Feeling lost in a sea of interview questions? Landed that dream interview for Dispenser Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Dispenser Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

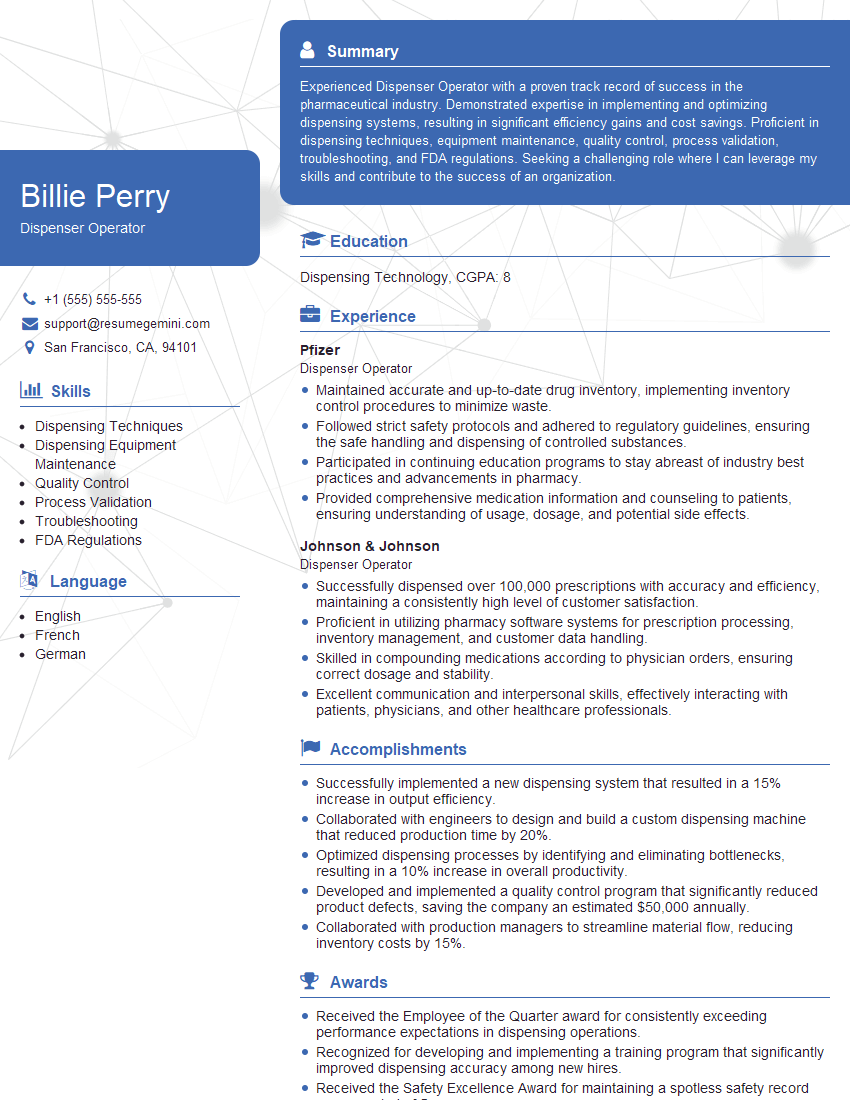

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dispenser Operator

1. Describe the key responsibilities of a Dispenser Operator.

As a Dispenser Operator, I would be responsible for operating and maintaining dispensing equipment, ensuring accurate and consistent dispensing of products. My duties would involve:

- Setting up and calibrating dispensing equipment

- Monitoring and maintaining dispensing parameters

- Troubleshooting and resolving any operational issues

- Ensuring compliance with safety regulations and quality standards

- Maintaining a clean and organized work area

2. Explain the different types of dispensing equipment you have experience using.

Volumetric Dispensers

- Positive displacement pumps

- Time/pressure dispensers

Non-Volumetric Dispensers

- Jet valves

- Spray valves

3. How do you ensure accurate and consistent dispensing of products?

To ensure accuracy and consistency, I follow a rigorous process that includes:

- Calibrating equipment regularly using certified standards

- Monitoring dispensing parameters, such as pressure, temperature, and flow rate

- Inspecting products for defects or variations

- Implementing statistical process control techniques to identify and eliminate sources of variation

- Following established operating procedures and adhering to quality standards

4. What are the common troubleshooting issues you encounter in dispensing operations? How do you resolve them?

Common troubleshooting issues I have encountered include:

- Clogged nozzles: I clear blockages using solvents or ultrasonic cleaning.

- Faulty valves: I inspect valves for damage and replace them if necessary.

- Inconsistent flow rates: I check pressure regulators and tubing for leaks or restrictions.

- Dispensing errors: I analyze data to identify the root cause and implement corrective actions.

5. How do you maintain and clean dispensing equipment to ensure optimal performance?

To maintain optimal performance, I follow a comprehensive equipment maintenance program, which includes:

- Regular cleaning and inspection of equipment components

- Lubrication of moving parts

- Replacement of worn or damaged parts

- Calibration and verification of equipment performance

- Adherence to manufacturer’s maintenance guidelines

6. What safety precautions do you take when working with dispensing equipment?

I prioritize safety in all aspects of my work:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat

- Following established safety protocols for handling chemicals or hazardous materials

- Ensuring equipment is properly grounded and electrically safe

- Maintaining a clean and organized work area

- Receiving proper training on equipment operation and safety procedures

7. How do you ensure compliance with quality standards and regulatory requirements?

Compliance is of utmost importance to me:

- Adhering to established quality standards, such as ISO 9001 or industry-specific regulations

- Implementing quality control measures, such as inspections and testing

- Maintaining documentation and records of all dispensing operations

- Participating in internal audits and external certifications

- Staying updated on industry best practices and regulatory changes

8. How do you stay up-to-date with advancements in dispensing technology?

To stay current, I actively:

- Attend industry conferences and workshops

- Read technical publications and journals

- Participate in online forums and discussions

- Collaborate with experts and peers

- Seek opportunities for professional development

9. Describe a situation where you successfully resolved a complex dispensing issue.

In a previous role, we encountered an issue with inconsistent dispensing accuracy. I conducted a thorough investigation, analyzed data from the dispensing equipment, and identified a faulty sensor. By replacing the sensor and recalibrating the equipment, I was able to restore accuracy and minimize product waste.

10. How do you prioritize tasks and manage your time effectively in a fast-paced production environment?

Prioritization and time management are crucial. I:

- Assess the urgency and importance of tasks

- Create a daily or weekly schedule

- Delegate responsibilities when possible

- Use technology to streamline tasks

- Communicate effectively with colleagues to avoid bottlenecks

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dispenser Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dispenser Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dispenser Operators are accountable for setting up and operating dispensing equipment, to manufacture different products. They monitor the production process, ensuring that the equipment functions correctly, and products meet quality standards.

1. Equipment Setup and Operation

An employee in this role is responsible for the following duties:

- Set up and calibrate dispensing equipment, according to product specifications

- Monitor the equipment during operation, ensuring it functions properly

2. Production Monitoring

To ensure efficient production, the incumbent must:

- Monitor production flow, to identify and address any issues promptly

- Inspect products for defects, and take corrective action as necessary

3. Quality Assurance

The employee will be responsible for:

- Adhering to quality control standards, to ensure products meet specifications

- Conducting product testing, to verify compliance with quality requirements

4. Maintenance and Troubleshooting

The incumbent will be required to perform the following:

- Perform routine maintenance on dispensing equipment, to ensure optimal performance

- Troubleshoot and resolve equipment malfunctions, to minimize downtime

Interview Tips

To prepare effectively for a Dispenser Operator interview, consider the following tips:

1. Research the Company and Role

By researching the company and the specific role, you can tailor your answers to align with their needs and expectations.

- Visit the company website to learn about their products, values, and industry standing.

- Carefully review the job description to grasp the specific responsibilities and requirements of the role.

2. Highlight Relevant Experience and Skills

During the interview, focus on showcasing your experience and skills that directly relate to the job requirements. Use specific examples to demonstrate your abilities.

- Emphasize your experience in operating and maintaining dispensing equipment.

- Highlight your knowledge of quality control standards and your commitment to delivering high-quality products.

- Provide examples of your ability to troubleshoot and resolve equipment issues.

3. Prepare for Common Interview Questions

Familiarize yourself with common interview questions and prepare thoughtful responses that showcase your qualifications and enthusiasm for the role.

- Tell me about your experience in operating and maintaining dispensing equipment.

- How do you ensure that products meet quality specifications?

- Describe a time when you had to troubleshoot and resolve a complex equipment issue.

4. Practice Your Answers

Practice answering interview questions aloud to become more comfortable and confident during the actual interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Ask a friend or family member to conduct a mock interview to provide feedback and support.

5. Dress Professionally and Arrive Punctually

First impressions matter, so dress professionally and arrive for the interview on time. This demonstrates respect for the interviewer and the company.

- Choose business attire that is clean, pressed, and appropriate for the industry.

- Plan your route in advance to avoid being late and allow for any unexpected delays.

Next Step:

Now that you’re armed with the knowledge of Dispenser Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Dispenser Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini