Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Diesel Engine Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

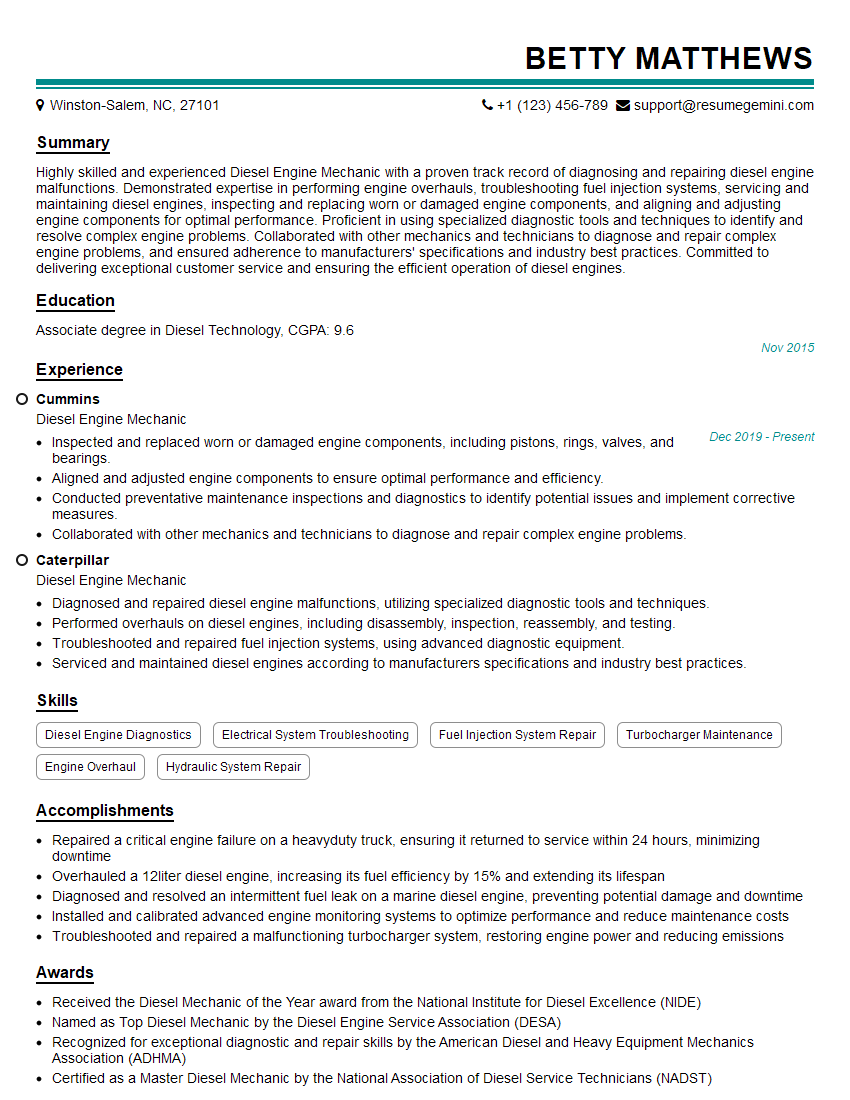

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diesel Engine Mechanic

1. What are the key components of a diesel engine and how do they work together?

- Pistons: Move up and down within the cylinders, compressing the air-fuel mixture and creating power.

- Cylinder head: Seals the combustion chamber and contains the valves that control airflow.

- Valves: Controlled by the camshaft to open and close, allowing air and fuel into the cylinder and exhaust gases out.

- Camshaft: Drives the valves using a timing chain or belt, ensuring the valves open and close at the correct time.

- Crankshaft: Converts the reciprocating motion of the pistons into rotational motion.

- Fuel injection system: Delivers fuel under high pressure into the cylinders at the right time.

- Turbocharger: Increases air density entering the cylinders, improving power output.

2. Explain the difference between two-stroke and four-stroke diesel engines.

Two-Stroke Engines

- Combustion and exhaust occur in one revolution.

- Fuel is mixed with the air before entering the cylinder.

- Exhaust ports are uncovered by the piston.

Four-Stroke Engines

- Combustion and exhaust occur in four revolutions.

- Fuel is injected directly into the cylinder.

- Valves control airflow and exhaust gas expulsion.

3. How do you troubleshoot a diesel engine that is not starting?

- Check for fuel supply and fuel filter condition.

- Test battery and starter for proper operation.

- Examine spark plugs or glow plugs.

- Verify timing belt or chain is intact.

- Listen for abnormal noises or vibrations.

4. What are the common causes of excessive smoke from a diesel engine?

- Faulty fuel injectors or injection timing.

- Worn or damaged turbocharger.

- Clogged air filter or exhaust system.

- Excessive oil consumption.

- Fuel system contamination.

5. Describe the steps involved in performing a preventive maintenance service on a diesel engine.

- Replace engine oil and filter.

- Inspect and clean air filter.

- Check and adjust valve clearances.

- Inspect fuel filters and lines.

- Test and replace spark plugs or glow plugs.

6. How do you adjust the governor on a diesel engine?

- Locate the governor mechanism.

- Check the manufacturer’s specifications for the desired speed setting.

- Adjust the governor linkage or screws to achieve the correct speed.

- Test the engine at various loads to ensure stability.

7. What are the safety precautions to observe when working on diesel engines?

- Wear personal protective equipment (PPE), including gloves, eye protection, and earplugs.

- Ensure the engine is turned off and disconnected from all power sources.

- Allow the engine to cool down before handling hot components.

- Use proper lifting equipment and avoid contact with heavy parts.

- Follow manufacturer’s instructions and observe all warning labels.

8. Explain the role of the turbocharger in a diesel engine and describe how it improves performance.

- The turbocharger increases air pressure entering the engine, improving oxygen availability.

- More oxygen allows for more efficient combustion, resulting in increased power.

- Turbochargers also reduce emissions by ensuring complete combustion.

- Turbocharged engines are more responsive and fuel-efficient than naturally aspirated engines.

9. What is the difference between direct injection and indirect injection diesel engines?

Direct Injection Engines

- Fuel is injected directly into the combustion chamber.

- Higher pressure and higher efficiency.

- Produces more torque at lower RPM.

Indirect Injection Engines

- Fuel is injected into a pre-combustion chamber before entering the combustion chamber.

- Lower pressure and lower efficiency.

- Produces smoother operation and lower noise.

10. How do you use diagnostic tools to identify and resolve faults in diesel engines?

- Use scan tools to read engine data and fault codes.

- Analyze fault codes to pinpoint the source of the problem.

- Perform diagnostic tests, such as compression tests and injector tests.

- Use data logs to monitor engine parameters and identify performance issues.

- Follow manufacturer’s guidelines and service manuals for accurate diagnostics.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diesel Engine Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diesel Engine Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diesel mechanics are responsible for the maintenance and repair of diesel engines and related components in various vehicles and industrial equipment.

1. Engine Inspection and Diagnostics

Inspect and diagnose diesel engines to identify malfunctions, defects, and potential issues.

- Perform compression and leakdown tests to check engine performance.

- Use diagnostic tools to analyze engine data and pinpoint problems.

2. Engine Repair and Overhaul

Carry out repairs and overhauls on diesel engines, including component replacement, rebuilding, and adjustments.

- Repair or replace engine components such as pistons, cylinders, crankshafts, and fuel injectors.

- Overhaul engines to restore them to optimal operating condition.

3. Maintenance and Preventive Care

Perform scheduled maintenance and preventive care on diesel engines to extend their lifespan and ensure reliable operation.

- Change oil, filters, and fluids according to manufacturer’s recommendations.

- Inspect and adjust engine components regularly to prevent potential issues.

4. Troubleshooting and Problem-Solving

Troubleshoot complex engine problems and provide solutions to restore proper engine function.

- Analyze engine data and identify root causes of malfunctions.

- Develop and implement repair strategies to resolve engine issues.

Interview Tips

To ace the interview, it’s crucial to prepare thoroughly and showcase your knowledge and skills effectively.

1. Research the Company and Position

Demonstrate your interest and understanding by researching the company’s industry, products, and specific role requirements.

- Review the job description carefully and identify key responsibilities and qualifications.

- Check the company website, LinkedIn page, and industry news for relevant information.

2. Quantify Your Experience

Use specific metrics and data to highlight your accomplishments and quantify your contributions.

- Example: “Reduced engine downtime by 25% through proactive maintenance and timely repairs.”

- Example: “Improved fuel efficiency by 10% by implementing optimized fuel injection settings.”

3. Highlight Your Skills and Training

Emphasize your relevant skills, certifications, and any specialized training or experience that sets you apart.

- List your expertise in engine diagnostics, repair techniques, and preventive maintenance.

- Mention any certifications or licenses you hold, such as ASE or OEM certifications.

4. Prepare for Technical Questions

Expect technical questions that assess your knowledge and problem-solving abilities.

- Example: “Discuss the common causes of engine vibration and explain how you diagnose and fix them.”

- Example: “Describe the steps involved in overhauling a diesel engine and explain the key quality control measures.”

5. Practice Your Interview Skills

Practice answering common interview questions aloud to build confidence and improve your delivery.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers effectively.

- Prepare answers to questions about your strengths, weaknesses, and career goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Diesel Engine Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.