Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Diesel Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

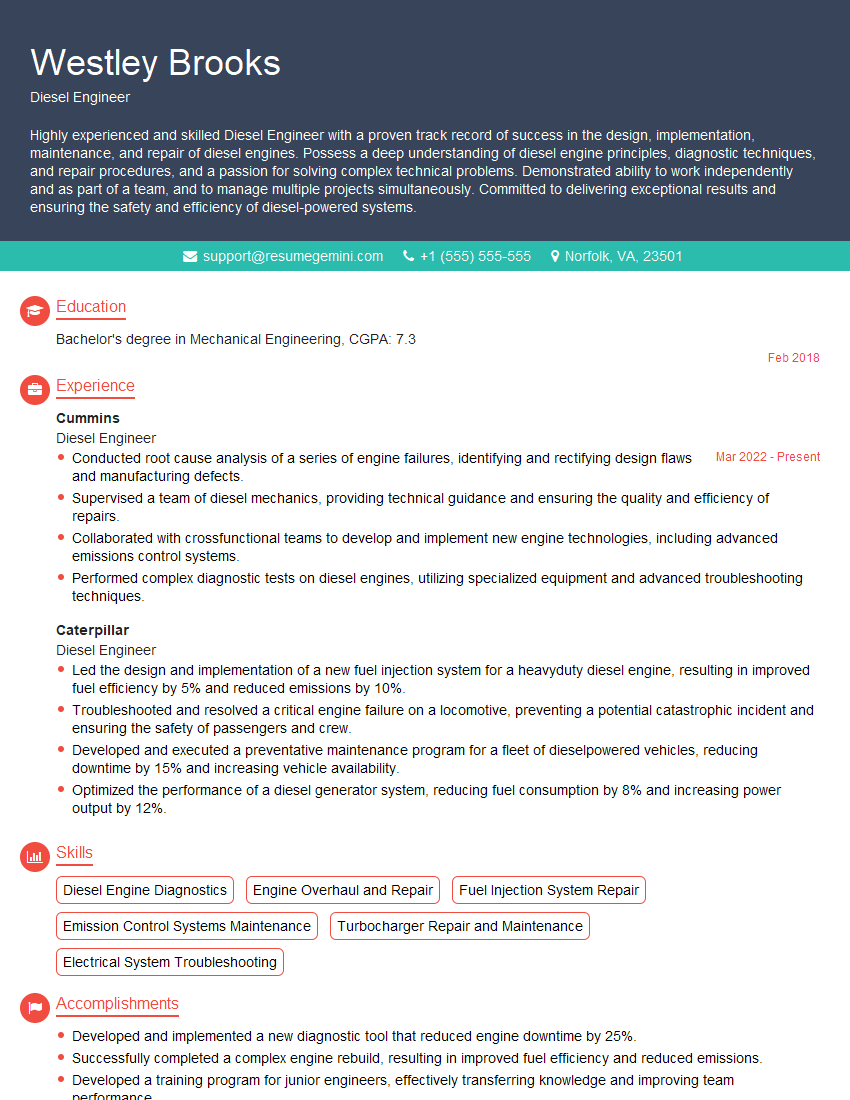

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diesel Engineer

1. Explain the working principle of a diesel engine?

A diesel engine is an internal combustion engine that operates on the diesel cycle. The diesel cycle consists of four strokes: intake, compression, power, and exhaust. During the intake stroke, air is drawn into the cylinder. During the compression stroke, the air is compressed to a high pressure and temperature. During the power stroke, fuel is injected into the cylinder and ignited by the heat of the compressed air. The burning fuel expands and drives the piston down, which in turn rotates the crankshaft. During the exhaust stroke, the exhaust gases are expelled from the cylinder.

2. What are the different types of diesel engines?

Automotive Diesel Engines

- Light-duty diesel engines are used in passenger cars and light trucks.

- Heavy-duty diesel engines are used in commercial trucks, buses, and construction equipment.

Industrial Diesel Engines

- Stationary diesel engines are used to generate electricity or power pumps and other equipment.

- Marine diesel engines are used to power ships and other marine vessels.

- Locomotive diesel engines are used to power locomotives.

3. What are the advantages and disadvantages of diesel engines?

Advantages

- Diesel engines are more efficient than gasoline engines, meaning they get more miles per gallon.

- Diesel engines produce less emissions than gasoline engines, which makes them better for the environment.

- Diesel engines are more durable than gasoline engines, which makes them last longer.

Disadvantages

- Diesel engines are more expensive to purchase than gasoline engines.

- Diesel engines can be louder than gasoline engines.

- Diesel engines require more maintenance than gasoline engines.

4. What are the key components of a diesel engine?

- Cylinder block

- Cylinder head

- Pistons

- Connecting rods

- Crankshaft

- Camshaft

- Valves

- Fuel injection system

- Turbocharger

- Aftercooler

5. What are the common problems that can occur with diesel engines?

- Fuel injection problems

- Turbocharger problems

- Aftercooler problems

- Cylinder head problems

- Piston problems

- Connecting rod problems

- Crankshaft problems

- Camshaft problems

- Valve problems

6. How do you troubleshoot a diesel engine?

To troubleshoot a diesel engine, you need to follow these steps:

- Gather information about the engine, including the make, model, and year.

- Inspect the engine for any visible problems, such as leaks, cracks, or broken parts.

- Check the engine’s fluids, including the oil, coolant, and fuel.

- Start the engine and listen for any unusual noises or vibrations.

- Use a diagnostic tool to scan the engine for any error codes.

- Based on the information you have gathered, diagnose the problem and make the necessary repairs.

7. What are the safety precautions that must be taken when working on a diesel engine?

- Always wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Never work on a diesel engine that is running.

- Always disconnect the battery before working on the engine.

- Be aware of the location of all hot surfaces and sharp edges.

- Never smoke or use open flames around a diesel engine.

- Always use proper tools and equipment when working on a diesel engine.

8. What are the latest trends in diesel engine technology?

- Common rail fuel injection

- Variable valve timing

- Turbocharging

- Aftercooling

- Diesel particulate filters

- Selective catalytic reduction

- Diesel oxidation catalysts

9. What are the challenges facing diesel engine manufacturers?

- Meeting increasingly stringent emissions regulations

- Improving fuel efficiency

- Reducing noise and vibration

- Developing new technologies to meet the needs of the market

- Competing with other engine technologies, such as gasoline engines and electric motors.

10. What are your career goals as a diesel engineer?

- To design and develop new diesel engine technologies that meet the needs of the market.

- To help diesel engine manufacturers meet increasingly stringent emissions regulations.

- To improve the fuel efficiency of diesel engines.

- To reduce noise and vibration in diesel engines.

- To develop new diesel engine applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diesel Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diesel Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diesel Engineers are responsible for the maintenance, repair, and operation of diesel engines and other related equipment. They ensure that engines are operating efficiently and safely, and they diagnose and repair any problems that may arise.Key job responsibilities include:

1. Maintenance and Repair

Diesel Engineers perform regular maintenance and repairs on diesel engines, including:

- Changing oil and filters

- Inspecting and adjusting valves

- Testing and repairing electrical systems

- Overhauling engines

2. Troubleshooting

Diesel Engineers troubleshoot and repair diesel engines that are not operating properly. They use their knowledge of diesel engine systems to identify the source of the problem and make the necessary repairs.

3. Operation

Diesel Engineers operate diesel engines in a variety of applications, including:

- Power generation

- Transportation

- Industrial equipment

4. Safety

Diesel Engineers must follow all safety regulations and procedures when working with diesel engines. They must be aware of the potential hazards of working with diesel fuel and exhaust, and they must take precautions to prevent accidents.

Interview Tips

Preparing for a Diesel Engineer interview can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:1. Research the company and the position

Before your interview, take some time to research the company you are applying to and the position you are interviewing for. This will help you understand the company’s culture and values, and it will also help you tailor your answers to the specific requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Diesel Engineer. Be prepared to discuss your work history, your technical skills, and your safety record.

4. Ask questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the company and the position, and to show the interviewer that you are interested and engaged.

5. Follow up

After the interview, send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and to reiterate your interest in the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Diesel Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.