Are you gearing up for a career in Diesel Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Diesel Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

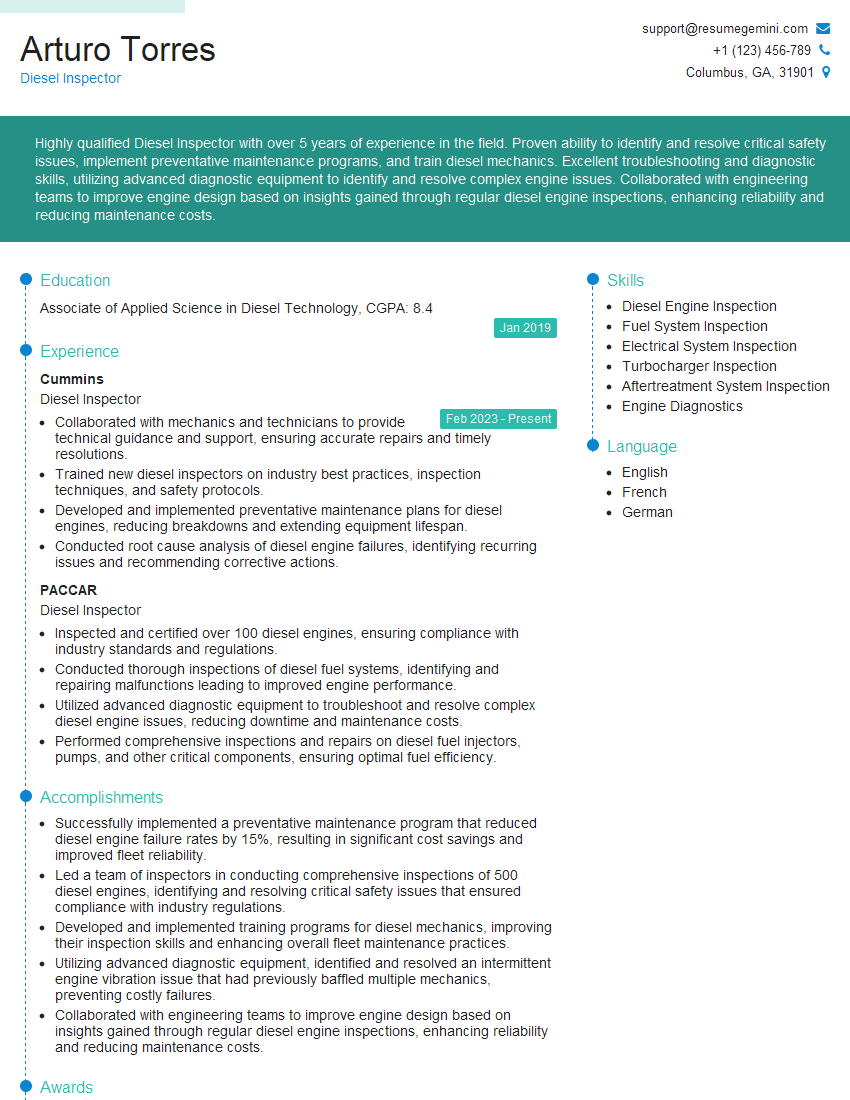

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diesel Inspector

1. Explain the process of conducting a diesel engine inspection?

The process of conducting a diesel engine inspection involves the following steps:

- Visual inspection: This involves examining the engine for any signs of damage, leaks, or corrosion. The inspector will also check the oil level and condition.

- Compression test: This test measures the compression pressure in each cylinder. A low compression pressure can indicate a worn piston, rings, or valves.

- Leakdown test: This test measures the amount of air that leaks out of the cylinders when the engine is at top dead center. A high leakdown rate can indicate a damaged piston, rings, or valves.

- Fuel system inspection: This involves checking the fuel lines, injectors, and fuel pump for any signs of damage or leaks. The inspector will also check the fuel pressure and flow rate.

- Electrical system inspection: This involves checking the battery, starter, alternator, and wiring for any signs of damage or corrosion. The inspector will also check the electrical system for proper operation.

2. What are the common problems associated with diesel engines?

Some of the common problems associated with diesel engines include:

- Fuel injection problems: These problems can be caused by a variety of factors, including clogged injectors, a faulty fuel pump, or a leaking fuel line.

- Compression problems: These problems can be caused by a worn piston, rings, or valves.

- Lubrication problems: These problems can be caused by a low oil level, a dirty oil filter, or a faulty oil pump.

- Cooling problems: These problems can be caused by a blocked radiator, a faulty water pump, or a leaking coolant hose.

- Electrical problems: These problems can be caused by a faulty battery, starter, alternator, or wiring.

3. What are the different types of diesel engine fuel injection systems?

The different types of diesel engine fuel injection systems include:

- Mechanical fuel injection: This type of system uses a mechanical pump to inject fuel into the cylinders. Mechanical fuel injection systems are typically found on older diesel engines.

- Electronic fuel injection: This type of system uses an electronic control unit (ECU) to control the fuel injection process. Electronic fuel injection systems are typically found on newer diesel engines.

- Common rail fuel injection: This type of system uses a common rail to supply fuel to the injectors. Common rail fuel injection systems are typically found on high-performance diesel engines.

4. What are the advantages and disadvantages of diesel engines?

Some of the advantages of diesel engines include:

- Fuel efficiency: Diesel engines are more fuel-efficient than gasoline engines.

- Power: Diesel engines produce more power than gasoline engines of the same size.

- Durability: Diesel engines are more durable than gasoline engines.

- Emissions: Diesel engines produce fewer emissions than gasoline engines.

Some of the disadvantages of diesel engines include:

- Cost: Diesel engines are more expensive than gasoline engines.

- Noise: Diesel engines are louder than gasoline engines.

- Cold weather performance: Diesel engines can be difficult to start in cold weather.

- Maintenance: Diesel engines require more maintenance than gasoline engines.

5. What are the different types of diesel engine turbochargers?

The different types of diesel engine turbochargers include:

- Wastegate turbochargers: These turbochargers use a wastegate to control the boost pressure.

- Variable geometry turbochargers: These turbochargers use variable geometry vanes to control the boost pressure.

- Twin-turbochargers: These turbochargers use two turbochargers to provide boost pressure.

6. What are the benefits of using a turbocharger on a diesel engine?

The benefits of using a turbocharger on a diesel engine include:

- Increased power: Turbochargers can increase the power output of a diesel engine by up to 50%.

- Improved fuel efficiency: Turbochargers can improve the fuel efficiency of a diesel engine by up to 20%.

- Reduced emissions: Turbochargers can help to reduce the emissions of a diesel engine by up to 30%.

7. What are the different types of diesel engine cooling systems?

The different types of diesel engine cooling systems include:

- Air-cooled systems: These systems use air to cool the engine.

- Water-cooled systems: These systems use water to cool the engine.

- Oil-cooled systems: These systems use oil to cool the engine.

8. What are the benefits of using an air compressor on a diesel engine?

The benefits of using an air compressor on a diesel engine include:

- Increased power: Air compressors can increase the power output of a diesel engine by up to 10%.

- Improved fuel efficiency: Air compressors can improve the fuel efficiency of a diesel engine by up to 5%.

- Reduced emissions: Air compressors can help to reduce the emissions of a diesel engine by up to 10%.

9. What are the different types of diesel engine exhaust systems?

The different types of diesel engine exhaust systems include:

- Mufflers: These devices reduce the noise of the exhaust.

- Catalytic converters: These devices convert harmful emissions into less harmful emissions.

- Diesel particulate filters: These devices remove soot from the exhaust.

10. What are the different types of diesel engine governors?

The different types of diesel engine governors include:

- Mechanical governors: These governors use a mechanical linkage to control the fuel injection.

- Electronic governors: These governors use an electronic control unit (ECU) to control the fuel injection.

- Hydraulic governors: These governors use hydraulic pressure to control the fuel injection.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diesel Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diesel Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diesel Inspectors are responsible for ensuring that diesel engines are operating safely and efficiently. They inspect, test, and maintain diesel engines, and they diagnose and repair any problems that may occur. Other key job responsibilities include:

1. Inspecting diesel engines for wear and tear

Diesel Inspectors visually inspect diesel engines for any signs of wear or tear. They check for leaks, cracks, and other damage. They also listen for any unusual noises that may indicate a problem.

- Use a variety of tools to inspect diesel engines, including gauges, meters, and microscopes.

- Keep detailed records of all inspections and repairs.

2. Testing diesel engines for performance

Diesel Inspectors test diesel engines to ensure that they are operating at peak performance. They measure engine speed, temperature, and pressure. They also check for emissions and other indicators of engine health.

- Use a variety of test equipment, including dynamometers, emissions analyzers, and pressure gauges.

- Interpret test results and make recommendations for repairs or adjustments.

3. Maintaining diesel engines

Diesel Inspectors perform routine maintenance on diesel engines to keep them running smoothly. They change oil, filters, and other fluids. They also adjust valves and other components as needed.

- Follow manufacturer’s recommended maintenance schedules.

- Use proper tools and techniques to perform maintenance tasks.

4. Diagnosing and repairing diesel engines

Diesel Inspectors diagnose and repair any problems that may occur with diesel engines. They use their knowledge of diesel engine mechanics to identify the source of the problem and make the necessary repairs.

- Use a variety of diagnostic tools, including engine analyzers, oscilloscopes, and multimeters.

- Repair or replace damaged components.

Interview Tips

Preparing for a Diesel Inspector interview can be daunting, but with the right approach, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you’re applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, in industry publications, or by talking to people who work there.

- Knowing about the company and position will help you answer questions intelligently and show that you’re genuinely interested in the job.

- For example, you might be asked about your experience with a particular type of diesel engine or about your knowledge of the latest industry regulations.

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” or “Why are you interested in this job?” It’s a good idea to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- When answering questions, be sure to highlight your skills and experience that are relevant to the job.

- For example, if you’re asked about your experience with diesel engines, you might mention a specific project that you worked on where you successfully diagnosed and repaired a complex problem.

3. Be prepared to talk about your safety record

Safety is of paramount importance in the diesel industry. In your interview, you’re likely to be asked about your safety record and your knowledge of safety procedures. Be prepared to discuss your experience with safety protocols and any steps you’ve taken to improve safety in the workplace.

- For example, you might mention a time when you identified a potential hazard and took steps to mitigate the risk.

- You might also be asked about your knowledge of specific safety regulations, such as OSHA regulations.

4. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview and arrive on time. This shows that you’re serious about the job and that you respect the interviewer’s time.

- When choosing what to wear, consider the company’s culture and the specific position you’re applying for.

- For example, if you’re applying for a job in a formal setting, you might wear a suit or dress. If you’re applying for a job in a more casual setting, you might wear khakis and a button-down shirt.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Diesel Inspector, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Diesel Inspector positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.