Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Digester position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

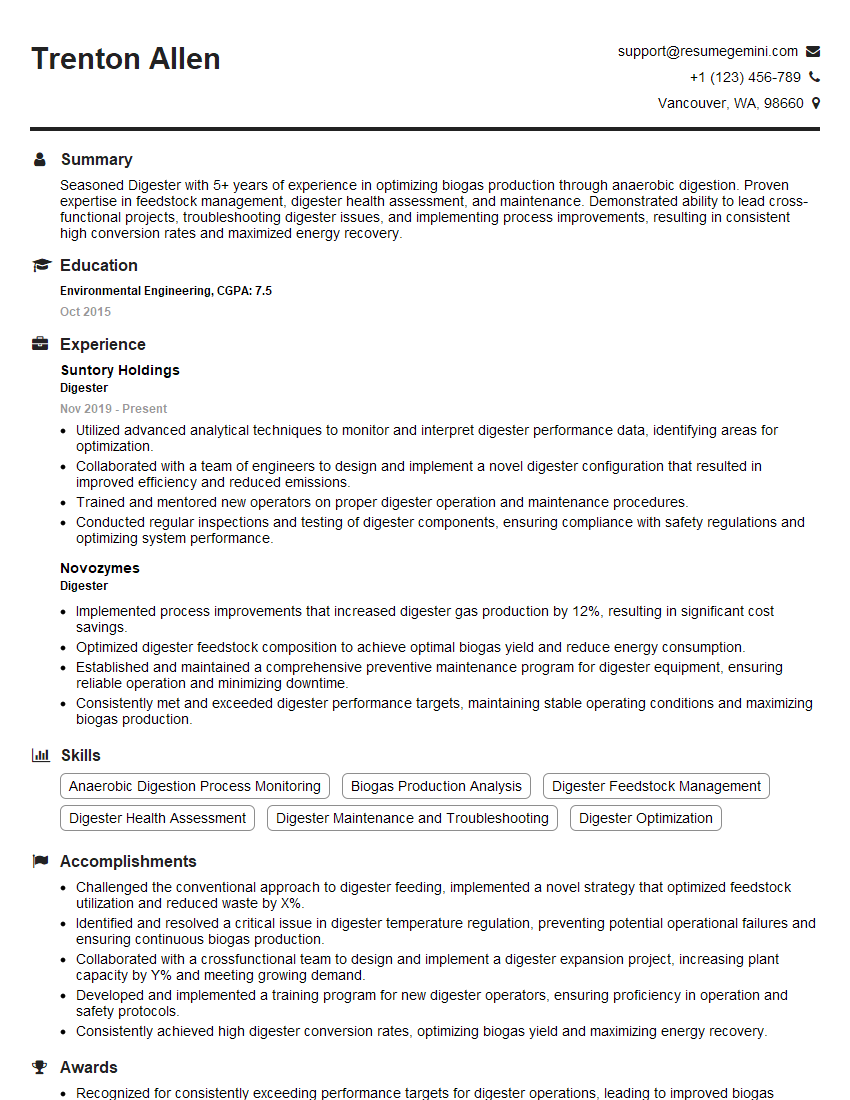

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Digester

1. What are the different types of digesters used in wastewater treatment?

Various types of digesters employed in wastewater treatment include:

- Anaerobic Digesters: These digesters decompose organic matter in the absence of oxygen, producing biogas (methane and carbon dioxide).

- Aerobic Digesters: These digesters utilize oxygen to break down organic matter, leading to the production of carbon dioxide and water.

2. What are the key parameters to monitor and control in an anaerobic digester?

Temperature

- Monitoring and maintaining optimal temperature levels are critical for the efficient operation of the digester and the health of the microbial community.

- Methane-producing bacteria thrive within a specific temperature range, typically between 30-38°C (86-100°F).

pH

- Monitoring and controlling pH levels within the recommended range (6.8-7.2) is crucial.

- High or low pH levels can inhibit microbial activity and reduce biogas production.

Organic Loading Rate (OLR)

- OLR is the amount of organic matter (measured as Chemical Oxygen Demand or COD) added to the digester per unit volume per day.

- Balancing the OLR ensures that the digester can effectively break down the influent organic matter without overloading.

3. How do you calculate the retention time in a digester?

Retention time (RT) refers to the average time that organic matter remains within the digester.

Formula: RT = Volume of digester / Volumetric flow rate

- Volume of digester: Expressed in cubic meters or gallons.

- Volumetric flow rate: Flow rate of the influent or effluent stream, typically measured in cubic meters per day or gallons per day.

4. What are the benefits of using a digester in wastewater treatment?

- Biogas Production: Anaerobic digesters produce biogas, a renewable energy source that can be used to generate electricity or heat.

- Sludge Reduction: Digestion significantly reduces the volume of sludge produced in the treatment process, reducing disposal costs.

- Pathogen Reduction: The high temperatures and extended retention times in digesters effectively kill pathogens, making the treated effluent safer.

- Odor Reduction: Anaerobic digestion minimizes odors associated with wastewater treatment, improving community acceptance.

5. What are the challenges associated with operating and maintaining a digester?

- Process Upsets: Changes in influent characteristics or operational parameters can lead to process upsets, affecting biogas production and digestate quality.

- Corrosion: Anaerobic digesters can be susceptible to corrosion due to the presence of hydrogen sulfide and other corrosive gases.

- Foaming: Excessive foaming can occur in digesters, causing operational issues and reducing biogas production.

- Sludge Settling: Poor settling of digested sludge can lead to carryover of solids in the effluent, compromising treatment efficiency.

6. How do you troubleshoot a digester that is not producing sufficient biogas?

- Check Temperature: Ensure the digester is operating within the optimal temperature range for the microbial community.

- Verify pH: Measure and adjust pH levels to maintain a suitable range for microbial activity.

- Assess OLR: Evaluate the OLR and adjust the influent flow or organic content to ensure the digester is not overloaded or underfed.

- Examine Mixing: Proper mixing ensures contact between microorganisms and organic matter. Check and optimize the mixing system.

- Monitor Feedstock: Assess the characteristics of the influent feedstock and identify any changes that may affect biogas production.

7. What is the role of alkalinity in an anaerobic digester?

- Alkalinity refers to the buffering capacity of the digester contents to neutralize acids produced during the digestion process.

- Sufficient alkalinity levels are essential to maintain a stable pH and prevent digester upset.

- Sources of alkalinity include bicarbonate, carbonate, and hydroxide ions, which can be added or adjusted as needed.

8. How do you design a digester to optimize biogas production?

- Volume: Determine the digester volume based on the required retention time and influent characteristics.

- Mixing: Implement an effective mixing system to ensure thorough contact between microorganisms and organic matter.

- Temperature Control: Design the digester with insulation and heating systems to maintain the optimal temperature range.

- Gas Collection: Provision for efficient gas collection and removal is crucial to maximize biogas yield.

- Feedstock Pretreatment: Consider pretreatment methods to enhance the biodegradability of the feedstock and increase biogas production.

9. What are the safety considerations when working with anaerobic digesters?

- Confined Space: Digesters are enclosed spaces with limited ventilation. Proper precautions must be taken to ensure adequate ventilation and safe entry.

- Biogas Hazards: Biogas is flammable and can accumulate in digester headspaces. Gas detection and ventilation systems are essential.

- Hydrogen Sulfide: Anaerobic digestion produces hydrogen sulfide gas, which is toxic and can cause health risks. Proper ventilation and respiratory protection are necessary.

- Pathogens: Digested sludge may contain pathogens. Appropriate precautions for safe handling and disposal must be followed.

10. What are the emerging trends and advancements in digester technology?

- Co-Digestion: Co-digesting wastewater sludge with other organic waste streams, such as food waste or agricultural residues, enhances biogas production and resource utilization.

- Two-Stage Digestion: Implementing a two-stage digestion process can improve sludge stabilization and biogas yield.

- Membrane-Assisted Digestion: Integrating membrane technology allows for the separation of biogas and digestate, improving gas quality and reducing energy consumption.

- Microbial Community Monitoring: Advanced techniques for monitoring the microbial community in digesters enable better process control and optimization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Digester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Digester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Digester is responsible for monitoring and controlling the digestion process, maintaining the digester system and ensuring the efficient production of biogas.

1. Monitor and Control Digestion Process

The primary responsibility of a Digester is to closely monitor and control the digestion process by maintaining optimal conditions for biogas production. This involves:

- Monitoring and adjusting the temperature, pH levels, and nutrient content of the digester feedstock to ensure optimal conditions for bacterial growth and biogas production.

- Controlling the flow rate and retention time of the feedstock to optimize the digestion process and maximize biogas yield.

- Troubleshooting and resolving any issues that may arise during the digestion process to maintain efficient operation and prevent downtime.

2. Maintain Digester System

Digesters also play a crucial role in maintaining the digester system to ensure its proper functioning and longevity. Key responsibilities include:

- Regularly inspecting and cleaning the digester system to remove any blockages, leaks, or corrosion.

- Performing preventive maintenance tasks, such as replacing filters, gaskets, and membranes, to ensure the system operates at peak performance.

- Monitoring and calibrating the digester system’s instrumentation to ensure accurate readings and optimal control.

3. Optimize Biogas Production

Digesters are tasked with optimizing biogas production by implementing various strategies and measures. This involves:

- Selecting and blending feedstocks to achieve the desired biogas yield and composition.

- Employing techniques such as co-digestion and pre-treatment to enhance the digestibility of feedstock and increase biogas production.

- Monitoring and analyzing biogas quality parameters, such as methane content and impurities, to ensure it meets specific requirements.

4. Ensure Health and Safety

Digesters must prioritize health and safety measures to minimize risks associated with biogas production. Responsibilities include:

- Following established safety protocols and procedures when handling biogas and other hazardous materials.

- Conducting regular safety inspections and monitoring systems to identify and mitigate potential hazards.

- Maintaining a clean and organized work environment to prevent accidents and ensure the well-being of employees.

Interview Tips

Preparing for a Digester interview requires thorough research and a solid understanding of the key job responsibilities.

1. Research the Company and Industry

Before the interview, take the time to thoroughly research the company and the biogas industry. Familiarize yourself with the company’s mission, values, and recent developments. Additionally, stay updated on industry trends and best practices to demonstrate your knowledge and interest.

2. Highlight Relevant Experience and Skills

Emphasize your relevant experience and skills that align with the key job responsibilities of a Digester. Showcase your expertise in monitoring and controlling digestion processes, maintaining digester systems, and optimizing biogas production.

3. Prepare Industry-Specific Questions

Preparing industry-specific questions demonstrates your genuine interest and understanding of the field. Ask questions about the company’s approach to biogas production, their strategies for optimizing digestion processes, and their commitment to sustainability.

4. Showcase Problem-Solving Abilities

Interviewers are keen on assessing your problem-solving abilities. Prepare examples from your previous work experience where you successfully identified and resolved issues related to digestion processes or digester system maintenance.

5. Practice Active Listening

During the interview, practice active listening by paying close attention to the interviewer’s questions and responses. Ask clarifying questions to demonstrate your engagement and understanding of their perspectives.

6. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Express your passion for biogas production and your desire to contribute to the company’s goals. Remember to dress professionally and maintain a polite and respectful demeanor.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Digester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.