Are you gearing up for a career in Diesel Engine Fitter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Diesel Engine Fitter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

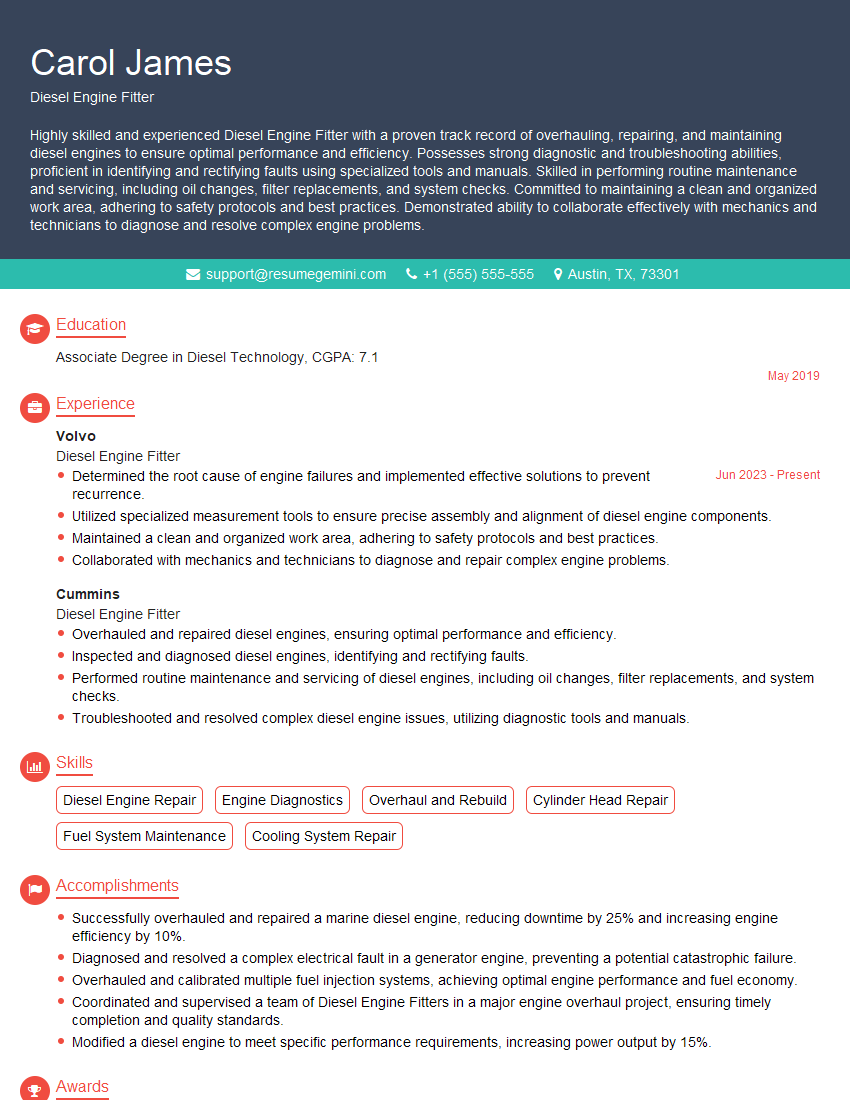

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diesel Engine Fitter

1. Describe the major components of a diesel engine and their functions?

A diesel engine consists of the following major components, and their functions are as follows:

- Cylinder block: Houses the cylinders, where the pistons move up and down.

- Cylinder head: Covers the top of the cylinders and forms the combustion chamber.

- Pistons: Move up and down inside the cylinders, compressing the air-fuel mixture and generating power.

- Connecting rods: Connect the pistons to the crankshaft, converting the reciprocating motion of the pistons into rotational motion.

- Crankshaft: Converts the reciprocating motion of the pistons into rotational motion, which is then transmitted to the rest of the engine’s components.

- Camshaft: Controls the timing of the valves, which open and close to allow air and fuel into the cylinders and exhaust gases out.

- Fuel injection system: Delivers fuel to the cylinders at the appropriate time and pressure.

- Air intake system: Draws air into the engine and filters it before it enters the cylinders.

- Exhaust system: Removes exhaust gases from the engine and reduces their emissions.

2. Explain the difference between a two-stroke and a four-stroke diesel engine?

Two-stroke engine

- Completes one power cycle in two strokes (one revolution of the crankshaft).

- Intake and exhaust valves are controlled by ports in the cylinder walls.

- Less efficient than four-stroke engines but lighter and more compact.

Four-stroke engine

- Completes one power cycle in four strokes (two revolutions of the crankshaft).

- Intake and exhaust valves are controlled by camshafts and rocker arms.

- More efficient than two-stroke engines but heavier and larger.

3. Describe the process of overhauling a diesel engine?

Overhauling a diesel engine involves the following steps:

- Disassembly: The engine is disassembled into its major components.

- Inspection: The components are inspected for wear and damage.

- Cleaning: The components are cleaned to remove any dirt or debris.

- Repair or replacement: Worn or damaged components are repaired or replaced.

- Reassembly: The engine is reassembled, and all components are torqued to the correct specifications.

- Testing: The engine is tested to ensure that it is operating properly.

4. What are the common problems that can occur with diesel engines and how can they be prevented?

Common problems that can occur with diesel engines include:

- Excessive fuel consumption: Can be caused by a variety of factors, such as worn injectors, a dirty air filter, or a faulty fuel pump.

- Loss of power: Can be caused by a variety of factors, such as a clogged fuel filter, a faulty turbocharger, or a worn piston rings.

- Excessive smoke: Can be caused by a variety of factors, such as a faulty injector, a worn piston rings, or a dirty air filter.

- Engine overheating: Can be caused by a variety of factors, such as a clogged radiator, a faulty water pump, or a leaking head gasket.

These problems can be prevented by following proper maintenance procedures, such as regularly changing the oil and filter, using clean fuel, and keeping the engine clean.

5. What tools and equipment are essential for a diesel engine fitter?

Essential tools and equipment for a diesel engine fitter include:

- Wrenches: Used to tighten and loosen nuts and bolts.

- Screwdrivers: Used to tighten and loosen screws.

- Pliers: Used to grip and hold objects.

- Measuring tapes: Used to measure the size of objects.

- Micrometers: Used to measure the thickness of objects.

- Dial calipers: Used to measure the diameter of objects.

- Engine hoists: Used to lift and move engines.

- Engine stands: Used to support engines during maintenance and repair.

- Diagnostic tools: Used to troubleshoot and diagnose engine problems.

6. What are the safety precautions that should be taken when working on diesel engines?

Safety precautions that should be taken when working on diesel engines include:

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Ensure that the engine is turned off and cooled down before performing any work.

- Do not smoke or use open flames around diesel engines.

- Be aware of the potential for burns and cuts.

- Use caution when lifting and moving heavy objects.

- Follow all manufacturer’s instructions and safety guidelines.

7. What are the latest trends in diesel engine technology?

The latest trends in diesel engine technology include:

- Increased use of electronics: Diesel engines are becoming increasingly electronic, with more and more functions being controlled by computer.

- Higher efficiency: Diesel engines are becoming more efficient, thanks to advances in fuel injection technology and turbocharging.

- Lower emissions: Diesel engines are becoming cleaner, thanks to the use of advanced emission control systems.

- Alternative fuels: Diesel engines are being developed to run on alternative fuels, such as biodiesel and natural gas.

8. What are the challenges facing diesel engine fitters?

The challenges facing diesel engine fitters include:

- The need to stay up-to-date with the latest technology: Diesel engines are becoming increasingly complex, and fitters need to stay up-to-date with the latest technology to be able to service and repair them.

- The need to work with a variety of engines: Diesel engines are used in a wide range of applications, and fitters need to be able to work on a variety of engines.

- The need to work in a safe environment: Diesel engines can be dangerous, and fitters need to be able to work in a safe environment.

9. What is your experience with troubleshooting and repairing diesel engines?

I have experience with troubleshooting and repairing diesel engines in a variety of applications, including automotive, marine, and industrial. I am familiar with the most common problems that can occur with diesel engines, and I know how to diagnose and repair them quickly and efficiently. I also have experience with using diagnostic tools to troubleshoot engine problems.

10. What is your availability?

I am available to work immediately. I am flexible with my schedule and can work overtime or on weekends if necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diesel Engine Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diesel Engine Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Diesel Engine Fitter plays a vital role in maintaining and repairing diesel engines in various industries such as automotive, transportation, and power generation. Their key job responsibilities include:

1. Engine Inspection and Maintenance

Inspecting and diagnosing diesel engines for faults, wear and tear, and other issues.

- Conducting performance tests and analyzing data to identify potential problems.

- Carrying out routine maintenance tasks such as oil changes, filter replacements, and lubrication.

2. Engine Repair and Overhaul

Repairing and overhauling damaged or worn engine components.

- Disassembling engines to access and replace faulty parts.

- Rebuilding and reassembling engines to ensure optimal performance.

3. Engine Installation and Commissioning

Installing and commissioning new or repaired engines in vehicles, equipment, or power plants.

- Following manufacturer’s specifications and industry standards for installation.

- Testing and adjusting engines to ensure proper operation.

4. Troubleshooting and Problem Solving

Diagnosing and resolving engine problems to minimize downtime and ensure efficient operation.

- Analyzing engine data and symptoms to identify the root cause of issues.

- Implementing solutions and testing results to verify performance.

Interview Tips

To prepare for an interview as a Diesel Engine Fitter, it is essential to showcase your technical expertise, problem-solving skills, and attention to detail. Here are some tips to help you ace the interview:

1. Brush up on your technical knowledge

Review the fundamentals of diesel engines, including their components, operation, and maintenance procedures. Research industry standards and best practices to demonstrate your up-to-date knowledge.

- Highlight your understanding of engine design, fuel systems, and electrical systems.

- Discuss your experience in using diagnostic tools and specialized equipment.

2. Showcase your problem-solving abilities

Prepare to discuss your approach to troubleshooting and resolving engine problems. Provide specific examples of how you identified and fixed complex issues.

- Use the STAR method (Situation, Task, Action, Result) to articulate your experiences.

- Emphasize your ability to analyze data, determine the root cause, and implement effective solutions.

3. Demonstrate your attention to detail

Stress your meticulous approach to engine inspection, maintenance, and repair. Explain how you ensure accuracy and precision in your work.

- Mention your use of checklists and documentation procedures to ensure thoroughness.

- Share examples of how your attention to detail has prevented or resolved potential issues.

4. Highlight your teamwork and communication skills

Diesel Engine Fitters often work as part of a team. Showcase your ability to collaborate effectively and communicate clearly with colleagues and supervisors.

- Discuss your experience in working with mechanics, technicians, and engineers.

- Explain how you provide updates, troubleshoot issues, and resolve conflicts in a professional and timely manner.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Diesel Engine Fitter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Diesel Engine Fitter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.