Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Display Fabricator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Display Fabricator so you can tailor your answers to impress potential employers.

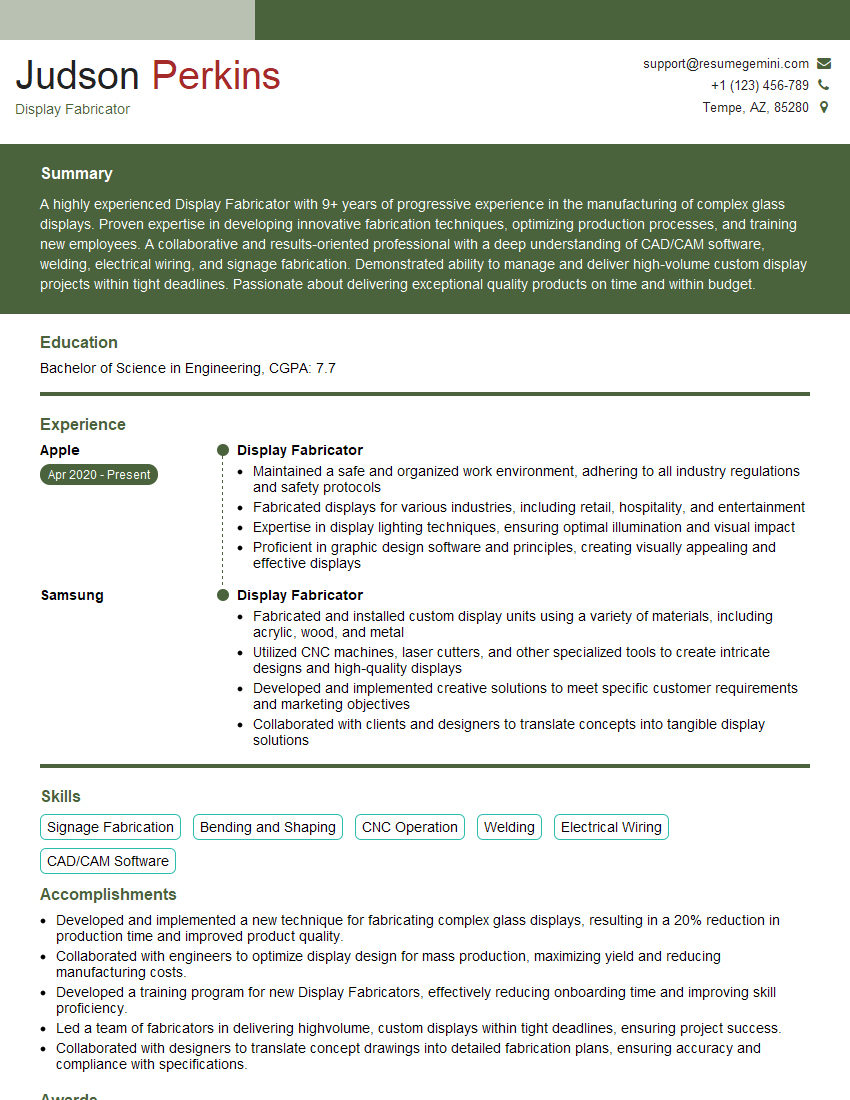

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Display Fabricator

1. Describe the key steps involved in creating a custom display fabric?

The key steps involved in creating a custom display fabric are:

- Design: Create the design, including the layout, colors, and any special features.

- Printing: Print the design onto the fabric using a specialized printing process.

- Finishing: Apply any finishing touches to the fabric, such as laminating, coating, or flame retardant treatment.

2. What factors should be considered when selecting materials for a display fabric?

- Usage: The intended use of the fabric, such as indoor or outdoor, display or advertising.

- Durability: The strength and longevity of the fabric, especially if it is exposed to high traffic or outdoor elements.

- Visual impact: The fabric’s color, texture, and drape should complement the design and enhance the visual appeal.

- Cost: The budget available for the project and the cost-effectiveness of different materials.

3. Explain the different techniques used for printing designs onto display fabrics.

- Digital printing: Uses inkjet technology to print high-resolution images and designs directly onto the fabric.

- Screen printing: Involves forcing ink through a stencil onto the fabric, resulting in bold and vibrant colors.

- Sublimation printing: Embeds dyes into the fabric fibers using heat and pressure, creating durable and long-lasting prints.

4. Describe the process of laminating a display fabric and its benefits.

Laminating a display fabric involves applying a thin layer of protective material, such as PVC, to the fabric.

- Benefits:

- Increased durability and weather resistance.

- Improved tear and scratch resistance.

- Enhanced visual appeal with a glossy or matte finish.

5. What are the different types of flame retardant treatments available for display fabrics?

- Inherent flame retardant: Fabrics treated with chemicals that make them naturally flame resistant.

- Topical flame retardant: Chemical coatings or sprays applied to the fabric to provide flame resistance.

- Barrier flame retardant: Fabrics with a fire-resistant coating or lining that prevents flame spread.

6. Explain the importance of color matching in display fabric production.

- Ensures consistency throughout the production process.

- Maintains brand identity and aesthetic accuracy.

- Avoids color variations and mismatches in finished products.

7. Describe the quality control measures used to ensure the quality of display fabrics.

- Material testing: Checks the strength, durability, and other properties of the fabric.

- Printing accuracy: Ensures that designs are printed correctly and meet specifications.

- Color matching: Verifies that colors match the intended design and samples.

- Finish and appearance: Inspects the fabric for defects, blemishes, or uneven finishes.

8. Explain the importance of environmental sustainability in display fabric production.

- Reduces waste and pollution.

- Conserves resources and energy.

- Promotes ethical and responsible manufacturing practices.

- Meets growing consumer demand for sustainable products.

9. Describe the trends in display fabric technology and how they are impacting the industry.

- Digital printing advancements: Enabling high-definition and customized prints.

- Innovative materials: Development of fabrics with unique textures, properties, and sustainability features.

- Automation and efficiency: Enhancing production speed and reducing costs.

- Data-driven insights: Using analytics to optimize design, production, and marketing.

10. What are your strengths and weaknesses as a Display Fabricator?

Strengths:

- Expertise in various display fabric printing techniques

- Strong knowledge of materials and their properties

- Attention to detail and commitment to quality

Weaknesses:

- Limited experience in certain specialized fabrications

- Working under tight deadlines can be challenging (but I am continuously working on improving my time management skills)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Display Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Display Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Display Fabricators are responsible for creating and constructing customized displays for various purposes, including marketing campaigns, trade shows, and retail environments.

1. Design and Planning

Collaborate with designers and clients to develop display concepts, ensuring that they meet design specifications, budget constraints, and project timelines.

2. Fabrication and Assembly

Use a variety of materials and techniques to construct displays, including wood, metal, plastics, and fabrics. Assemble and install displays according to blueprints and specifications.

3. Finishing and Graphics

Apply paint, graphics, and other finishes to enhance the visual appeal and durability of displays. Ensure that all graphics and branding elements are accurate and consistent with client requirements.

4. Installation and Maintenance

Install displays at designated locations, ensuring proper placement and functionality. Perform ongoing maintenance and repairs to keep displays in optimal condition.

Interview Tips

Preparing for an interview as a Display Fabricator requires careful consideration of your skills, experience, and the specific requirements of the role. Here are some tips to help you ace your interview:

1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and services. Research the specific job description to gain insights into the essential responsibilities and qualifications.

- Example: Visit the company’s website and LinkedIn page to gather information about their business and culture.

2. Showcase Your Portfolio

Bring a portfolio of your previous work to the interview, either in physical or digital form. It should include a variety of display projects that demonstrate your skills in design, fabrication, and finishing.

- Example: Highlight projects that showcase your ability to work with different materials, create innovative designs, and meet client expectations.

3. Emphasize Your Technical Skills

Discuss your proficiency in fabrication techniques, such as carpentry, welding, and painting. Mention any relevant certifications or training that you have obtained.

- Example: Explain how your experience in using specialized tools and equipment enables you to execute complex display designs.

4. Highlight Your Customer Service Abilities

Display Fabricators often work closely with clients, so it’s important to demonstrate your customer service skills.

- Example: Share instances where you successfully communicated with clients to understand their needs, resolve issues, and ensure satisfaction.

5. Prepare Questions

Come prepared with thoughtful questions for the interviewer. This shows your interest in the role and the company, and it gives you an opportunity to clarify any aspects of the position or organization.

- Example: Ask about the company’s growth plans, the team structure, or the opportunities for professional development.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Display Fabricator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Display Fabricator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.