Feeling lost in a sea of interview questions? Landed that dream interview for Discharge Door Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Discharge Door Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

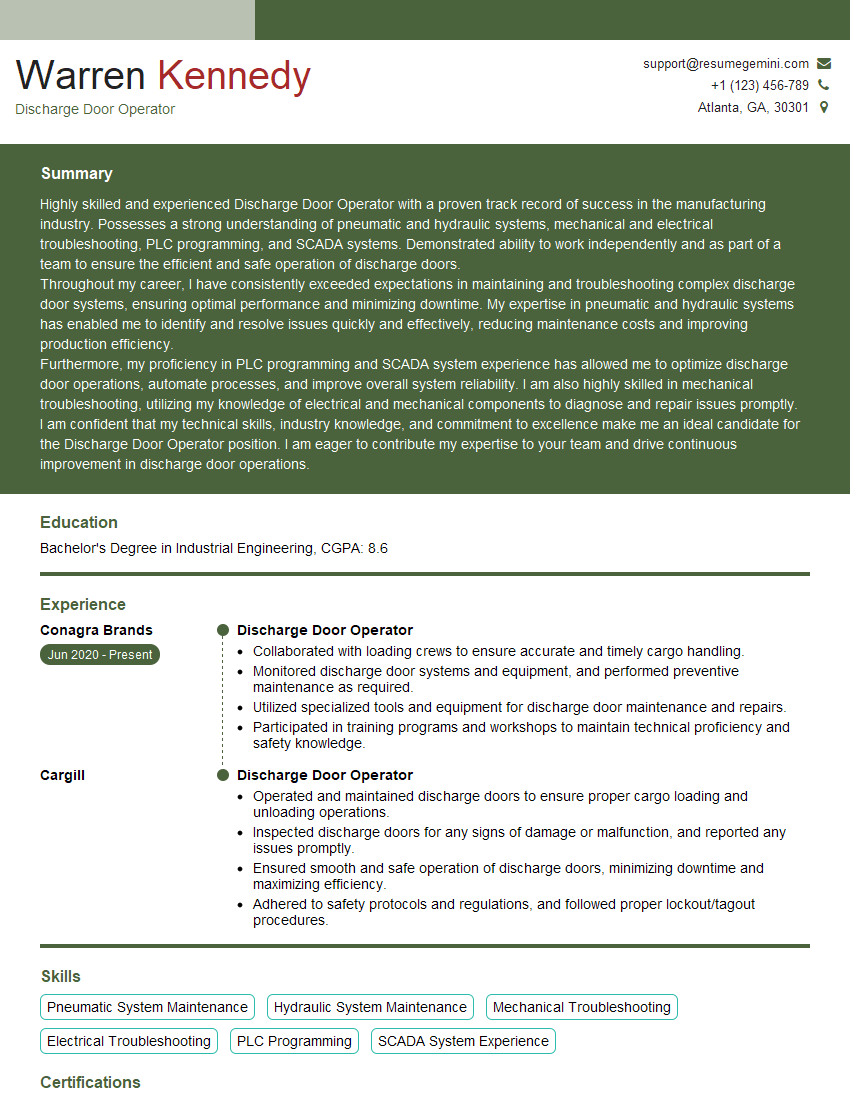

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Discharge Door Operator

1. Describe the role and responsibilities of a Discharge Door Operator in a bulk material handling system?

As a Discharge Door Operator, my primary responsibilities involve:

- Operating and monitoring discharge doors in bulk material handling systems

- Ensuring smooth and efficient discharge of materials

- Monitoring equipment performance and identifying potential issues

- Performing routine maintenance and troubleshooting to maintain optimal system function

- Communicating with other team members to coordinate operations and ensure safety

2. Explain the different types of discharge doors used in bulk material handling systems and their applications.

Mechanical Doors

- Slide Gates: Used to control the flow of material in vertical or horizontal chutes

- Butterfly Valves: Suitable for controlling large volumes of material

Pneumatic Doors

- Air Cannons: Utilized to dislodge or fluidize material buildup

- Vibratory Feeders: Provide consistent and controlled discharge of materials

3. Describe the key safety precautions that must be observed when operating discharge doors in bulk material handling systems.

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a hard hat

- Ensure that the system is properly grounded and all electrical connections are secure

- Never attempt to work on or adjust discharge doors while they are in operation

- Follow all established lockout/tagout procedures before performing maintenance or repairs

- Maintain a safe working distance from moving equipment and potential hazards

4. Explain the steps involved in troubleshooting common problems with discharge doors in bulk material handling systems.

- Identify the problem and its potential causes

- Visually inspect the discharge door for any visible damage or obstructions

- Check the electrical connections and ensure they are secure

- Test the discharge door operation manually to identify potential mechanical issues

- Refer to manufacturer’s documentation or consult with a qualified technician for further troubleshooting assistance

5. Describe the importance of proper maintenance and lubrication of discharge doors in bulk material handling systems.

Regular maintenance and lubrication are crucial for:

- Ensuring smooth and efficient operation of discharge doors

- Preventing premature wear and tear

- Extending the lifespan of the equipment

- Minimizing downtime and production losses

- Maintaining a safe and reliable working environment

6. Explain the different techniques used for discharging bulk materials from storage silos and hoppers.

- Gravity Flow: Utilizing the force of gravity to discharge materials from vertical silos

- Pneumatic Conveying: Employing air pressure to transport materials through pipelines

- Mechanical Conveying: Using mechanical devices such as screw conveyors or bucket elevators

- Vibration: Applying vibrations to break up cohesive materials and promote flow

- Fluidization: Injecting air into materials to create a fluid-like state, facilitating easier discharge

7. Describe the factors that influence the selection of discharge doors for bulk material handling systems.

- Type and properties of the materials being handled

- Flow rate and discharge capacity requirements

- Material flow characteristics (e.g., cohesive, abrasive, etc.)

- Compatibility with the existing handling system

- Space constraints and installation considerations

- Maintenance and operating costs

8. Explain the importance of minimizing material buildup and bridging in discharge doors of bulk material handling systems.

Material buildup and bridging can lead to:

- Reduced material flow and discharge efficiency

- Increased wear and tear on equipment

- Potential blockages and downtime

- Compromised product quality and consistency

- Safety hazards for operators

9. Describe the role of level sensors and indicators in discharge door operations and how they contribute to efficient material handling.

Level sensors and indicators provide:

- Real-time information on material levels in storage silos and hoppers

- Automatic activation and deactivation of discharge doors to maintain desired material levels

- Prevention of overfilling and underfilling, ensuring optimal discharge rates

- Early detection of potential material flow issues

- Improved safety by eliminating the need for manual level monitoring

10. Discuss the importance of following established operating procedures and safety protocols when working with discharge doors in bulk material handling systems.

Adhering to established procedures and safety protocols is crucial for:

- Ensuring the safety of operators and personnel

- Maintaining equipment reliability and efficiency

- Preventing accidents, injuries, and property damage

- Optimizing material handling operations and productivity

- Complying with industry regulations and standards

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Discharge Door Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Discharge Door Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Discharge Door Operator plays a crucial role in ensuring the smooth and efficient functioning of a loading bay or warehouse environment. Their primary responsibilities include:

1. Operating Discharge Doors

The operator is responsible for operating discharge doors using mechanical or electrical equipment.

- Ensure the doors open and close smoothly and safely.

- Monitor door sensors and safety devices to prevent accidents.

2. Inspecting and Maintaining Doors

To ensure optimal performance and safety, the operator must regularly inspect and maintain discharge doors.

- Inspect door panels, hinges, tracks, and seals for any damage or wear.

- Lubricate moving parts and replace worn components as needed.

3. Assisting with Loading and Unloading

The operator may assist with loading and unloading activities to ensure the timely and efficient movement of goods.

- Guide forklift operators through doorways.

- Ensure proper placement of goods on loading docks.

4. Following Safety Procedures

Maintaining a safe work environment is paramount, and the operator must adhere to established safety policies.

- Follow proper lockout/tagout procedures when servicing doors.

- Wear appropriate safety gear, such as high-visibility vests and hard hats.

Interview Preparation Tips

To ace an interview for a Discharge Door Operator position, candidates should thoroughly prepare and demonstrate their skills and knowledge. Here are some essential interview tips:

1. Research the Company and Role

Research the company’s industry, operations, and specific requirements for the position. This will help you tailor your answers to the interviewer’s questions.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating discharge doors, as well as any knowledge of door maintenance and safety procedures. If you have worked in a similar role, highlight your accomplishments and responsibilities.

3. Prepare for Technical Questions

Interviewers may ask technical questions about discharge doors. Be prepared to discuss different types of doors, their components, and troubleshooting techniques.

4. Showcase Your Physical Abilities

The position requires physical stamina and the ability to work in a fast-paced environment. Mention any relevant work experience or physical activities that demonstrate your fitness.

5. Ask Informed Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest. Prepare a few questions about the company, the role, or the industry.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Discharge Door Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Discharge Door Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.