Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Digital Proofing and Platemaker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

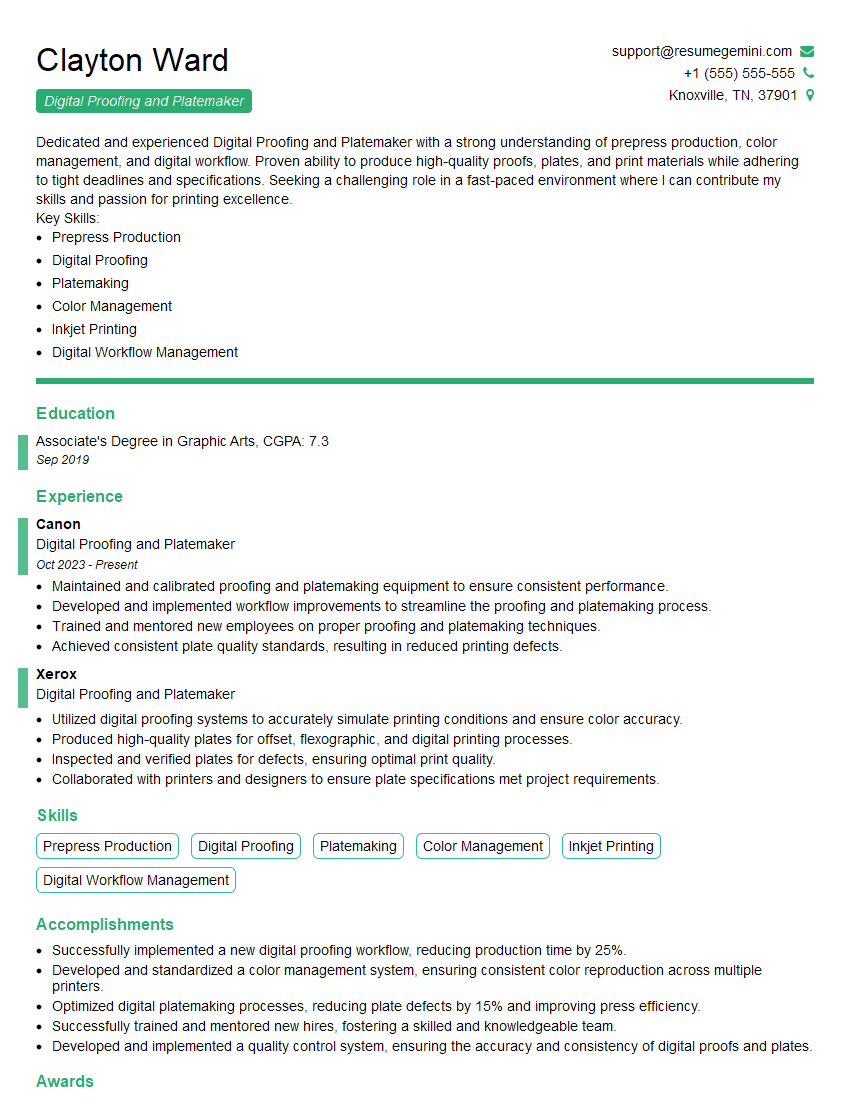

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Digital Proofing and Platemaker

1. What preflight checks do you perform before sending files to print?

- Check for missing fonts and images.

- Verify the color space and resolution.

- Inspect the layout and margins.

- Ensure that the file format is compatible with the printing press.

- Review the output for errors.

2. How do you manage color accuracy throughout the digital proofing process?

Color Calibration and Profiling

- Calibrate and profile monitors and printers regularly.

- Use a spectrophotometer to measure and adjust color values.

Color Standards and Communication

- Adhere to industry color standards (e.g., ISO, G7).

- Communicate color specifications clearly with designers and printers.

3. Explain the process of creating a digital proof.

- Receive the print-ready file.

- Convert the file to a digital format (e.g., PDF).

- Apply color profiles.

- Proof the file on a calibrated monitor.

- Make any necessary corrections.

- Generate a high-resolution digital proof.

4. How do you troubleshoot common problems encountered during digital proofing?

- Color accuracy issues: Check calibration, color profiles, and printer settings.

- Image resolution problems: Ensure the file has sufficient resolution for the desired print quality.

- File format errors: Convert the file to a compatible format.

- Layout and margin errors: Adjust the file settings and proof again.

- Printer hardware malfunctions: Contact the printer manufacturer for support.

5. What quality control measures do you implement to ensure the accuracy of platemaking?

- Prepress file checking: Inspect the file for errors and make corrections as needed.

- Plate inspection: Examine the plates for scratches, defects, or misalignments.

- Printing press setup: Verify the press settings and make adjustments to optimize print quality.

- Proofing: Generate a physical proof to verify color accuracy and registration.

- On-press monitoring: Monitor the printing process and make adjustments as necessary.

6. Describe the different types of platemaking processes and their advantages and disadvantages.

1. Thermal Platemaking

- Advantages: Fast and cost-effective.

- Disadvantages: Limited tonal range and durability.

2. CtP (Computer-to-Plate)

- Advantages: High resolution, wide tonal range, and long durability.

- Disadvantages: More expensive and time-consuming.

7. How do you handle press adjustments to correct common printing problems?

Registration Errors

- Adjust the plate position or press settings.

Color Imbalance

- Check the ink levels and adjust the ink fountain.

- Calibrate the press.

8. What safety precautions should be taken when operating a platemaking machine?

- Wear appropriate safety gear (e.g., gloves, goggles).

- Follow the manufacturer’s operating instructions.

- Keep the work area clean and organized.

- Be aware of potential hazards (e.g., chemical spills, sharp edges).

- Report any accidents or emergencies immediately.

9. How do you keep up with advancements in digital proofing and platemaking technologies?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Network with other professionals in the field.

- Explore new technologies and techniques.

- Seek training and certification opportunities.

10. Describe your experience in working with different press types and paper stocks.

Press Types

- Offset: Flatbed press with plates.

- Digital: Uses toner or ink to print directly onto paper.

- Flexographic: Uses flexible plates to print on flexible materials.

Paper Stocks

- Uncoated: Absorbent, provides a matte finish.

- Coated: Has a smooth surface, provides a glossy finish.

- Specialty: Includes textured, metallic, and translucent papers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Digital Proofing and Platemaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Digital Proofing and Platemaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Digital Proofing and Platemaker is responsible for preparing and maintaining printing plates used in offset printing processes. They ensure that the plates accurately reproduce the desired image or text onto the printing surface, producing high-quality printed materials. Key responsibilities include:

1. Digital Proofing

Proofread and review digital proofs to ensure they meet the customer’s specifications and are free from errors, such as color inaccuracies or missing elements.

2. Platemaking

Create and process printing plates using computer-to-plate (CTP) technology, ensuring that the plates adhere to the print job requirements and industry standards.

3. Plate Maintenance

Maintain, clean, and inspect printing plates throughout the production process to ensure optimal performance and longevity.

4. Quality Control

Monitor and evaluate the quality of printed materials produced from the plates created, identifying and correcting any issues that arise.

Interview Tips

To ace the interview for a Digital Proofing and Platemaker position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and products/services. Understand the specific requirements of the role and how your skills and experience align with them.

2. Highlight Technical Proficiency

Emphasize your expertise in digital proofing and platemaking techniques, including CTP technology. Provide examples of your quality control measures and ability to troubleshoot production issues.

3. Showcase Problem-Solving Abilities

Describe situations where you identified and resolved printing problems effectively. Explain your analytical and critical thinking skills, as well as your attention to detail.

4. Prepare for Technical Questions

Review common technical questions related to digital proofing and platemaking, such as CTP process, color management, and plate maintenance best practices.

5. Demonstrate Teamwork and Communication Skills

Highlight your ability to work effectively in a team environment and communicate clearly with both technical and non-technical professionals.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Digital Proofing and Platemaker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Digital Proofing and Platemaker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.