintaining diesel engines. Their responsibilities are critical to ensuring the smooth operation of diesel-powered equipment in various industries.

1. Assembly and Erection

Erectors are responsible for assembling diesel engines according to specifications.

- Follow blueprints and technical drawings

- Install and align components

2. Installation and Commissioning

Once assembled, erectors install diesel engines on various platforms or within equipment.

- Prepare sites and foundations

- Connect engines to fuel, electrical, and other systems

3. Maintenance and Repair

Erectors conduct regular maintenance and repairs to ensure optimal engine performance.

- Inspect and evaluate engines

- Identify and resolve mechanical issues

4. Troubleshooting

In case of malfunctions or breakdowns, erectors diagnose and troubleshoot problems.

- Use diagnostic tools and equipment

- Resolve issues and ensure engine efficiency

Interview Tips

To ace an interview for a Diesel Engine Erector position, candidates should prepare thoroughly and showcase their technical skills and industry knowledge.

1. Highlight Your Experience

Emphasize your previous experience in engine assembly, erection, or maintenance.

- Quantify your accomplishments with specific numbers and metrics

- Provide examples of complex projects or challenges you handled successfully

2. Demonstrate Technical Knowledge

Exhibit your understanding of diesel engine principles, components, and systems.

- Explain the working principles of diesel engines

- Discuss common troubleshooting methods and techniques

3. Show Safety Consciousness

Safety is paramount in working with diesel engines.

- Highlight your adherence to safety protocols and regulations

- Describe your experience with hazard identification and risk assessment

4. Practice Common Interview Questions

Review common interview questions and prepare your answers.

- “Tell us about your experience in diesel engine erection”

- “What are the key challenges you face in your work?”

- “How do you stay up-to-date with the latest industry advancements?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Diesel Engine Erector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.