Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Disintegrator Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

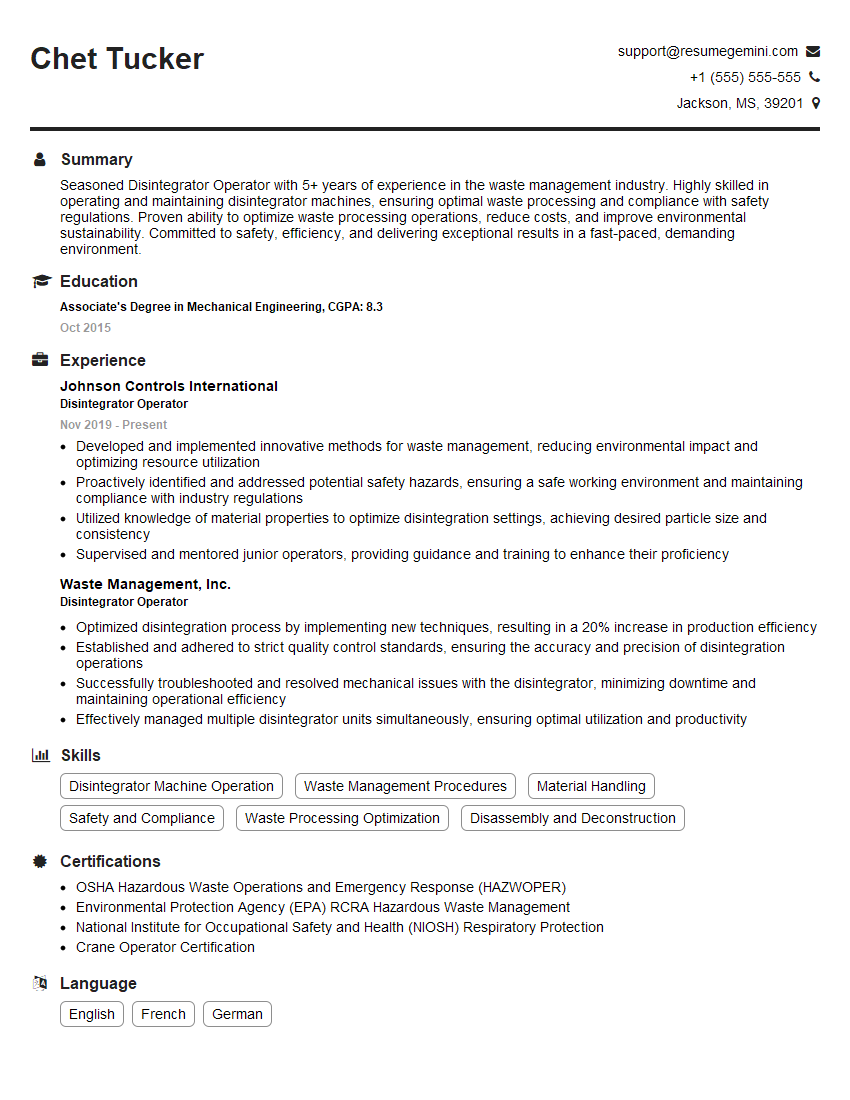

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Disintegrator Operator

1. Describe the proper procedure for operating a disintegrator?

The proper procedure for operating a disintegrator involves the following steps:

- Inspect the disintegrator prior to operation to ensure it is in good working order.

- Ensure the disintegrator is properly grounded to prevent electrical hazards.

- Wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection.

- Load the material to be disintegrated into the disintegrator’s chamber.

- Close the disintegrator’s chamber and secure it.

- Start the disintegrator and allow it to run until the material is sufficiently disintegrated.

- Stop the disintegrator and open the chamber.

- Remove the disintegrated material from the chamber.

- Clean the disintegrator’s chamber and blades to remove any residual material.

2. What are the different types of disintegrators and their applications?

Types of Disintegrators

- Hammer Mills: Used for coarse grinding of hard materials like wood chips, plastics, and metals.

- Pin Mills: Suitable for fine grinding of soft materials like chemicals, pharmaceuticals, and food products.

- Cage Mills: Used for medium-fine grinding of friable materials like ceramics, glass, and minerals.

- Fluidized Bed Jet Mills: Ideal for ultra-fine grinding of materials sensitive to heat or contamination.

Applications

- Reclamation of waste materials

- Size reduction for further processing

- Preparation of feed for animals and poultry

- Manufacturing of paints, coatings, and pharmaceuticals

3. How do you troubleshoot common problems encountered when operating a disintegrator?

Here are some common troubleshooting tips for disintegrator operation:

- Overheating: Check for blocked air vents, excessive material feed, or worn bearings.

- Vibration: Inspect for loose bolts, unbalanced rotors, or misalignment of components.

- Reduced efficiency: Clean or replace worn blades, inspect for blockages in the feed system, and ensure proper screen size.

- Excessive noise: Check for damaged bearings, worn gears, or loose panels.

- Electrical issues: Inspect wiring, connections, and motor for any faults or short circuits.

4. What are the safety precautions that should be followed when working with a disintegrator?

To ensure safety when operating a disintegrator, it is crucial to follow these precautions:

- Wear appropriate protective gear, including safety glasses, gloves, hearing protection, and a dust mask.

- Inspect the disintegrator regularly to ensure it is in good working condition.

- Ground the disintegrator to prevent electrical hazards.

- Lock out and tag out the disintegrator before performing any maintenance or repairs.

- Avoid operating the disintegrator in explosive or flammable environments.

- Keep the work area clean and free of debris to prevent tripping hazards.

5. How do you determine the appropriate operating parameters for a disintegrator based on the material being processed?

To determine the optimal operating parameters for a disintegrator based on the material being processed, consider the following factors:

- Material characteristics: Hardness, particle size, moisture content, and abrasiveness.

- Desired end product: Particle size, shape, and distribution.

- Type of disintegrator: Hammer mill, pin mill, cage mill, etc.

- Manufacturer’s recommendations: Refer to the disintegrator’s manual for specific guidelines.

6. What maintenance procedures are required to keep a disintegrator in optimal operating condition?

Regular maintenance is crucial to ensure the longevity and optimal performance of a disintegrator:

- Daily: Inspect for loose or damaged parts, clean screens, and lubricate bearings.

- Weekly: Check belts for tension and wear, clean dust collectors, and inspect electrical connections.

- Monthly: Replace worn blades or screens, check rotor alignment, and inspect for any unusual noises or vibrations.

- Quarterly: Perform a thorough inspection, including disassembly and cleaning, and replace any necessary components.

- Annually: Conduct preventive maintenance, including major overhauls and replacement of critical parts.

7. How do you handle and dispose of hazardous materials produced by the disintegrator?

When handling and disposing of hazardous materials produced by the disintegrator, follow these guidelines:

- Identify the hazardous materials and their specific disposal requirements.

- Use appropriate personal protective equipment, including respirators, gloves, and protective clothing.

- Store hazardous materials in designated, appropriately labeled containers.

- Dispose of hazardous materials through licensed waste disposal companies.

- Comply with all applicable environmental regulations and safety standards.

8. What is the role of the disintegrator in the overall production process?

The disintegrator plays a vital role in the overall production process by:

- Reducing the size of materials to the desired specifications.

- Preparing materials for further processing, such as blending, mixing, or chemical reactions.

- Improving the efficiency and effectiveness of downstream processes.

- Facilitating the handling, storage, and transportation of materials.

- Creating a more uniform and consistent product.

9. How do you maintain the accuracy and consistency of the disintegrated product?

To maintain accuracy and consistency in the disintegrated product, follow these practices:

- Calibrate the disintegrator regularly using standard materials.

- Monitor and adjust operating parameters (e.g., speed, feed rate) to achieve the desired particle size.

- Use screens with appropriate mesh sizes to ensure the desired particle size distribution.

- Inspect the disintegrated product for uniformity and consistency.

- Implement quality control measures, such as sampling and testing, to verify product specifications.

10. What are the challenges you have faced while operating a disintegrator and how did you overcome them?

Some challenges I have faced while operating a disintegrator include:

- Equipment malfunctions: Troubleshooting and resolving issues such as overheating, vibration, or electrical problems.

- Material handling: Managing the feeding and discharge of materials to ensure efficient operation.

- Safety concerns: Adhering to safety protocols, handling hazardous materials, and minimizing dust generation.

- Product quality control: Maintaining the accuracy and consistency of the disintegrated product.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Disintegrator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Disintegrator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Disintegrator Operator plays a crucial role in the smooth functioning of the organization’s manufacturing operations. Their primary responsibilities involve:

1. Disintegration Process Supervision

Meticulously monitoring and controlling the disintegration process to ensure adherence to established standards and specifications.

- Diligently observing equipment performance, feed rates, and product quality.

- Promptly identifying any deviations from standard operating procedures and implementing corrective actions.

2. Equipment Operation and Maintenance

Ensuring efficient operation and upkeep of disintegration equipment to optimize productivity.

- Skilled in operating disintegrators, conveyors, and ancillary machinery.

- Conducting regular inspections, cleaning, and minor repairs to maintain equipment functionality.

3. Production Monitoring and Reporting

Maintaining accurate records and reporting on production quantities, quality control data, and equipment performance.

- Documenting production logs, downtime incidents, and equipment maintenance schedules.

- Providing timely reports to supervisors and management for performance assessment.

4. Quality Assurance

Vigilantly monitoring product quality to ensure compliance with customer specifications and industry standards.

- Sampling and testing products at various stages of the disintegration process.

- Implementing corrective actions to address any quality deviations.

Interview Tips

Preparing thoroughly for a Disintegrator Operator interview can significantly enhance your chances of success. Consider the following tips:

1. Research the Company and Role

Acquire a comprehensive understanding of the company’s operations, industry, and the specific responsibilities of the Disintegrator Operator position.

- Visit the company’s website, LinkedIn page, and industry-specific publications.

- Thoroughly review the job description, noting key requirements and expectations.

2. Highlight Relevant Experience and Skills

Articulate your relevant experience and skills that align with the job requirements. Emphasize your:

- Proficiency in operating disintegrators and associated equipment.

- Understanding of disintegration processes and quality control procedures.

- Ability to maintain accurate records and report on production and quality.

3. Prepare for Technical Questions

Be prepared to answer questions related to the technical aspects of the job, such as:

- Describe the principles of disintegration and its applications.

- Explain the maintenance procedures for disintegrators and associated equipment.

- Discuss the quality control measures implemented in the disintegration process.

4. Practice Your Answers

Prepare thoughtful answers to common interview questions. This includes questions about your:

- Career goals and motivations.

- Strengths and weaknesses.

- Availability and flexibility.

5. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately for the interview and arrive on time to demonstrate your professionalism and respect for the hiring team.

- Consider wearing a suit or business casual attire.

- Allow ample time for transportation and parking to avoid any delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Disintegrator Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!