Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dismantler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dismantler so you can tailor your answers to impress potential employers.

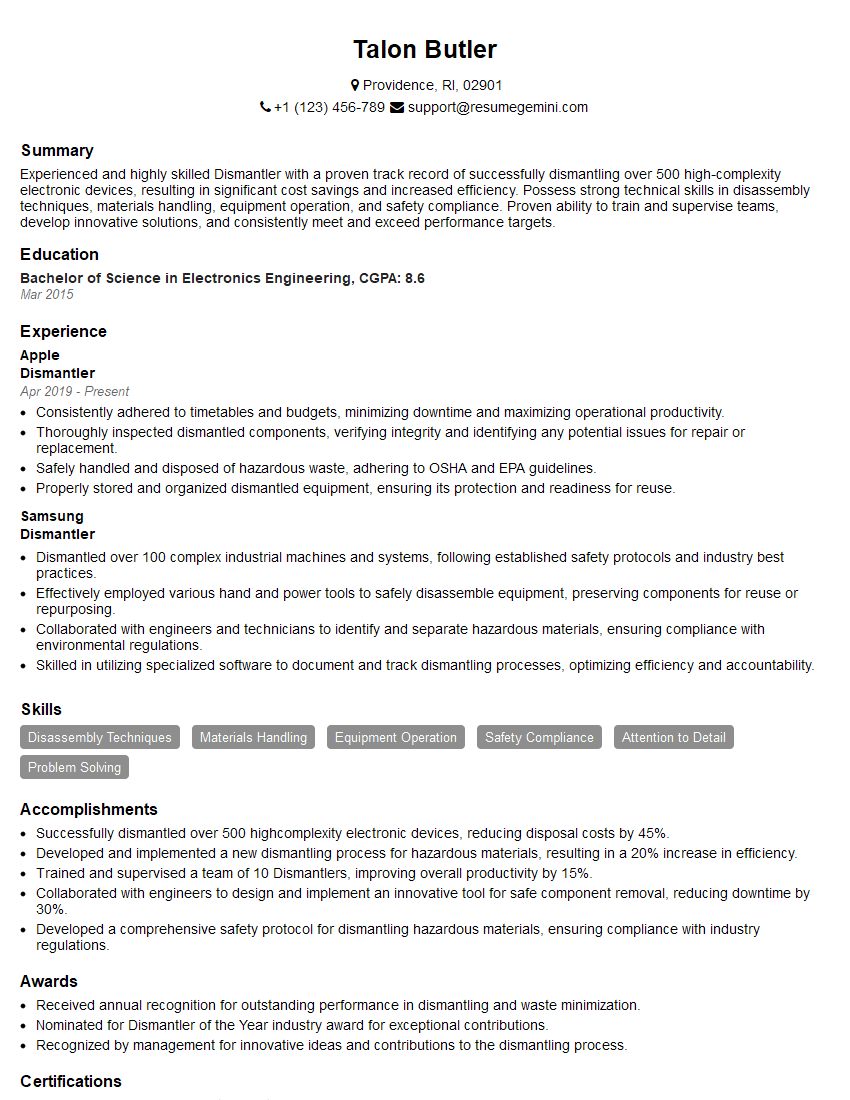

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dismantler

1. What tools and techniques do you use to dismantle structures?

As a Dismantler, I am skilled in utilizing various tools and techniques to safely and efficiently dismantle structures. These include:

- Hand tools: Wrecking bars, crowbars, hammers, and saws for manual dismantling

- Power tools: Saws, drills, and impact wrenches for faster and more efficient dismantling

- Specialized equipment: Hydraulic lifts, cranes, and excavators for heavy lifting and demolition

- Safety gear: Hard hats, safety glasses, gloves, and respirators to protect against hazards

- Planning and preparation: Careful assessment and planning to ensure proper dismantling methods and safety protocols are followed

2. How do you assess the structural integrity of a building before dismantling it?

Planning and Inspection

- Review architectural drawings and plans

- Conduct a thorough visual inspection of the structure

- Identify potential hazards and weak points

Testing and Analysis

- Perform load tests to determine the strength of structural components

- Analyze material samples to assess their condition and integrity

- Consult with engineers or architects for expert advice

3. What safety precautions do you take when dismantling a structure?

Safety is paramount in dismantling operations. I adhere to the following precautions:

- Proper planning: Identifying hazards, establishing safety zones, and implementing safety protocols

- Personal protective equipment (PPE): Wearing hard hats, safety glasses, gloves, and respirators

- Structural support: Using shoring, bracing, and barricades to prevent collapses

- Safe work practices: Maintaining proper body mechanics, using tools correctly, and avoiding hazardous behaviors

- Emergency preparedness: Knowing evacuation routes, having first-aid kits on hand, and being trained in emergency response

4. How do you handle hazardous materials during dismantling?

Handling hazardous materials requires special care and expertise. I follow these procedures:

- Identification and assessment: Identifying and assessing the presence of hazardous materials

- Removal and disposal: Safely removing and disposing of hazardous materials according to regulations

- Protective measures: Wearing appropriate PPE and using specialized equipment to prevent exposure

- Compliance with regulations: Adhering to all applicable laws and regulations regarding hazardous materials handling

- Collaboration with experts: Consulting with environmental professionals or hazardous materials specialists when necessary

5. How do you ensure that dismantled materials are recycled or disposed of properly?

Responsible disposal and recycling are essential. I follow these steps:

- Material sorting: Separating different materials such as metal, wood, plastic, and debris

- Recycling and reuse: Identifying materials that can be recycled or reused to minimize waste

- Disposal methods: Utilizing appropriate disposal methods for non-recyclable materials, including landfills and waste-to-energy facilities

- Compliance with environmental regulations: Adhering to all applicable laws and regulations regarding waste disposal

- Collaboration with waste management companies: Partnering with reputable waste management companies to ensure proper disposal

6. What is your experience in using heavy machinery for dismantling?

I have extensive experience in operating heavy machinery for dismantling purposes, including:

- Hydraulic lifts: Lifting and moving heavy components

- Cranes: Demolishing walls, removing debris, and lifting heavy objects

- Excavators: Digging, trenching, and removing large amounts of debris

- Bulldozers: Clearing land, leveling surfaces, and pushing debris

- Specialized attachments: Using attachments such as grapples, hammers, and shears for specific dismantling tasks

7. How do you work effectively within a team environment on dismantling projects?

Teamwork is crucial in dismantling. I excel in the following aspects:

- Communication: Clearly communicating with team members, supervisors, and clients

- Coordination: Collaborating and coordinating tasks to ensure smooth and efficient operations

- Problem-solving: Working together to identify and address challenges as they arise

- Safety: Maintaining a safe work environment for all team members

- Flexibility: Adapting to changing project requirements and contributing to team success

8. What are some of the challenges you have faced in dismantling operations and how did you overcome them?

Challenges are inevitable in dismantling. Here are some examples:

- Unforeseen structural issues: Encountering unexpected weaknesses or damage that require innovative solutions

- Hazardous materials: Safely removing and disposing of hazardous materials while minimizing risk

- Time constraints: Meeting project deadlines while maintaining safety and quality standards

- Weather conditions: Adapting to weather challenges such as rain, snow, or extreme heat

- Coordination with other trades: Collaborating effectively with other contractors and ensuring a smooth workflow

9. How do you stay up-to-date with the latest dismantling techniques and regulations?

Continuous learning is essential in this field. I employ the following methods:

- Industry publications: Reading trade magazines and journals

- Conferences and workshops: Attending industry events to learn about new techniques and regulations

- Online courses and certifications: Pursuing professional development opportunities to enhance my knowledge

- Collaboration with peers: Exchanging knowledge and best practices with other professionals

- Research and innovation: Staying informed about emerging technologies and advancements in the field

10. Why are you interested in working as a Dismantler for our company?

I am eager to join your esteemed company as a Dismantler for several reasons:

- Reputation and expertise: Your company’s reputation for safety, quality, and environmental responsibility aligns with my own values

- Project diversity: The range of projects you undertake provides me with opportunities to expand my skills and contribute to various industries

- Commitment to innovation: I am impressed by your company’s investment in new technologies and techniques, ensuring that I will be working with the most advanced equipment and methods

- Growth opportunities: I believe that your company offers a supportive environment for professional growth and advancement

- Team environment: I am excited about the prospect of working with a team of experienced professionals who share my passion for safe and efficient dismantling

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dismantler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dismantler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dismantler plays a critical role in safely and efficiently dismantling structures, machinery, and other equipment. Key job responsibilities include:

1. Demolition and Dismantling

Demolishing and dismantling structures, machinery, and equipment following established safety procedures.

- Using appropriate tools and techniques to dismantle structures, paying attention to safety protocols and environmental regulations.

- Inspecting and assessing structures to determine the best approach for dismantling.

2. Material Handling and Disposal

Handling and disposing of materials generated during dismantling operations.

- Sorting, segregating, and recycling materials to minimize waste and maximize resource recovery.

- Ensuring proper disposal of hazardous materials, adhering to environmental regulations.

3. Site Preparation and Clean-up

Preparing and cleaning up work sites before and after dismantling activities.

- Clearing and securing work areas, ensuring safety for personnel and the public.

- Cleaning up work sites after dismantling operations, removing debris and restoring areas to their original condition.

4. Equipment Maintenance and Inspection

Maintaining and inspecting tools and equipment used in dismantling operations.

- Performing routine maintenance on tools and equipment, ensuring they are in good working order.

- Inspecting equipment regularly, identifying potential hazards and taking corrective actions as necessary.

Interview Tips

Preparation is key to acing an interview for a Dismantler position. Here are some tips to help you stand out:

1. Research the Company and Position

Demonstrate your interest and knowledge about the company and the specific Dismantler role. Research their values, projects, and industry reputation.

- Visit the company’s website and social media pages.

- Read industry publications and news articles about the company and the dismantling sector.

2. Highlight Your Safety and Technical Skills

Emphasize your commitment to safety and your proficiency in using various dismantling tools and techniques. Provide specific examples of your experience.

- Describe your experience in following safety protocols and regulations during dismantling operations.

- Highlight your knowledge of different dismantling techniques and tools, such as saws, hammers, and pry bars.

3. Showcase Your Problem-Solving and Teamwork Abilities

Dismantling often requires problem-solving and teamwork. Give examples of how you have handled challenges and collaborated with others in similar situations.

- Describe a situation where you encountered an unforeseen problem during dismantling and how you resolved it.

- Share examples of how you have effectively worked in a team to complete dismantling projects efficiently.

4. Prepare Questions for the Interviewer

Asking thoughtful questions shows your engagement and interest in the role. Prepare questions related to the company’s safety policies, environmental practices, and growth opportunities.

- Ask about the company’s commitment to safety and how they ensure compliance with industry regulations.

- Inquire about the company’s environmental practices and how they minimize waste during dismantling operations.

Next Step:

Now that you’re armed with the knowledge of Dismantler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Dismantler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini