Feeling lost in a sea of interview questions? Landed that dream interview for Disc Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Disc Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

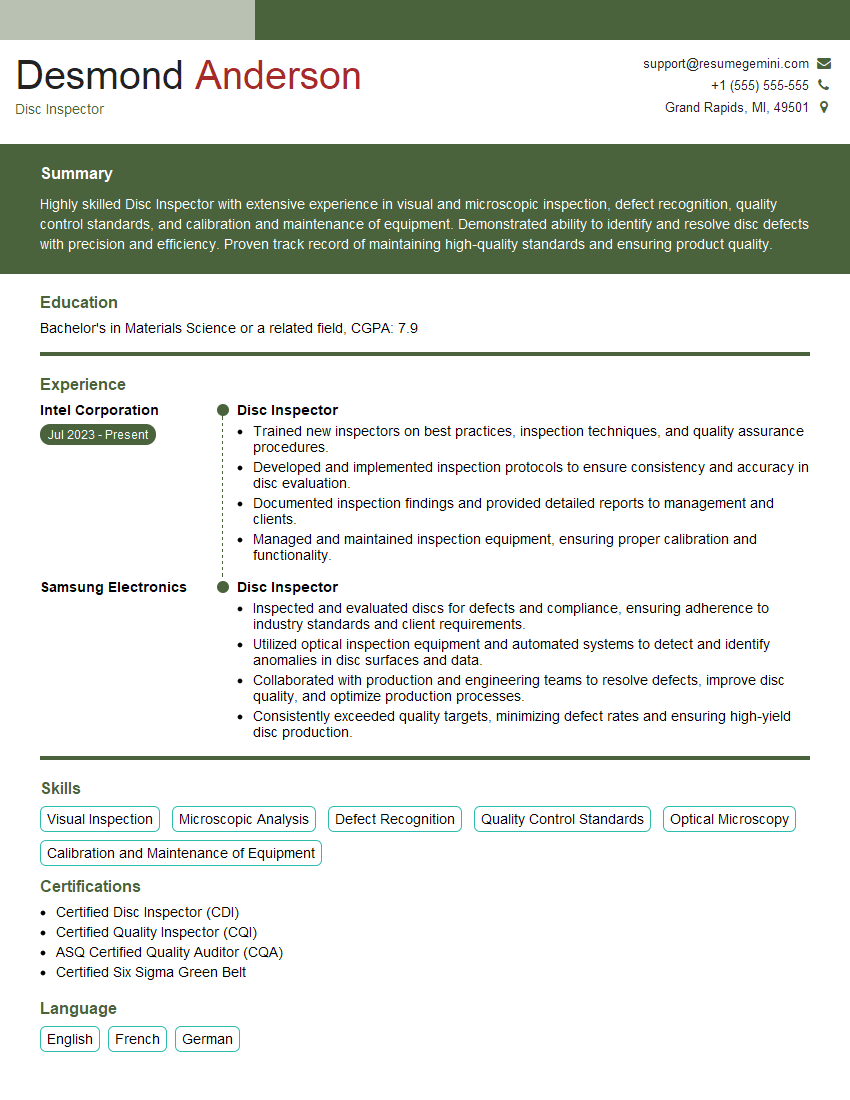

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Disc Inspector

1. Tell me about your experience in disc inspection?

In my previous role as a Disc Inspector at XYZ Company, I was responsible for:

- Inspecting and testing optical discs (CDs, DVDs, Blu-rays) to ensure they met quality standards

- Utilizing specialized equipment to identify and rectify defects, such as scratches, pits, and data errors

- Maintaining detailed inspection records and providing timely reports to management

2. What are the key technical skills required for effective disc inspection?

Quality Control Techniques:

- Understanding of ISO 9001 and other quality control standards

- Ability to apply statistical process control methods

Optical Disc Technology:

- Knowledge of CD, DVD, and Blu-ray disc formats

- Understanding of disc manufacturing processes

Inspection Equipment:

- Proficiency in using optical disc analyzers

- Experience with microscopy and data error testing tools

3. Can you describe the process of disc inspection in detail?

The disc inspection process typically involves several key steps:

- Visual Inspection: Examine the disc surface for scratches, smudges, or other physical defects.

- Optical Analysis: Use specialized equipment to analyze the disc’s data tracks and identify errors.

- Data Integrity Testing: Verify the accuracy and integrity of the data stored on the disc.

- Defect Classification: Categorize defects based on severity and impact on disc functionality.

- Reporting and Documentation: Record inspection results and communicate them to stakeholders.

4. What are the common types of disc defects you have encountered?

Common types of disc defects include:

- Scratches: Physical marks on the disc’s surface that can impair data reading.

- Pits: Small indentations in the disc’s surface that can cause data loss.

- Data Errors: Incorrect or missing data on the disc that can result in read failures.

- Edge Damage: Defects around the disc’s edge that can affect its stability and handling.

- Manufacturing Defects: Flaws in the disc’s production process that can lead to structural or performance issues.

5. How do you prioritize different types of disc defects?

I prioritize disc defects based on their severity and potential impact on the disc’s functionality. Critical defects, such as data errors or structural damage, receive the highest priority and require immediate attention. Less severe defects, such as minor scratches or smudges, may be ranked lower and can be addressed as needed.

6. What measures do you take to ensure the accuracy and reliability of your disc inspections?

- Equipment Calibration: Regularly calibrate inspection equipment to ensure optimal performance and accuracy.

- Process Validation: Validate inspection procedures to ensure they are effective in identifying and classifying defects.

- Sample Inspection: Conduct random sample inspections to verify the consistency and reliability of the inspection process.

- Training and Certification: Maintain up-to-date training and certifications in relevant disc inspection methods and standards.

7. How do you stay informed about the latest advancements in disc inspection technology?

- Industry Conferences: Attend industry conferences and exhibitions to learn about new technologies and innovations.

- Technical Publications: Read technical journals and articles related to disc inspection techniques.

- Vendor Training: Participate in training programs offered by equipment manufacturers to gain insights into the latest advancements.

8. Can you describe a situation where you identified and resolved a complex disc inspection issue?

In my previous role, I encountered a batch of discs that exhibited intermittent data read failures. After thorough investigation, I discovered that the disc surface had microscopic pits caused by a manufacturing defect. By implementing a more rigorous inspection process and adjusting the equipment settings, I was able to identify and reject the affected discs, ensuring the production of high-quality and reliable discs.

9. What is your approach to working effectively in a team environment?

- Communication: Communicate clearly and effectively with team members to ensure everyone is on the same page.

- Collaboration: Work collaboratively to solve problems and achieve shared goals.

- Support: Provide support to team members and seek support when needed.

- Respect: Respect different perspectives and opinions of team members.

10. How do you handle situations where you have tight deadlines and high-pressure demands?

- Prioritization: Prioritize tasks based on urgency and importance.

- Time Management: Utilize time management techniques to stay organized and efficient.

- Delegation: Delegate tasks to others when appropriate to manage workload.

- Communication: Keep stakeholders informed about progress and any potential delays.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Disc Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Disc Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Disc Inspectors play a crucial role in maintaining the quality and accuracy of optical disc production. Their key responsibilities include:

1. Optical Disc Inspection

Inspect optical discs for defects and errors using specialized equipment, such as disc drives and microscopes.

- Identify and classify defects based on established quality standards.

- Log and document inspection results for traceability and quality control.

2. Data Verification

Verify the accuracy and integrity of data on optical discs, including content, file structure, and metadata.

- Use software tools to compare data against reference copies or specifications.

- Identify and resolve any data errors or inconsistencies.

3. Quality Control

Monitor and maintain quality standards for optical disc production.

- Analyze inspection data to identify trends and areas for improvement.

- Collaborate with production teams to implement corrective actions and enhance quality.

4. Troubleshooting

Diagnose and resolve technical issues related to optical discs and inspection equipment.

- Identify the root cause of defects and errors.

- Recommend solutions to mitigate problems and improve production efficiency.

Interview Preparation Tips

Preparing thoroughly for a Disc Inspector interview is essential to showcase your skills and increase your chances of success. Here are some valuable tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This knowledge will help you demonstrate your interest and understanding of the role.

2. Practice Your Technical Skills

Review your knowledge of optical disc inspection techniques, data verification methods, and troubleshooting principles. Consider practicing with sample discs or using online resources.

3. Highlight Your Attention to Detail

Emphasize your meticulous nature and ability to identify and analyze defects or errors with precision. Provide specific examples from your previous experience.

4. Showcase Your Quality Control Experience

Discuss your experience in monitoring and maintaining quality standards in a production environment. Highlight your ability to identify areas for improvement and implement effective corrective actions.

5. Prepare for Behavioral Questions

Be prepared to answer behavioral questions that assess your problem-solving, teamwork, and communication skills. Use the STAR method (Situation, Task, Action, Result) to structure your answers effectively.

6. Example Questions

Here are some common interview questions for Disc Inspectors:

- Describe your experience in inspecting optical discs for defects and errors.

- How do you verify the accuracy and integrity of data on optical discs?

- Provide an example of a time you identified and resolved a technical issue related to optical discs.

- How do you ensure the quality and consistency of optical disc production?

- Tell us about a time you worked effectively as part of a team to improve production processes.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Disc Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.