Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dip-Lube Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dip-Lube Operator so you can tailor your answers to impress potential employers.

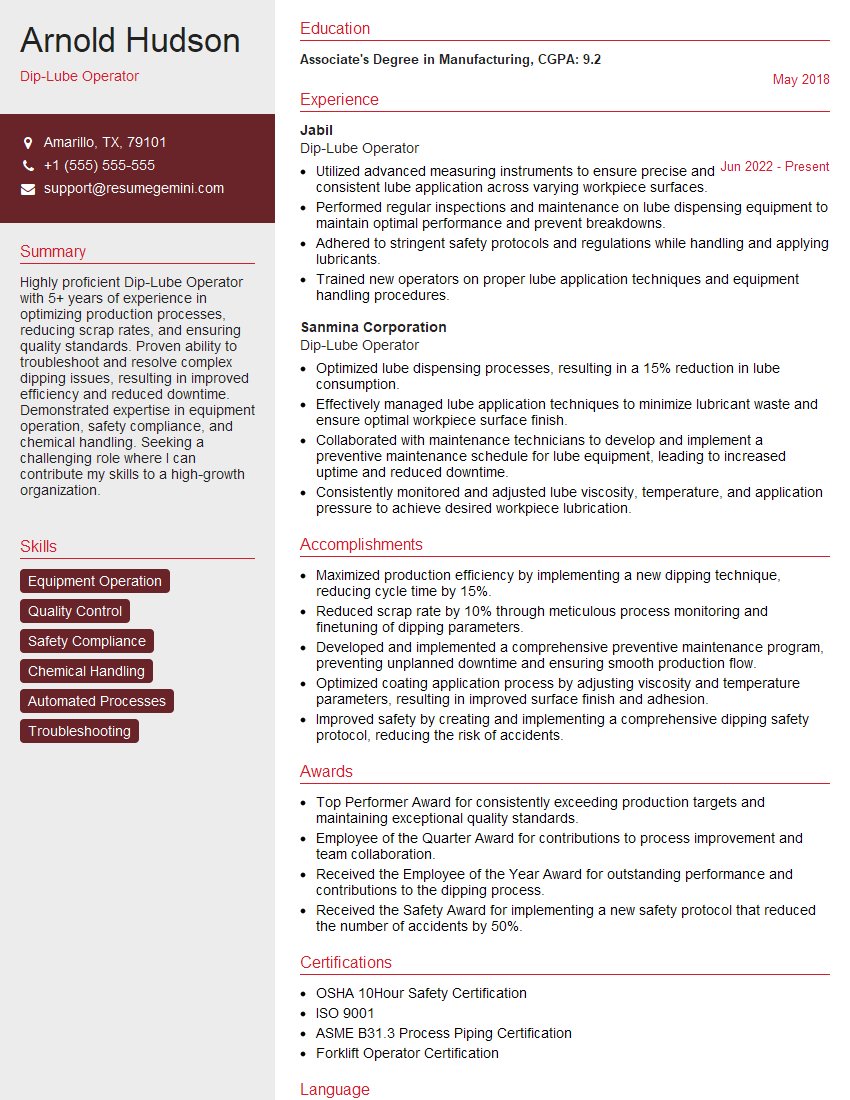

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dip-Lube Operator

1. Describe the key responsibilities of a Dip-Lube Operator.

As a Dip-Lube Operator, my primary responsibilities include:

- Operating and monitoring dip-lubrication systems to ensure smooth and efficient lubrication of machinery and equipment.

- Conducting regular inspections, maintenance, and repairs to ensure the proper functioning of lubrication systems and related components.

2. What safety measures should be followed while working in a Dip-Lube environment?

Personal Protective Equipment

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and coveralls, to prevent exposure to hazardous substances.

Safe Handling of Lubricants

- Handling lubricants properly, including safe storage, disposal, and avoiding skin contact.

Fire Prevention

- Maintaining a clean and organized work area to minimize fire hazards.

3. Explain the process of setting up and operating a dip-lubrication system.

- Mount the lubrication system according to the manufacturer’s specifications.

- Fill the reservoir with the appropriate lubricant.

- Connect the lubrication lines to the equipment to be lubricated.

- Set the operating parameters, such as the lubrication interval and duration.

- Start the system and monitor its operation to ensure it is functioning properly.

4. How do you determine the appropriate lubrication interval and quantity for a given machine?

- Refer to the equipment manufacturer’s recommendations.

- Consider the operating conditions, such as temperature, load, and speed.

- Monitor the machine’s performance and adjust the lubrication schedule as needed.

5. What maintenance tasks are typically performed on dip-lubrication systems?

- Regularly inspect and clean the lubrication system, including the reservoir, lines, and filters.

- Check and adjust the lubrication interval and duration.

- Replace worn or damaged components.

6. How do you troubleshoot common problems associated with dip-lubrication systems?

- Identify the problem by observing the system’s operation and checking for leaks, blockages, or other irregularities.

- Determine the cause of the problem by referring to troubleshooting guides or consulting with experienced technicians.

- Implement appropriate corrective actions, such as cleaning, adjusting, or replacing components.

7. What types of lubricants are commonly used in dip-lubrication systems?

- Mineral oils

- Synthetic oils

- Grease

8. What is the role of filters in a dip-lubrication system?

- Remove contaminants from the lubricant, such as metal particles, dirt, and water.

- Extend the life of the lubricant and lubricated components.

9. How do you ensure the quality of the lubricants used in dip-lubrication systems?

- Purchase lubricants from reputable suppliers.

- Store lubricants properly to prevent contamination.

- Monitor lubricant quality through regular testing.

10. What is your experience with PLC-controlled dip-lubrication systems?

I have several years of experience working with PLC-controlled dip-lubrication systems. I am proficient in programming and troubleshooting these systems to ensure optimal performance and reliability.

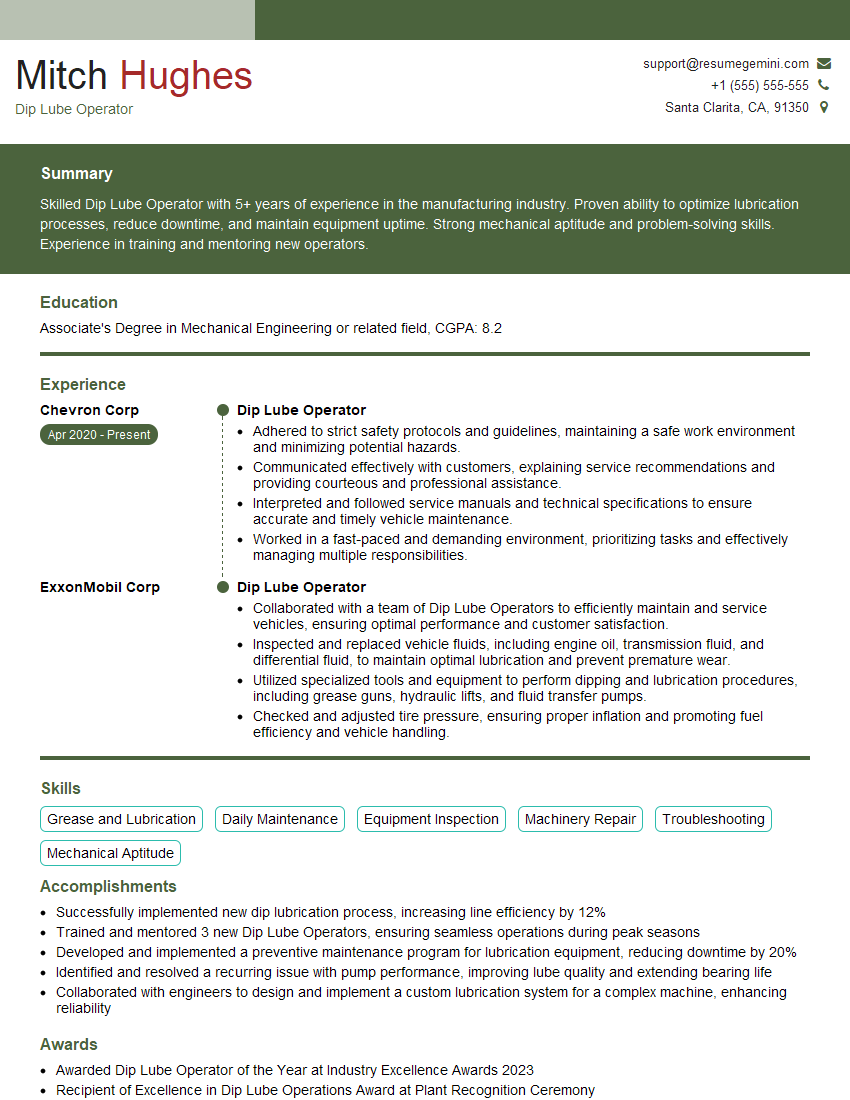

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dip-Lube Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dip-Lube Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Equipment Operation

Operate and maintain dipping and lubrication equipment.

- Set up and adjust equipment according to specifications.

- Monitor equipment performance and make necessary adjustments.

- Troubleshoot and repair equipment malfunctions.

- Ensure that equipment is clean and well-maintained.

2. Material Handling

Handle and store materials safely and efficiently.

- Unload and load materials from storage areas.

- Inspect materials for defects and reject damaged items.

- Maintain inventory levels and replenish supplies as needed.

- Follow proper safety procedures when handling materials.

3. Quality Control

Inspect and test products to ensure quality standards are met.

- Visually inspect products for defects such as scratches, dents, and discoloration.

- Conduct functional tests to ensure products are operating properly.

- Identify and document any defects or non-conformances.

- Implement corrective actions to address quality issues.

4. Safety and Compliance

Adhere to all safety and compliance regulations.

- Use proper personal protective equipment (PPE).

- Follow established safety procedures and protocols.

- Maintain a clean and organized work area.

- Report any accidents or injuries immediately.

Interview Tips

1. Research the Company and Position

Thoroughly research the company and the Dip-Lube Operator position. Understand the company’s mission, values, and products/services.

- Visit the company website and social media pages.

- Read industry news and articles to stay updated on the latest trends.

- Network with professionals in the field to gain insights.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. This will help you feel more confident and articulate during the interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Describe your experience in equipment operation and maintenance.

- How do you ensure quality standards are met?

3. Highlight Your Relevant Skills

Emphasize your relevant skills and experience during the interview. Use specific examples to demonstrate how you have successfully performed the key job responsibilities.

- Highlight your experience in operating and maintaining dipping and lubrication equipment.

- Share examples of how you have improved quality standards through your work.

- Describe your commitment to safety and compliance.

4. Ask Thoughtful Questions

Towards the end of the interview, ask thoughtful questions to show your interest and engagement. This is an opportunity to clarify any details about the position and company.

- What is the company’s culture like?

- What are the expectations for this role in the first 90 days?

- What opportunities for professional development are available?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dip-Lube Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!