Feeling lost in a sea of interview questions? Landed that dream interview for Dimpling Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dimpling Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

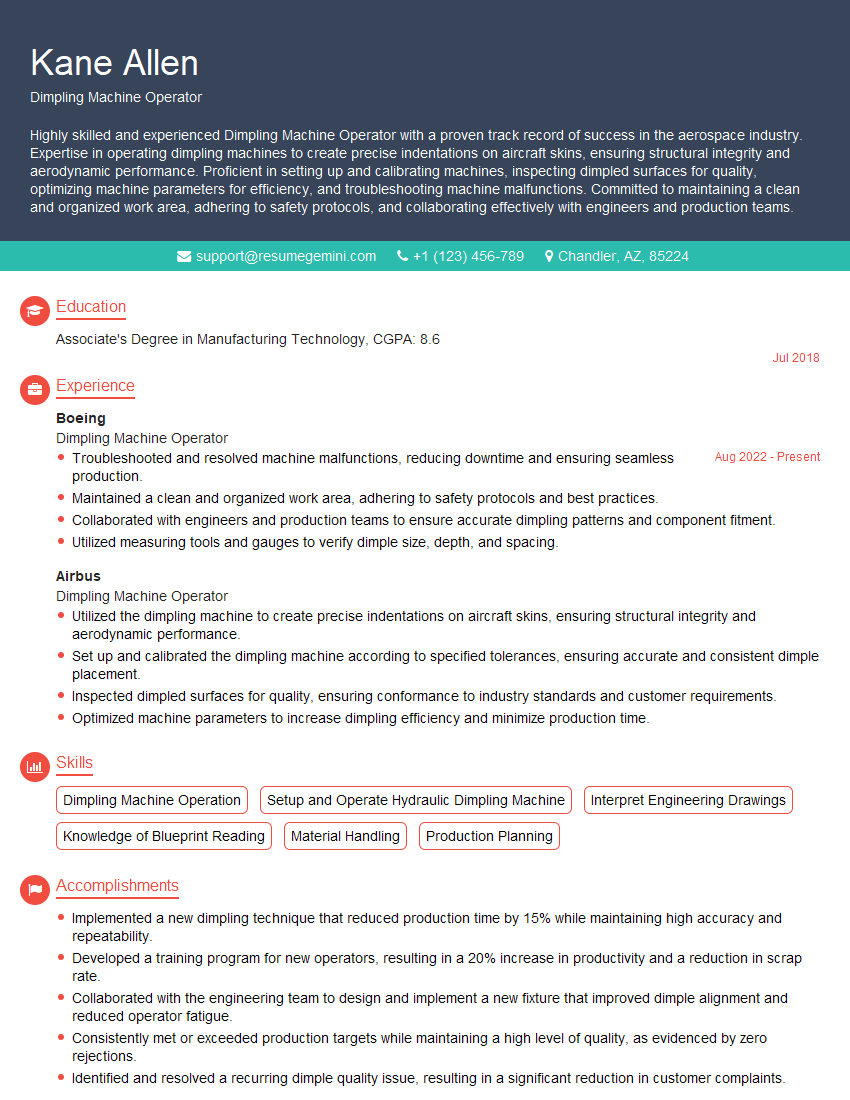

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dimpling Machine Operator

1. What are the key responsibilities of a Dimpling Machine Operator?

- Operate and monitor dimpling machines to create dimples in aircraft panels and other sheet metal components.

- Set up and adjust the machine according to specifications, ensuring accurate and consistent dimple formation.

- Inspect dimples for quality, adhering to industry standards and customer requirements.

- Maintain the dimpling machine and work area in a clean and organized condition.

- Follow safety protocols and wear appropriate personal protective equipment (PPE).

2. Describe the different types of dimpling machines and their applications.

Pneumatic Dimpling Machines

- Operate using compressed air to create dimples.

- Suitable for high-volume production environments.

- Can handle various materials, including aluminum, steel, and titanium.

Hydraulic Dimpling Machines

- Use hydraulic pressure to create dimples.

- Provide precise and consistent dimple formation.

- Well-suited for intricate dimpling patterns and specialized applications.

Manual Dimpling Machines

- Operated by hand using a press.

- Suitable for small-scale production or prototyping.

- Require more operator skill and can be slower than automated machines.

3. What are the critical process parameters to consider when dimpling sheet metal?

- Dimpling force: Controls the depth and diameter of the dimple.

- Dwell time: The amount of time the machine holds the dimple under pressure.

- Tool size and shape: Determines the size and shape of the dimple.

- Material properties: The thickness, hardness, and ductility of the sheet metal can affect dimpling results.

- Machine settings: Proper calibration and maintenance ensure consistent dimple formation.

4. How do you troubleshoot common dimpling defects?

- Shallow or incomplete dimples: Insufficient force, short dwell time, or worn tools.

- Oversized or irregular dimples: Excessive force, long dwell time, or dull tools.

- Tears or cracks: Too much force, improper tool size, or weak material.

- Misalignment: Incorrect machine setup or workpiece positioning.

- Tool chatter: Loose tools, excessive vibration, or poor machine maintenance.

5. What preventative maintenance tasks are performed on dimpling machines?

- Regular cleaning and lubrication: Remove debris and apply lubricants to moving parts.

- Tool inspection and sharpening: Check tools for wear or damage, and sharpen as needed.

- Pressure calibration: Ensure accurate dimpling force.

- Safety checks: Inspect safety guards, electrical connections, and hydraulic lines.

- Machine alignment: Verify that the machine is properly aligned for precise dimple formation.

6. How do you ensure the quality of dimples produced by the dimpling machine?

- Visual inspection: Check for proper dimple formation, including depth, diameter, and shape.

- Dimensional measurement: Use calibrated measuring tools to verify dimple dimensions meet specifications.

- NDT testing: Conduct non-destructive testing methods, such as dye penetrant inspection or ultrasonic testing, to detect any cracks or defects.

- Statistical process control: Monitor dimpling parameters and track quality results to identify areas for improvement.

- Regular machine maintenance: Ensure the machine is properly calibrated and maintained to prevent defects.

7. What materials are typically dimpled using dimpling machines?

- Aluminum alloys: Widely used in aircraft and automotive industries.

- Stainless steel: Possesses high strength and resistance to corrosion.

- Titanium: Strong and lightweight, suitable for aerospace applications.

- Carbon steel: Used in various industries due to its strength and durability.

- Magnesium alloys: Lightweight and corrosion-resistant, commonly used in aerospace and electronics.

8. What safety precautions should be taken when operating a dimpling machine?

- Wear appropriate PPE: Safety glasses, gloves, earplugs, and protective clothing.

- Maintain a clean and organized work area: Prevent tripping hazards and debris from entering the machine.

- Secure the workpiece: Ensure the workpiece is firmly clamped or held in place to prevent it from moving during dimpling.

- Never reach into the machine while it is operating: Keep hands clear of the moving parts.

- Follow electrical safety protocols: Handle electrical connections and cables with care, ensuring they are not damaged or loose.

9. What is the difference between dimpling and countersinking?

- Dimpling: Creates a raised dimple on the surface of the material, typically used for flush head fasteners.

- Countersinking: Creates a recessed area on the surface of the material, typically used for countersunk head fasteners.

- Purpose: Dimpling provides a flush surface for fasteners, while countersinking allows fasteners to be recessed below the material’s surface.

10. How do you handle production variances that occur during the dimpling process?

- Identify the source of variance: Analyze machine settings, material properties, or operator technique.

- Adjust machine parameters: Calibrate the machine or modify dimpling force, dwell time, or tool size as needed.

- Inspect and adjust materials: Check for material thickness variations or defects, and make adjustments accordingly.

- Retrain operators: Provide additional training or supervision to ensure consistent operating techniques.

- Monitor quality and make continuous improvements: Regularly review dimpling results and implement corrective actions to minimize variances.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dimpling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dimpling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dimpling Machine Operators are responsible for operating and maintaining dimpling machines, which are used to create dimples in metal surfaces. Dimples are small indentations that increase the strength and durability of the metal. Dimpling Machine Operators must be able to accurately and consistently operate the machine, and must also be able to identify and correct any problems that may arise.

1. Set up and operate dimpling machine

Dimpling Machine Operators are responsible for setting up and operating the dimpling machine. This includes loading the machine with the correct materials, setting the machine to the correct specifications, and starting and stopping the machine.

- Load the machine with the correct materials. This includes the metal sheets that will be dimpled, as well as the dimpling dies.

- Set the machine to the correct specifications. This includes the dimple size, the dimple depth, and the dimple spacing.

- Start and stop the machine. Dimpling Machine Operators must be able to start and stop the machine safely and efficiently.

2. Monitor the dimpling process

Dimpling Machine Operators must monitor the dimpling process to ensure that the dimples are being created correctly. This includes checking the dimple size, the dimple depth, and the dimple spacing. Dimpling Machine Operators must also be able to identify and correct any problems that may arise.

- Check the dimple size. Dimpling Machine Operators must ensure that the dimples are being created to the correct size.

- Check the dimple depth. Dimpling Machine Operators must ensure that the dimples are being created to the correct depth.

- Check the dimple spacing. Dimpling Machine Operators must ensure that the dimples are being created to the correct spacing.

- Identify and correct any problems. Dimpling Machine Operators must be able to identify and correct any problems that may arise during the dimpling process.

3. Maintain the dimpling machine

Dimpling Machine Operators are responsible for maintaining the dimpling machine. This includes cleaning the machine, lubricating the machine, and making any necessary repairs. Dimpling Machine Operators must also be able to troubleshoot the machine and identify any potential problems.

- Clean the machine. Dimpling Machine Operators must clean the machine regularly to remove any dirt or debris.

- Lubricate the machine. Dimpling Machine Operators must lubricate the machine regularly to keep it running smoothly.

- Make any necessary repairs. Dimpling Machine Operators must be able to make any necessary repairs to the machine.

- Troubleshoot the machine. Dimpling Machine Operators must be able to troubleshoot the machine and identify any potential problems.

4. Maintain a safe work environment

Dimpling Machine Operators must maintain a safe work environment. This includes wearing the proper safety gear, following all safety procedures, and keeping the work area clean and organized.

- Wear the proper safety gear. Dimpling Machine Operators must wear the proper safety gear, including safety glasses, earplugs, and gloves.

- Follow all safety procedures. Dimpling Machine Operators must follow all safety procedures, including lockout/tagout procedures.

- Keep the work area clean and organized. Dimpling Machine Operators must keep the work area clean and organized to prevent accidents.

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Dimpling Machine Operator position:

1. Research the company and the position

Before you go to your interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the position. You can research the company’s website, LinkedIn page, and Glassdoor reviews. You can also reach out to your network to see if anyone knows anything about the company or the position.

- Visit the company’s website. This is a great way to learn about the company’s history, mission, values, and products or services.

- Check out the company’s LinkedIn page. This is a great way to learn about the company’s culture and to see what employees are saying about the company.

- Read Glassdoor reviews. Glassdoor is a website where employees can anonymously review their companies. This can be a great way to get an inside look at the company and to see what employees are saying about the position you are applying for.

- Reach out to your network. See if anyone you know knows anything about the company or the position. This can be a great way to get an inside scoop and to learn more about the company.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about yourself. This is a common interview question that gives you the opportunity to introduce yourself and to highlight your skills and experience.

- Why are you interested in this position? This is another common interview question that gives you the opportunity to explain why you are interested in the position and why you are the best person for the job.

- What are your strengths? This is a question that gives you the opportunity to highlight your strengths and to explain how they can benefit the company.

- What are your weaknesses? This is a question that gives you the opportunity to explain your weaknesses and to show how you are working to overcome them.

- Why should we hire you? This is a question that gives you the opportunity to summarize your skills and experience and to explain why you are the best person for the job.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are taking the interview seriously.

- Dress professionally. This means wearing a suit or business casual attire.

- Arrive on time. Punctuality shows that you are respectful of the interviewer’s time.

4. Be yourself and be confident

The most important thing is to be yourself and to be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be yourself and let your personality shine through.

- Be yourself. Don’t try to be someone you’re not.

- Be confident. Believe in yourself and your abilities.

5. Ask questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company and the position. It is also a good way to show that you are interested in the position and that you are taking the interview seriously.

- Ask about the company’s culture.

- Ask about the position’s responsibilities.

- Ask about the company’s future plans.

- Ask about the company’s benefits package.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Dimpling Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.