Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dipper Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

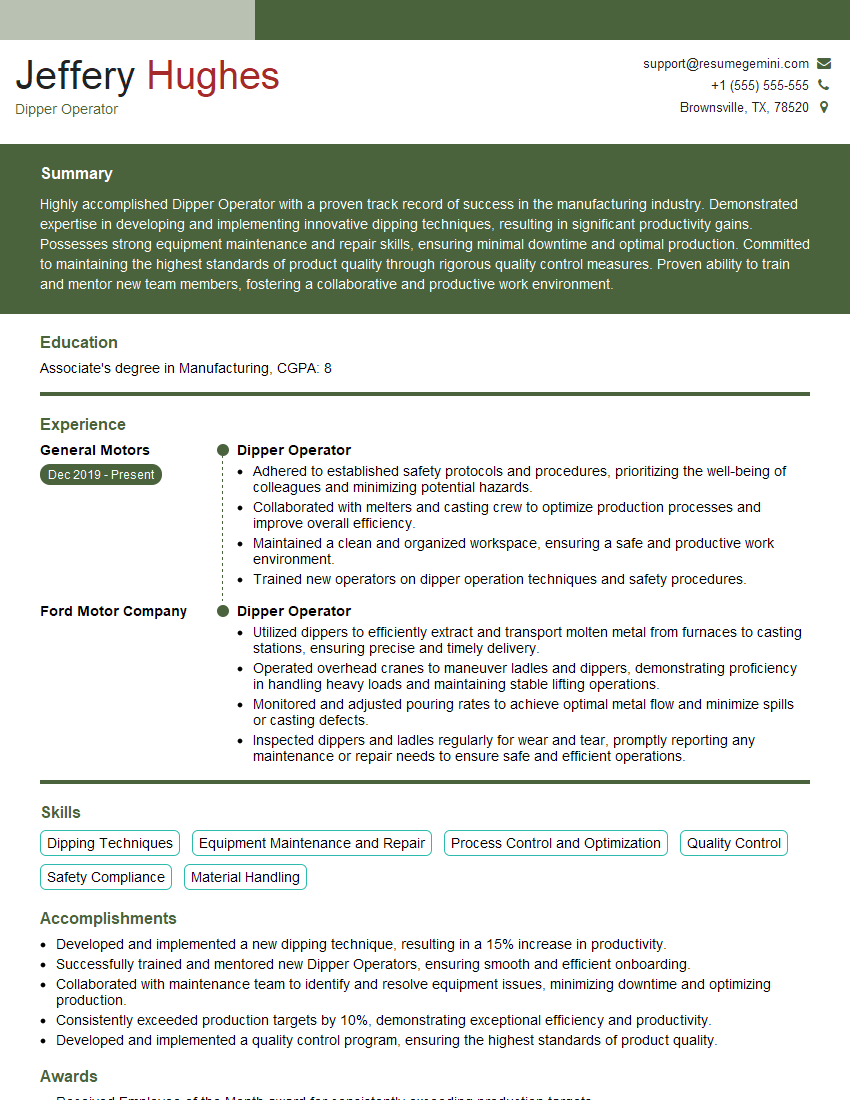

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dipper Operator

1. What are the main responsibilities of a Dipper Operator?

The main responsibilities of a Dipper Operator include:

- Operating a dipper to collect and transport molten metal or other materials.

- Controlling the temperature of the molten metal or other materials.

- Ensuring that the molten metal or other materials are safely and efficiently transferred to the desired location.

2. What are the different types of dippers used in the industry?

Types of Dippers

- Bottom Pour Dippers

- Tilt Pour Dippers

- Air Hoist Dippers

- Floor Pour Dippers

3. What are the safety precautions that must be taken when operating a dipper?

The safety precautions that must be taken when operating a dipper include:

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and a hard hat.

- Inspecting the dipper and its components before each use.

- Following proper operating procedures.

- Being aware of the surroundings and potential hazards.

4. What are the different types of materials that can be dipped?

The different types of materials that can be dipped include:

- Molten metals, such as aluminum, steel, and copper.

- Molten salts.

- Molten glass.

- Other molten materials.

5. What are the factors that affect the dipping process?

The factors that affect the dipping process include:

- The type of material being dipped.

- The temperature of the molten material.

- The size and shape of the dipper.

- The speed of the dipping process.

6. What are the different methods of dipping?

Methods of Dipping

- Manual Dipping

- Automated Dipping

7. What are the quality control procedures that are used in the dipping process?

The quality control procedures that are used in the dipping process include:

- Monitoring the temperature of the molten material.

- Inspecting the dipped products for defects.

- Testing the dipped products to ensure that they meet the desired specifications.

8. What are the troubleshooting tips for common problems that can occur during the dipping process?

The troubleshooting tips for common problems that can occur during the dipping process include:

- If the molten material is too cold, it may not flow properly into the dipper.

- If the molten material is too hot, it may damage the dipper or the dipped products.

- If the dipper is too small, it may not be able to hold enough molten material.

- If the dipper is too large, it may be difficult to control.

- If the dipping speed is too fast, the dipped products may not be properly coated.

- If the dipping speed is too slow, the dipped products may be overcoated.

9. What is the importance of regular maintenance for dipping equipment?

Regular maintenance for dipping equipment is important to ensure that the equipment is operating safely and efficiently. It can help to prevent breakdowns and extend the lifespan of the equipment.

10. What are the career advancement opportunities for Dipper Operators?

Career advancement opportunities for Dipper Operators include:

- Supervisor.

- Manager.

- Quality control inspector.

- Maintenance technician.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dipper Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dipper Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dipper Operators are primarily responsible for operating dipping equipment in a variety of industrial settings, ensuring that products meet specified standards and quality requirements.

1. Operation and Maintenance of Dipping Equipment

Responsible for operating and maintaining dipping equipment, including dip tanks, conveyors, and drying ovens.

- Monitor and adjust equipment settings to ensure optimal performance and product quality.

- Conduct regular maintenance and repairs to keep equipment in good working order.

2. Product Handling and Inspection

Handle and inspect products during the dipping process, ensuring that they meet specifications.

- Load and unload products from dipping equipment.

- Inspect products for defects, such as scratches, dents, or uneven coatings.

- Sort and segregate products based on quality.

3. Quality Control and Documentation

Maintain quality control standards and document dipping processes to ensure compliance.

- Monitor and record dipping parameters, such as temperature, immersion time, and coating thickness.

- Maintain accurate records of all dipping operations for quality control purposes.

- Calibrate and maintain measuring and testing equipment.

4. Safety and Environmental Compliance

Adhere to safety and environmental regulations while operating dipping equipment.

- Wear appropriate personal protective equipment (PPE).

- Follow established safety protocols for handling chemicals and hazardous materials.

- Dispose of waste materials in accordance with environmental regulations.

Interview Tips

To ace an interview for a Dipper Operator position, it is crucial to prepare thoroughly and demonstrate your skills and experience. Here are some tips to help you succeed:

1. Research the Company and Position

Familiarize yourself with the company’s background, products, and industry reputation. Research the specific job responsibilities and requirements for the Dipper Operator position.

- Visit the company’s website and social media pages.

- Read industry news and articles to gain insights into the company’s operations.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating dipping equipment, handling products, and maintaining quality standards. Quantify your accomplishments whenever possible to demonstrate your impact.

- Describe your previous roles and responsibilities in detail, highlighting any transferable skills.

- Provide specific examples of projects where you successfully operated dipping equipment and ensured product quality.

3. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivations. Practice answering these questions confidently and concisely.

- Why are you interested in this position?

- Tell me about your experience operating dipping equipment.

- How do you ensure the quality of products during the dipping process?

4. Be Prepared to Discuss Safety and Compliance

Dipper Operators are responsible for adhering to safety and environmental regulations. Be prepared to discuss your understanding of these protocols and your commitment to following them.

- Explain your knowledge of PPE, hazardous material handling, and waste disposal procedures.

- Discuss your experience in maintaining a safe and compliant work environment.

5. Ask Thoughtful Questions

Asking thoughtful questions during the interview demonstrates your interest in the position and the company. Prepare a few questions that show your understanding of the industry and your desire to contribute.

- What are the company’s current goals and priorities?

- How does the Dipper Operator role contribute to the company’s success?

- Are there any opportunities for professional development or advancement within the company?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Dipper Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Dipper Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.