Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Direct Chill Caster (DC Caster) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

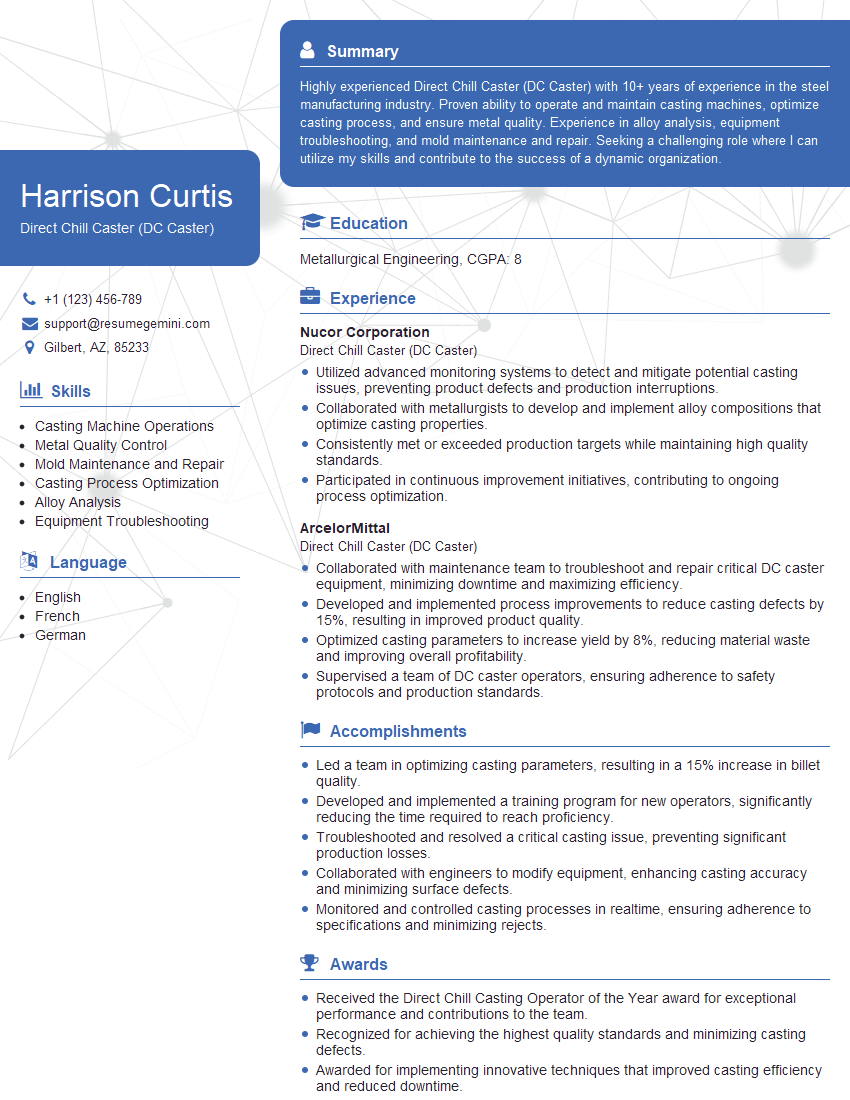

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Direct Chill Caster (DC Caster)

1. Explain the principle of Direct Chill (DC) Casting?

In Direct Chill (DC) Casting, molten metal is continuously fed into a water-cooled mold, where it solidifies into a billet. The mold oscillates vertically while the billet is withdrawn, ensuring uniform cooling and solidification.

2. Describe the process of grain refinement in DC Casting?

Grain Modification

- Adding grain refiners like titanium or boron to the melt

- Reduces grain size by promoting nucleation

Grain Size Control

- Controlled cooling rate through mold design and withdrawal speed

- Slower cooling leads to larger grains, while faster cooling promotes finer grains

3. How do you optimize productivity in DC Casting?

- Optimize melt temperature and casting speed for desired grain structure

- Minimize surface defects by controlling mold oscillation and withdrawal parameters

- Regular mold maintenance to prevent sticking and ensure smooth casting

- Implement automation and process control systems for efficient operation

4. Explain the role of the electromagnetic stirrer (EMS) in DC Casting?

- Creates electromagnetic forces in the melt

- Induces melt motion, reducing segregation and promoting uniform composition

- Improves grain refinement and reduces defects

5. How do you troubleshoot surface defects in DC Casting?

- Identify the type of surface defect (e.g., pinholes, cracks, slivers)

- Analyze casting parameters such as mold oscillation, casting speed, and melt temperature

- Inspect mold condition and address any imperfections or contamination

- Adjust casting parameters or implement corrective measures to eliminate defects

6. Explain the importance of mold cooling in DC Casting?

- Controls the cooling rate and solidification structure of the billet

- Ensures uniform heat transfer and prevents thermal gradients

- Optimizes grain size and reduces the risk of defects

7. How do you maintain the quality of the DC-casted billet?

- Monitor and control casting parameters to ensure consistent quality

- Regularly inspect the billet for surface defects and internal imperfections

- Implement quality control measures such as non-destructive testing and metallurgical analysis

- Maintain accurate records and documentation of casting and quality control processes

8. Describe the safety precautions to be taken during DC Casting?

- Wear appropriate personal protective equipment (PPE)

- Follow established safety protocols and operating procedures

- Monitor equipment and processes for potential hazards

- Report any unsafe conditions or potential hazards immediately

9. What are the challenges associated with DC Casting of high-strength alloys?

- Controlling solidification and avoiding hot tearing

- Minimizing grain coarsening during casting and homogenization

- Preventing surface defects due to high-temperature sensitivity

- Optimizing casting parameters for specific alloy compositions

10. Explain the use of process simulation in DC Casting?

- Predicts casting behavior and optimizes process parameters

- Identifies potential defects and suggests corrective measures

- Reduces trial-and-error casting, saving time and resources

- Facilitates the development of new alloys and casting processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Direct Chill Caster (DC Caster).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Direct Chill Caster (DC Caster)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Direct Chill Caster plays a crucial role in the metallurgical process of transforming molten metal into high-quality billets. Key responsibilities include:

1. Casting and Solidification Process

Oversee the casting and solidification of molten metal, ensuring optimal billet quality.

- Monitor and control casting parameters such as temperature, flow rate, and mold dimensions.

- Maintain the integrity of the casting equipment and troubleshoot any issues promptly.

2. Billet Quality Management

Inspect and evaluate billet quality, ensuring adherence to specifications.

- Conduct visual and non-destructive testing to detect surface defects, internal inconsistencies, and dimensional accuracy.

- Document and report quality control findings, adhering to established standards.

3. Machine Operation and Maintenance

Operate and maintain the direct chill casting machine, ensuring efficient and safe production.

- Perform routine inspections and maintenance tasks to optimize machine performance.

- Troubleshoot and resolve operational issues, minimizing downtime and maximizing productivity.

4. Process Optimization

Analyze and implement process improvements to enhance casting efficiency and product quality.

- Monitor and track key performance indicators, identifying areas for improvement.

- Collaborate with engineers and metallurgists to develop and deploy innovative solutions.

Interview Tips

To ace your interview for the Direct Chill Caster position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s operations, market position, and industry trends.

- Visit the company website and social media pages.

- Read industry publications and news articles to gain insights.

2. Highlight Your Technical Expertise

Emphasize your understanding of direct chill casting processes, billet quality control, and machine operations.

- Provide specific examples of your experience in these areas.

- Quantify your achievements and results whenever possible.

3. Showcase Your Problem-Solving Abilities

Interviewers will be interested in your ability to troubleshoot and resolve operational issues efficiently.

- Describe real-world examples where you identified and solved machine problems.

- Explain your approach to analyzing and resolving complex technical challenges.

4. Prepare Questions to Ask

Asking thoughtful questions during the interview shows your engagement and interest in the role and company.

- Inquire about the company’s future plans and growth strategy.

- Ask about the specific challenges and opportunities within the direct chill casting department.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Direct Chill Caster (DC Caster) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.