Feeling lost in a sea of interview questions? Landed that dream interview for Diesel Maintenance Electrician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Diesel Maintenance Electrician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

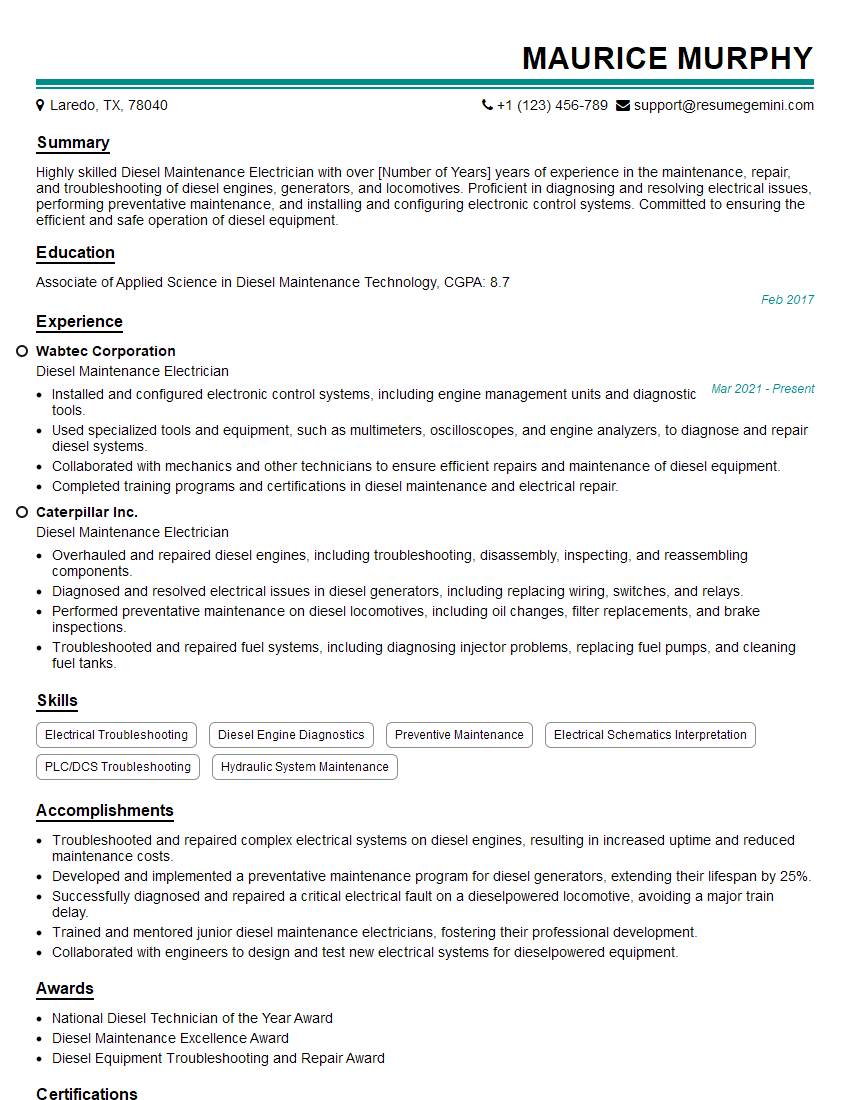

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diesel Maintenance Electrician

1. Explain the process of troubleshooting a diesel engine that is not starting?

Answer:

- Check for fuel: Verify if there is fuel in the tank and that it is flowing properly to the engine.

- Check for air: Ensure that the air filter is clean and that there are no blockages in the intake system.

- Check for compression: Perform a compression test to determine if the engine has sufficient compression to start.

- Check for spark: If the engine is equipped with spark plugs, check for spark at each plug using a spark tester.

- Check for electrical power: Verify that the battery is providing adequate voltage and that all electrical connections are secure.

2. Describe the different types of fuel injection systems used in diesel engines?

Mechanical Injection:

- Uses a mechanical pump to inject fuel into the cylinders at high pressure.

- Components include a fuel pump, injectors, and fuel lines.

Electronic Injection:

- Controls fuel injection using electronic components, such as sensors, controllers, and actuators.

- Allows for precise control of injection timing, duration, and quantity.

Common Rail Injection:

- Utilizes a common pressure rail to supply fuel to the injectors.

- Offers high injection pressures and precise fuel delivery.

3. How do you diagnose and repair electrical faults in diesel engines?

Answer:

- Visual inspection: Check for loose connections, damaged wires, or corrosion.

- Electrical testing: Use a multimeter to measure voltage, resistance, and continuity.

- Component testing: Test individual components, such as sensors, switches, and actuators.

- Circuit tracing: Trace electrical circuits to identify faults and open or shorted connections.

4. Explain the importance of proper maintenance for diesel engines?

Answer:

- Reduced downtime: Regular maintenance helps prevent unscheduled engine failures.

- Increased efficiency: Clean and well-maintained engines operate more efficiently.

- Extended lifespan: Proper maintenance can significantly increase the lifespan of the engine.

- Improved emissions: Well-maintained engines produce lower emissions.

5. Describe the different types of lubrication systems used in diesel engines?

Splash Lubrication:

- Uses a crankshaft to splash oil onto the moving parts.

- Suitable for low-speed engines and small engines.

Pressure Lubrication:

- Utilizes an oil pump to force oil under pressure to the engine’s moving parts.

- Provides more consistent and effective lubrication.

Full-Flow Lubrication:

- All of the oil pumped by the oil pump passes through the oil filter before being distributed to the engine.

- Ensures maximum filtration and lubrication.

6. How do you service a diesel engine’s cooling system?

Answer:

- Drain and refill coolant: Remove the old coolant and replace it with fresh coolant.

- Inspect and clean: Check the radiator, hoses, and water pump for leaks, damage, or blockages.

- Pressure test: Perform a pressure test to identify leaks in the cooling system.

- Replace thermostat: If the thermostat is faulty, replace it with a new one.

7. Explain the role of turbochargers in diesel engines?

Answer:

- Increases the engine’s air intake by using exhaust gases to spin a turbine.

- Increases engine power and torque.

- Improves fuel efficiency by increasing the density of the air entering the engine.

8. Describe the key components of a diesel engine’s fuel system?

Fuel Tank and Fuel Lines:

- Store and transport fuel to the engine.

Fuel Pump:

- Pressurizes and delivers fuel to the injectors.

Fuel Filter:

- Removes contaminants from the fuel.

Fuel Injectors:

- Injects the correct amount of fuel into the cylinders at the appropriate time.

9. How do you measure and adjust valve clearances on a diesel engine?

Answer:

- Use a feeler gauge: Insert a feeler gauge between the valve stem and the rocker arm to measure the clearance.

- Adjust using shims: Add or remove shims to adjust the clearance to the specified value.

- Retighten: Retighten the rocker arm nuts to the correct torque.

10. Describe the safety precautions that must be taken when working on diesel engines?

Answer:

- Wear appropriate PPE: Safety glasses, gloves, and coveralls.

- Disconnect the battery: Prevent electrical accidents.

- Allow the engine to cool: Avoid burns or contact with hot components.

- Use proper lifting techniques: Handle heavy parts safely.

- Be aware of hazardous fluids: Fuel, coolant, and oil can be harmful.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diesel Maintenance Electrician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diesel Maintenance Electrician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diesel Maintenance Electricians are responsible for maintaining and repairing diesel engines and related electrical systems. Key job responsibilities include:

1. Troubleshooting and repairing electrical systems

This involves identifying the source of electrical faults and making repairs to restore functionality.

- Using diagnostic tools to locate electrical faults

- Repairing or replacing faulty electrical components

2. Maintaining electrical systems

This includes performing regular inspections, cleaning, and lubrication to ensure optimal performance.

- Inspecting electrical systems for wear and tear

- Cleaning and lubricating electrical components

- Testing electrical systems to ensure proper operation

3. Installing electrical systems

This involves installing new electrical systems or modifying existing systems to meet specific requirements.

- Reading and interpreting electrical schematics

- Installing electrical components according to specifications

- Testing electrical systems to ensure proper operation

4. Working with diesel engines

This involves understanding the operation of diesel engines and performing maintenance and repair tasks as needed.

- Performing routine maintenance on diesel engines

- Diagnosing and repairing diesel engine problems

- Overhauling diesel engines as necessary

Interview Tips

Preparing for an interview for a Diesel Maintenance Electrician position requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the company and the position

Researching the company and the specific position you’re applying for will give you a better understanding of the company’s culture, values, and what they’re looking for in a candidate.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on the latest trends

2. Practice your answers to common interview questions

Practice answering common interview questions related to your technical skills, experience, and qualifications. This will help you feel more confident and prepared during the interview.

- Prepare answers to questions about your experience with diesel engines and electrical systems

- Practice answering questions about your troubleshooting and problem-solving skills

3. Highlight your relevant skills and experience

Tailor your resume and cover letter to highlight your skills and experience that are most relevant to the position you’re applying for. Use specific examples to demonstrate your abilities.

- Quantify your accomplishments whenever possible to show the impact of your work

- Use action verbs to describe your skills and experience

4. Be enthusiastic and professional

During the interview, be enthusiastic about the position and the company. Show that you’re passionate about your work and that you’re eager to learn and grow.

- Make eye contact and speak clearly

- Dress professionally and arrive on time for your interview

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Diesel Maintenance Electrician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!