Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Disc-Pad Knockout Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Disc-Pad Knockout Worker so you can tailor your answers to impress potential employers.

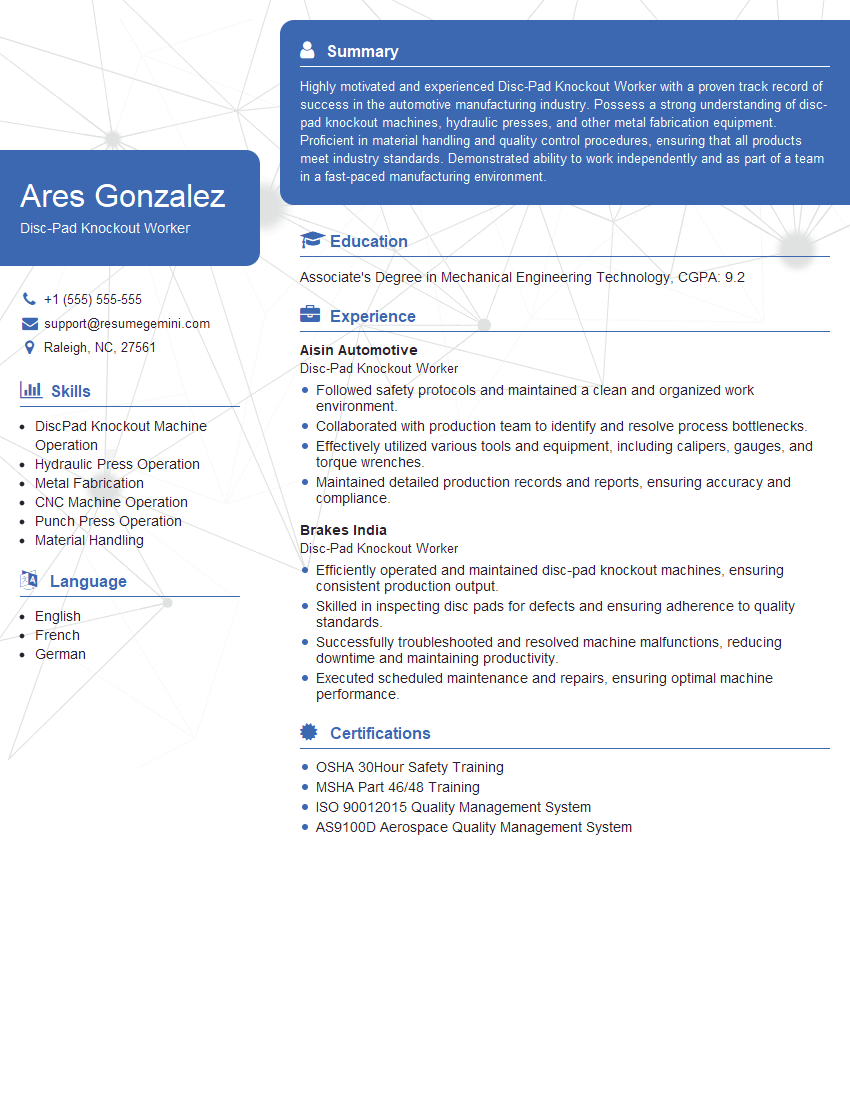

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Disc-Pad Knockout Worker

1. Explain the process of inspecting disc pads?

The process of inspecting disc pads involves several key steps:

- Visual Inspection: Inspect the pads for cracks, tears, or other physical damage. Check their thickness and ensure they meet the minimum thickness specified by the manufacturer.

- Measuring Pad Thickness: Use a caliper to measure the remaining thickness of the pads. Compare it to the minimum thickness required for safe braking.

- Checking for Wear Patterns: Examine the pads for uneven wear or glazing. Uneven wear indicates a problem with the braking system, such as a sticking caliper.

- Assessing Pad Material: Determine if the pad material is suitable for the intended use. Different pad materials have varying friction characteristics and are designed for specific performance requirements.

- Checking Hardware: Inspect the brake hardware, such as retaining clips, shims, and sliders, for any damage or wear. Ensure all hardware is present and in good condition.

2. How do you troubleshoot a disc brake system that is making noise?

Squealing Noise

- Check for glazed pads and replace them if necessary.

- Inspect the brake hardware for proper installation and lubrication.

- Consider using a different pad material with a lower coefficient of friction.

Screeching Noise

- Inspect the pads for wear or contamination.

- Check the rotors for warping or damage.

- Examine the brake calipers and ensure they are functioning properly.

Grinding Noise

- Check for worn-out pads or rotors.

- Inspect the brake calipers for any damage or sticking.

- Examine the brake lines and hoses for leaks or blockages.

3. Describe the different types of disc pads and their applications?

There are several types of disc pads available for different applications:

- Organic Pads: Made from a blend of organic materials, these pads are known for their low noise and good initial bite. They are commonly found on passenger vehicles.

- Ceramic Pads: Constructed from ceramic fibers, these pads offer high performance and durability. They generate less dust and are less prone to fading at high temperatures.

- Semi-Metallic Pads: A combination of organic and metallic materials, these pads provide a balance of performance, durability, and noise reduction. They are suitable for a wide range of vehicles.

- Sintered Metal Pads: Composed of metal powders that are bonded together, these pads offer exceptional durability and high heat resistance. They are commonly used in racing and performance applications.

4. How can you identify and resolve problems related to brake fluid?

Common brake fluid problems include:

- Low Brake Fluid: Inspect the master cylinder for leaks and top up the fluid to the appropriate level.

- Contaminated Brake Fluid: Change the brake fluid if it appears discolored or dirty. Contamination can affect braking performance.

- Air in the Brake Lines: Perform a brake bleed to remove any air from the system. Trapped air can cause a spongy brake pedal.

- Damaged Brake Lines: Inspect the brake lines and hoses for any leaks or damage. Replace any compromised components.

5. Explain the importance of torquing disc brake components to manufacturer specifications.

- Ensures Proper Function: Correct torque ensures that all components are securely fastened, allowing the braking system to function correctly.

- Prevents Safety Hazards: Loose components can lead to brake failure, increasing the risk of accidents.

- Prevents Premature Wear:Properly torqued components minimize wear and tear on the braking system, extending its lifespan.

- Maintains Warranty: Failure to adhere to torque specifications may void the manufacturer’s warranty.

6. What are the safety precautions that should be taken when inspecting and repairing disc brake systems?

- Use Proper Equipment: Wear gloves, safety glasses, and appropriate tools.

- Secure the Vehicle: Park on a level surface, engage the parking brake, and chock the wheels.

- Allow Brakes to Cool: Before inspecting or repairing, allow the brakes to cool down to prevent burns.

- Handle Brake Fluid Safely: Avoid contact with brake fluid and dispose of it properly.

- Inspect Components Thoroughly: Check all components carefully for damage or wear before reassembling.

7. How do you ensure accurate diagnosis and repair of disc brake problems?

- Gather Customer Information: Collect details about the symptoms and any recent repairs or modifications.

- Thorough Inspection: Perform a visual inspection of all brake components, including pads, rotors, calipers, and brake lines.

- Test Drive: Conduct a test drive to assess braking performance and identify any issues.

- Consult Technical Information: Refer to manufacturer specifications and technical manuals for guidance.

- Follow Repair Procedures: Adhere to proper repair techniques and torque specifications to ensure reliable performance.

8. How do you prioritize repairs and determine which components need immediate attention?

- Safety Concerns: Prioritize repairs that impact safety, such as worn pads or damaged brake lines.

- Performance Issues: Address repairs that affect braking performance, such as uneven pad wear or glazed rotors.

- Cost and Availability: Consider the cost and availability of replacement parts when determining the order of repairs.

- Customer Needs: Take into account the customer’s budget and time constraints.

9. How do you communicate repair recommendations to customers effectively?

- Explain the Diagnosis: Clearly explain the problems identified and the reasons behind the recommendations.

- Quantify the Need for Repairs: Provide specific measurements or observations to demonstrate the severity of the issues.

- Discuss Options: Present different repair options with their respective costs and benefits.

- Use Visual Aids: Utilize diagrams or photos to help customers visualize the problems and understand the recommended repairs.

- Listen to Concerns: Address customer questions and discuss any concerns or preferences.

10. Describe your approach to staying updated with the latest advancements in disc brake technology.

- Attend Industry Workshops: Participate in training programs and seminars to enhance skills and knowledge.

- Read Technical Publications: Stay informed by reviewing industry publications, technical manuals, and online resources.

- Consult Manufacturer Websites: Access up-to-date information, repair procedures, and technical bulletins from brake manufacturers.

- Network with Colleagues: Exchange knowledge and experiences with peers in the field.

- Stay Curious: Continuously seek opportunities to learn and explore new technologies and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Disc-Pad Knockout Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Disc-Pad Knockout Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Disc-Pad Knockout Worker is employed in manufacturing to assist in the process of producing brake pads.

1. Knock out disc pads

After the disc pads have been fabricated, a knockout worker will remove them from their mold typically using a punch press or similar machine.

2. Inspect the disc pads

The disc pads will need to be carefully reviewed for any imperfections since they play a vital role in vehicle safety.

3. Package the disc pads

After they pass inspection, the knockout worker will properly package them in a manner that ensures their protection during storage and transport.

4. Troubleshoot problems

The knockout worker may on occasion experience difficulties with machinery and be expected to find a solution, whether that be resolving the issue independently or seeking assistance.

Interview Tips

Here are some tips to help you prepare for your interview for a position as a Disc-Pad Knockout Worker:

1. Research the company

Visit the company’s website and social media pages to learn more about their culture, values, and recent news. This will help you to understand the company’s needs and how your skills and experience can benefit them.

2. Practice your answers

Think about the questions you are likely to be asked in an interview and prepare your answers in advance. This will help you to feel confident and articulate during the interview.

3. Dress professionally

First impressions matter, so be sure to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

4. Be on time

Punctuality is important, so be sure to arrive for your interview on time. This shows the interviewer that you are respectful of their time and that you are serious about the position.

5. Be prepared to talk about your experience

In your interview, you will be asked about your experience and qualifications. Be prepared to discuss your skills and experience in detail, and be sure to highlight any achievements that are relevant to the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Disc-Pad Knockout Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.