Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dimension Mill Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

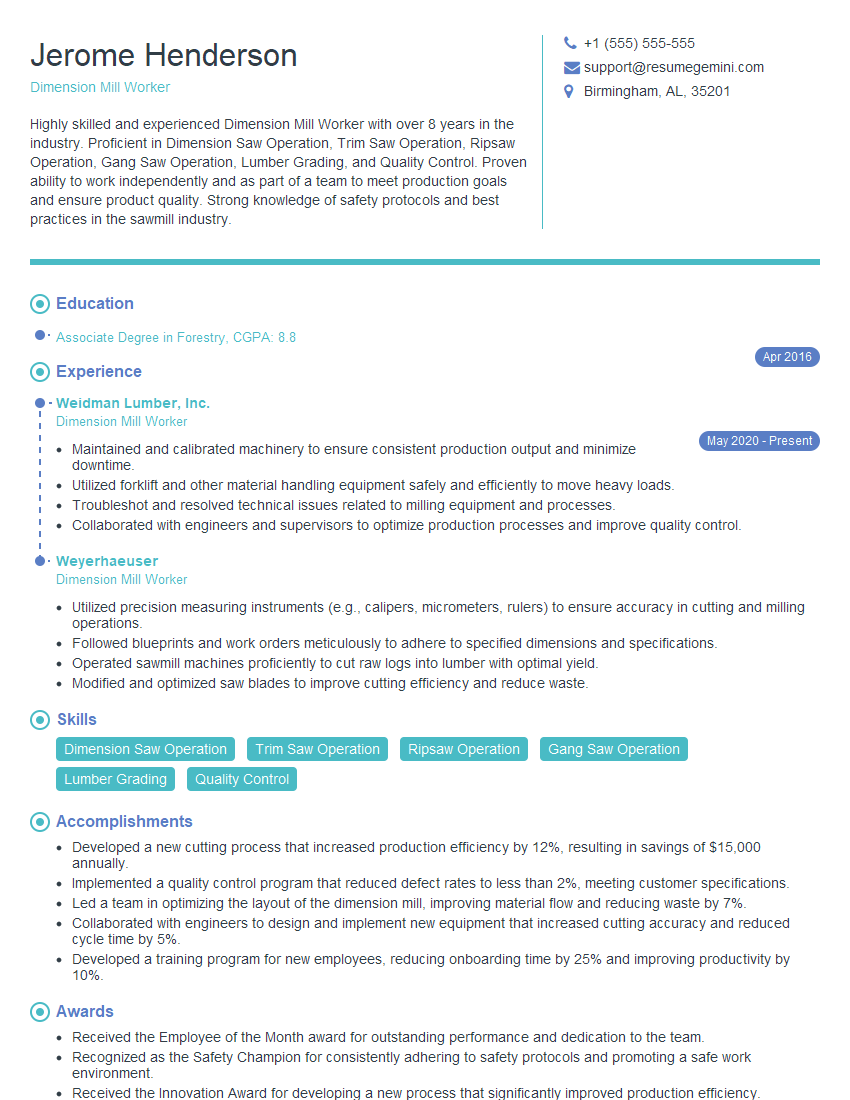

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dimension Mill Worker

1. What are the different types of dimension milling machines?

Various types of dimension milling machines are used in industries, such as:

- Gang Rip Saw: Used for initial breakdown of logs

- Resaw: Break down cants or flitches into individual boards

- Edger: Process flitches/cants into boards with a square edge

- Trimmer: Cuts boards to desired length

2. How do you ensure the accuracy of the cut dimensions?

Calibrating the Saw

- Use a calibration block to set the saw blade height and alignment.

- Check the saw blade run-out to ensure it is within tolerance.

Maintaining Sharp Blades

- Replace dull or damaged saw blades promptly to maintain cutting accuracy.

- Consider using carbide-tipped blades for longer blade life and reduced cutting deviations.

3. How do you troubleshoot common problems with dimension milling machines?

Common issues include:

- Misaligned Saw Blade: Recalibrate the blade using a calibration block.

- Dull Blades: Replace the blade with a sharp one.

- Incorrect Feed Rate: Adjust the feed rate to match the material being cut.

- Machine Malfunction: Check for any electrical or mechanical issues and contact maintenance personnel.

4. What safety precautions should be taken when operating a dimension milling machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves.

- Ensure the machine is properly grounded and guarded.

- Never operate the machine with loose clothing or jewelry.

- Keep hands clear of the cutting area and use proper push sticks or feather boards.

- Be aware of the location of the emergency stop button.

5. How do you calculate the board footage of lumber?

The formula for board footage is: Board Feet = Length (ft.) x Width (in.) x Thickness (in.) / 12

- Measure the length, width, and thickness of the lumber in inches.

- Multiply the three measurements together.

- Divide the result by 12 to convert the answer to board feet.

6. What are the different grades of lumber used for dimension milling?

Lumber grades commonly used for dimension milling include:

- Select Structural: High-quality lumber with few knots or defects, used for structural applications.

- No. 1 Structural: Similar to Select Structural, but allows for some small knots and defects.

- No. 2 Structural: Suitable for general construction, allows for larger knots and some warping.

- Utility Grade: Lower-grade lumber with more imperfections, used for projects where appearance is not critical.

7. How do you maintain and clean a dimension milling machine?

- Daily Cleaning: Remove sawdust and debris from the machine using a brush or compressed air.

- Weekly Maintenance: Lubricate moving parts and check for loose bolts or screws.

- Monthly Maintenance: Clean the electrical components and inspect the saw blade for damage.

- Annual Maintenance: Have the machine serviced by a qualified technician for a thorough inspection and any necessary repairs.

8. What are the common types of defects that can occur during dimension milling?

- Saw Marks: Uneven or rough surfaces caused by incorrect saw blade alignment or dull blades.

- Warping: Boards that have twisted or bent due to uneven drying or improper storage.

- Knots: Natural imperfections in the wood that can affect the strength and appearance of the lumber.

- Splits: Cracks or separations in the wood that can occur during the milling process.

9. How do you handle situations where the lumber is not of the specified quality or dimensions?

- Inspect the Lumber: Check the lumber carefully before using it to identify any defects or deviations from specifications.

- Contact the Supplier: Inform the supplier about the issue and request a replacement or credit.

- Adjust the Cutting Parameters: If possible, adjust the cutting parameters on the dimension milling machine to accommodate the variations in the lumber.

- Document the Issue: Keep a record of the defective lumber and any communication with the supplier.

10. What are the key performance indicators (KPIs) used to evaluate the efficiency of a dimension milling operation?

- Production Output: Total volume of lumber processed within a given time frame.

- Accuracy: Percentage of products that meet the specified dimensions.

- Quality: Percentage of products that are free from defects.

- Machine Utilization: Amount of time the machine is in operation compared to idle time.

- Waste Generation: Amount of unusable lumber produced during the milling process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dimension Mill Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dimension Mill Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Dimension Mill Worker, you will perform a variety of tasks related to the production of dimension lumber. Your key responsibilities will include:

1. Operating and maintaining sawmill equipment

You will be responsible for operating and maintaining a variety of sawmill equipment, including saws, edgers, and trimmers. You must be able to troubleshoot and repair mechanical problems, and maintain a safe and efficient work environment.

- Operate saws to cut logs into lumber

- Edge lumber to remove bark and defects

- Trim lumber to specified lengths

- Maintain and repair sawmill equipment

2. Inspecting lumber for quality

You will be responsible for inspecting lumber for quality defects, such as knots, cracks, and splits. You must be able to identify and grade lumber according to industry standards.

- Inspect lumber for defects

- Grade lumber according to industry standards

- Reject lumber that does not meet quality standards

3. Stacking and loading lumber

You will be responsible for stacking and loading lumber onto trucks or rail cars. You must be able to work safely and efficiently in a fast-paced environment.

- Stack lumber on pallets

- Load pallets onto trucks or rail cars

- Secure lumber for transport

4. Other duties as assigned

In addition to the above responsibilities, you may also be required to perform other duties as assigned by your supervisor. These duties may include:

- Cleaning and maintaining the sawmill

- Assisting with other production tasks

- Following all safety procedures

Interview Tips

To ace your interview for a Dimension Mill Worker position, you should be prepared to discuss your experience and skills in the following areas:

1. Sawmill operations

You should be familiar with the operation and maintenance of sawmill equipment, including saws, edgers, and trimmers. You should also be able to troubleshoot and repair mechanical problems.

- Describe your experience operating and maintaining sawmill equipment.

- Provide examples of how you have troubleshoot and repaired mechanical problems.

2. Lumber grading

You should be able to identify and grade lumber according to industry standards. You should also be familiar with the different types of lumber defects and how they affect the quality of the lumber.

- Describe your experience grading lumber.

- Provide examples of how you have identified and graded lumber defects.

3. Physical fitness

Dimension Mill Workers must be physically fit to perform the duties of the job, which may include lifting heavy lumber and working in a fast-paced environment. You should be able to work safely and efficiently for long periods of time.

- Describe your physical fitness level.

- Provide examples of how you have performed physically demanding tasks in the past.

4. Safety

Safety is a top priority in the sawmill industry. You should be familiar with all safety procedures and be committed to working safely at all times.

- Describe your understanding of sawmill safety procedures.

- Provide examples of how you have followed safety procedures in the past.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dimension Mill Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!