Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Direct Chill Casting Operator (DC Casting Operator) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

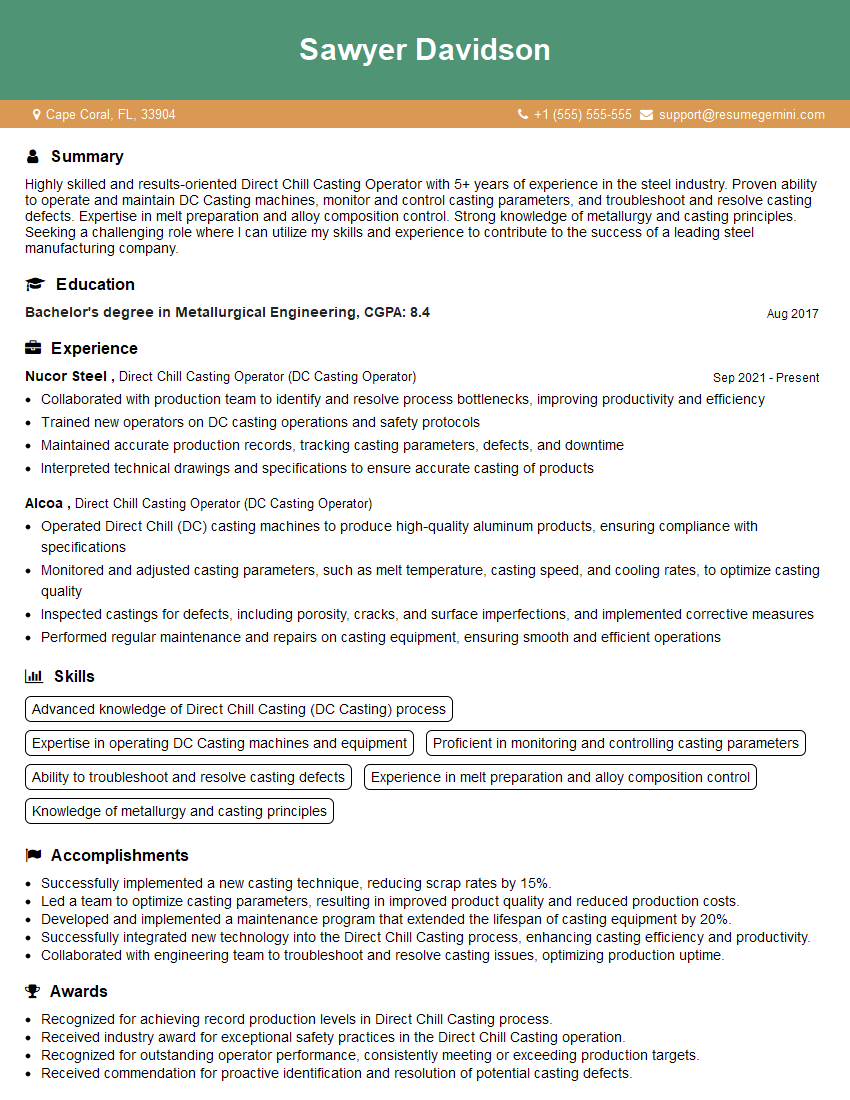

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Direct Chill Casting Operator (DC Casting Operator)

1. Describe the process of direct chill casting in detail.

Direct Chill Casting (DC Casting) is a continuous casting process used to produce aluminum billets, rods, and slabs. Here’s a detailed explanation of the process:

- Molten metal preparation: Molten aluminum is prepared in a melting furnace, where it is heated to a specific temperature and degassed to remove impurities.

- Casting: The molten aluminum is poured into a water-cooled copper mold, which has a shaped cavity to form the desired product. As the molten metal enters the mold, it solidifies rapidly due to the contact with the cold mold, forming a solid shell.

- Cooling and solidification: The solid shell continues to move downward through the mold as the molten metal continuously enters from the top. The cooling process is controlled by the water flow rate in the mold, which determines the solidification rate and the properties of the cast product.

- Extraction: Once the product is fully solidified, it is extracted from the mold using a puller system. The puller controls the extraction speed to ensure a consistent casting rate.

- Secondary operations: The extracted product may undergo further processing, such as heat treatment, sawing, or straightening, to meet specific requirements.

2. Explain the different types of Direct Chill casting machines and their applications.

Vertical DC Casting Machines

- Suitable for producing round billets, rods, and slabs.

- The mold is positioned vertically, and the molten metal is poured from the top.

- Used in the production of aluminum alloys for extrusion, rolling, and forging.

Horizontal DC Casting Machines

- Used for producing flat products such as plates and strips.

- The mold is positioned horizontally, and the molten metal is poured into the side of the mold.

- Applications include the production of aluminum alloys for automotive and aerospace industries.

Inclined DC Casting Machines

- A combination of vertical and horizontal machines.

- The mold is inclined at an angle, allowing for the production of both round and flat products.

- Offers flexibility in product geometry and alloy selection.

3. What are the critical process parameters in Direct Chill Casting and how do they affect the quality of the cast product?

- Casting speed: Determines the solidification rate and the grain structure of the cast product.

- Cooling rate: Controlled by the water flow rate in the mold, affects the mechanical properties and microstructure of the product.

- Metal temperature: The temperature of the molten metal influences the fluidity and solidification behavior.

- Mold geometry: The shape of the mold cavity affects the product dimensions and surface quality.

- Alloy composition: The type and amount of alloying elements impact the final properties of the cast product.

4. Describe the key safety measures and precautions that must be observed during Direct Chill Casting operations.

- Protective clothing: Operators must wear appropriate protective clothing, including heat-resistant suits, gloves, and safety glasses.

- Hazard identification: Potential hazards such as high temperatures, molten metal handling, and electrical equipment must be identified and controlled.

- Emergency procedures: Clear and detailed emergency procedures must be established and communicated to all operators.

- Regular maintenance: Equipment should be inspected and maintained regularly to ensure safe operation.

- Training: Operators must receive proper training on the operation of the casting machine and safety protocols.

5. Explain the role of quality control in Direct Chill Casting and describe the different methods used to ensure product quality.

- Visual inspection: The surface of the cast product is visually inspected for defects such as cracks, porosity, and inclusions.

- Ultrasonic testing: Used to detect internal defects within the cast product.

- Dimensional measurement: The dimensions of the cast product are checked to ensure they meet specifications.

- Mechanical testing: Tensile testing, hardness testing, and other mechanical tests are performed to evaluate the mechanical properties of the cast product.

- Chemical analysis: The chemical composition of the cast product is analyzed to ensure it meets the desired specifications.

6. Describe the different types of defects that can occur in Direct Chill Casting and explain how to prevent or minimize them.

- Cracks: Caused by thermal stresses or improper cooling. Prevented by controlling casting speed and cooling rate.

- Porosity: Caused by entrapped gases or solidification shrinkage. Minimized by proper degassing and controlled solidification.

- Inclusions: Foreign particles introduced during the casting process. Prevented by using clean raw materials and proper filtration.

- Surface defects: Caused by mold imperfections or splashing of molten metal. Minimized by using smooth molds and controlling the metal flow.

- Dimensional variations: Caused by unstable casting conditions or mold wear. Prevented by maintaining consistent process parameters and regular mold maintenance.

7. Explain how Direct Chill Casting technology has evolved over the years and discuss the latest advancements in the field.

- Automation: Increased automation in casting processes, including automatic mold changing and control systems.

- Advanced cooling systems: Development of more efficient cooling systems to improve product quality and productivity.

- Alloy development: Research and development of new aluminum alloys tailored for Direct Chill Casting applications.

- Process optimization: Use of simulation and modeling tools to optimize casting parameters and reduce defects.

- Sustainability: Focus on reducing energy consumption and waste generation in Direct Chill Casting operations.

8. Describe the skills and qualifications required to be an effective Direct Chill Casting Operator.

- Technical knowledge: Understanding of Direct Chill Casting process, equipment, and metallurgy.

- Operational skills: Ability to operate and monitor casting machines, including mold handling and parameter control.

- Problem-solving: Identifying and resolving operational issues, such as defects or equipment malfunctions.

- Quality assurance: Knowledge of quality control procedures and ability to inspect cast products.

- Communication and teamwork: Effective communication skills and ability to work as part of a team.

9. Explain how you would troubleshoot a Direct Chill Casting machine that is producing defective products.

- Identify the defect: Determine the type of defect and its possible causes.

- Check process parameters: Review casting speed, cooling rate, and other process parameters to identify any deviations.

- Inspect equipment: Examine the casting machine for any mechanical issues, mold wear, or cooling system malfunctions.

- Analyze raw materials: Check the quality of the molten aluminum and any alloying elements used.

- Implement corrective actions: Adjust process parameters, repair equipment, or replace raw materials as necessary.

- Monitor results: Observe the cast products after implementing corrective actions to ensure the defect has been resolved.

10. Describe your experience in working with different types of Direct Chill Casting machines and alloys.

- Describe specific machines and alloys you have worked with.

- Highlight your skills in operating and troubleshooting these machines.

- Explain how your experience has contributed to your understanding of Direct Chill Casting technology.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Direct Chill Casting Operator (DC Casting Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Direct Chill Casting Operator (DC Casting Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Direct Chill Casting Operator (DC Casting Operator) plays a crucial role in the production process of aluminum, by monitoring and operating the direct chill casting machine. Their responsibilities encompass various aspects of the casting process, ensuring the production of high-quality aluminum products.

1. Machine Operation and Monitoring

The DC Casting Operator is responsible for operating and monitoring the direct chill casting machine. This involves:

- Starting, stopping, and adjusting the machine to achieve optimal casting parameters.

- Monitoring machine performance and taking corrective actions to prevent or address any issues that may arise.

- Ensuring that the machine is maintained and serviced regularly to prevent breakdowns and ensure smooth operation.

2. Metal Preparation and Casting Process

The DC Casting Operator plays a key role in preparing the metal and overseeing the casting process. Responsibilities include:

- Preparing the molten aluminum for casting by ensuring its proper temperature, composition, and purity.

- Monitoring and controlling the molten aluminum flow into the casting mold.

- Adjusting casting parameters, such as casting speed and cooling rate, to achieve the desired product quality.

3. Quality Control and Inspection

The DC Casting Operator is responsible for maintaining product quality by:

- Continuously monitoring the casting process and conducting visual inspections to identify any potential defects.

- Sampling and testing the cast products to ensure compliance with quality standards.

- Documenting and reporting any quality deviations and taking corrective actions to prevent their recurrence.

4. Safety and Environmental Compliance

The DC Casting Operator must prioritize safety and environmental compliance by:

- Adhering to safety protocols and wearing appropriate protective gear to prevent accidents or injuries.

- Understanding and implementing environmental regulations related to the casting process.

- Managing waste and emissions effectively to minimize the environmental impact.

Interview Tips

To ace the interview for a DC Casting Operator position, it is essential to prepare thoroughly and showcase your knowledge and skills. Here are some tips to help you succeed:

1. Research the Company and Position

Before the interview, conduct thorough research on the company and the specific DC Casting Operator role. This will show the interviewer that you are genuinely interested in the opportunity and have taken the time to learn about the company’s operations and requirements.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating direct chill casting machines or similar equipment. Quantify your accomplishments and provide specific examples that demonstrate your technical abilities and problem-solving skills. Also, highlight your knowledge of metal casting processes and quality control procedures.

3. Prepare for Technical Questions

Be prepared to answer technical questions related to the casting process, machine operation, and quality control. Review the basics of direct chill casting, including the principles of solidification, heat transfer, and defect formation. Practice troubleshooting common casting issues and demonstrate your understanding of corrective actions.

4. Show Your Safety and Environmental Awareness

Highlight your understanding of safety protocols and environmental regulations applicable to the casting industry. Explain how you would ensure a safe work environment and minimize the environmental impact of the casting process. Describe your experience in waste management and emission control.

5. Be Confident and Enthusiastic

Confidence and enthusiasm can make a positive impact on the interviewer. Maintain a positive attitude, clearly articulate your answers, and demonstrate your passion for the field. Show that you are eager to learn, grow, and contribute to the team’s success.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Direct Chill Casting Operator (DC Casting Operator) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.