Are you gearing up for an interview for a Display Screen Fabricator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Display Screen Fabricator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

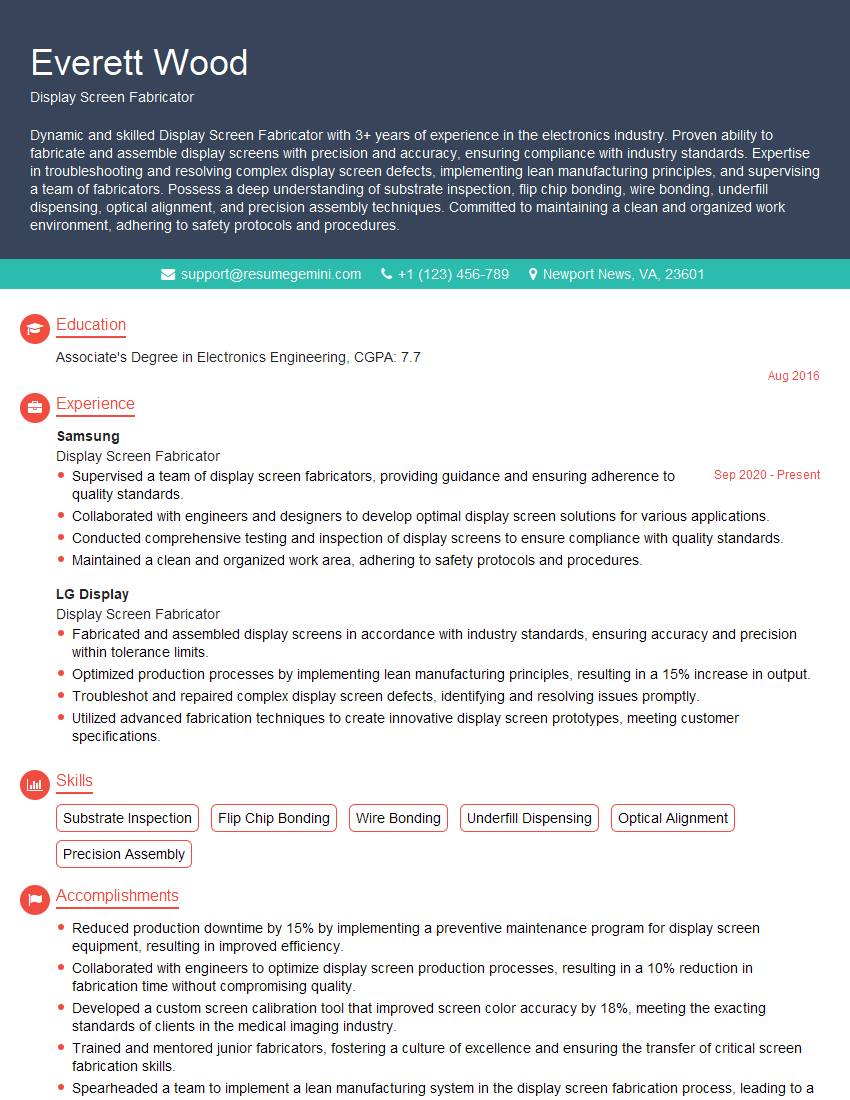

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Display Screen Fabricator

1. What are the different types of display screens used in the industry and what are their key characteristics?

Answer

- Liquid Crystal Display (LCD) – Thin, lightweight, energy-efficient, offers good image quality.

- Organic Light-Emitting Diode (OLED) – Self-illuminating, provides high contrast ratios, wide color gamut, and fast response times.

- Plasma Display Panel (PDP) – Produces vibrant colors, high brightness, and wide viewing angles, but consumes more energy than LCD and OLED.

- Electron Beam (EB) Display – High-resolution, provides excellent color accuracy and sharpness, used in high-end applications.

- Field Emission Display (FED) – Similar to EB but uses field emission instead of electron beam, offering potential for thinner and more flexible displays.

2. Describe the process of fabricating a display screen, from raw materials to finished product.

Answer

: Raw Material Preparation

- Selection and purification of materials such as glass, chemicals, and semiconductors.

- Creation of thin glass substrates for the display.

Subheading: Panel Formation

- Coating the glass substrates with transparent conductive films (TCFs).

- Applying liquid crystal or organic material layers.

- Patterned deposition of electrodes.

Subheading: Backlight Integration

- Incorporation of LED or CCFL backlight modules.

- Calibration of backlight brightness and color temperature.

Subheading: Assembly and Finishing

- Joining the front and back panels.

- Quality control and testing.

- Encapsulation and packaging.

3. What are the critical quality control parameters in display screen fabrication?

Answer

- Pixel density and resolution – Ensuring sharpness and detail.

- Color accuracy – Maintaining consistent and accurate color reproduction.

- Brightness and contrast – Optimizing visibility and image quality.

- Viewing angle – Ensuring a wide and distortion-free viewing experience.

- Response time – Measuring the speed of pixel switching, which affects motion blur.

- Uniformity – Ensuring consistent brightness and color across the entire display.

- Durability – Testing for resistance to scratches, impact, and environmental factors.

4. Explain the different methods used to optimize display performance, such as image processing, color calibration, and anti-glare coatings.

Answer

Subheading: Image Processing

- Sharpening and noise reduction algorithms to enhance image clarity.

- Motion interpolation to improve smoothness of moving images.

Subheading: Color Calibration

- Adjustment of red, green, blue (RGB) channels to ensure accurate color reproduction.

- Calibration using specialized tools and software to meet industry standards.

Subheading: Anti-Glare Coatings

- Application of thin-film coatings to reduce reflections and improve visibility in bright environments.

- Various techniques such as chemical etching, physical vapor deposition (PVD), and nano-particle dispersion.

5. Describe the emerging trends in display technology, such as flexible display panels, virtual reality (VR), and augmented reality (AR).

Answer

- Flexible Display Panels – Lightweight, bendable, and shatter-resistant displays suitable for wearable devices and foldable smartphones.

- Virtual Reality (VR) – Immersive 3D experiences using head-mounted displays (HMDs) that track head movements.

- Augmented Reality (AR) – Superimposition of digital information onto the real world viewed through transparent displays or smart glasses.

6. What is the role of machine vision and automation in display screen fabrication?

Answer

- Machine Vision – Inspection and analysis of display panels for defects, alignment errors, and other quality issues.

- Automation – Use of robots and automated assembly lines to improve productivity, consistency, and reduce human error.

- Integration of Machine Vision and Automation – Automated defect detection and correction, resulting in higher yields and reduced production costs.

7. Discuss the environmental impact of display screen manufacturing and disposal, and measures taken to minimize it.

Answer

Subheading: Environmental Impact

- Generation of hazardous waste from chemicals and solvents used in fabrication.

- Disposal of electronic waste (e-waste) from discarded displays.

Subheading: Minimization Measures

- Use of eco-friendly materials and processes.

- Recycling and disposal programs for e-waste.

- Design for longevity and repairability.

8. How do you stay updated with the latest advancements in display screen technology?

Answer

- Attending industry conferences and exhibitions.

- Reading technical journals and research papers.

- Engaging in online forums and discussions.

- Networking with professionals in the field.

9. Describe a specific project or achievement in display screen fabrication that you are particularly proud of.

Answer

- Developed and implemented a new process for fabricating high-resolution LCD panels with reduced pixel defects.

- Collaborated with a team to design and produce a flexible OLED display for a wearable device.

- Led a project to improve the color accuracy and viewing angle of a plasma display panel.

10. Why are you interested in joining our company as a Display Screen Fabricator?

Answer

- Impressed by the company’s reputation in the display industry.

- Excited about the opportunity to contribute to the development of cutting-edge display technologies.

- Passionate about solving technical challenges and delivering high-quality products.

- Belief that my skills and experience align well with the company’s goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Display Screen Fabricator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Display Screen Fabricator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Display Screen Fabricators play a crucial role in the production of high-quality display screens, including those used in TVs, laptops, and smartphones. Their key responsibilities encompass a wide range of tasks related to fabricating and assembling display screens.

1. Fabricating Display Screen Components

Fabricators are responsible for creating the individual components that make up a display screen. This may include cutting, shaping, and assembling various materials like glass, plastic, and metal.

- Cutting and shaping display screen panels

- Assembling display screen frames and enclosures

2. Display Screen Assembly

Once the components are fabricated, fabricators assemble them to create the complete display screen. This involves connecting electrical components, attaching the screen to a backlight, and ensuring proper alignment.

- Assembling display screens with precision and accuracy

- Testing and inspecting display screens to ensure functionality

3. Quality Control

Fabricators are responsible for maintaining high-quality standards throughout the fabrication process. This includes inspecting components and assemblies, identifying defects, and implementing corrective measures.

- Inspecting display screens for defects and imperfections

- Identifying and resolving quality issues during the fabrication process

4. Process Optimization

Continuous improvement is essential in manufacturing. Fabricators are involved in analyzing production processes, identifying areas for improvement, and implementing changes to enhance efficiency and reduce costs.

- Identifying and implementing process improvements

- Optimizing production processes to increase efficiency and reduce waste

Interview Tips

Preparing for an interview for a Display Screen Fabricator position requires a combination of technical knowledge and soft skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the company and the display screen fabrication industry. This will help you understand the company’s products, market position, and recent developments.

- Visit the company’s website and social media pages

- Read industry articles and news to stay informed about the latest trends

2. Highlight Relevant Experience and Skills

Make sure your resume and interview answers emphasize your relevant experience and skills. This could include experience in fabricating electronic components, assembling display screens, or working in a quality control environment.

- Quantify your accomplishments using specific metrics

- Provide examples of how you have applied your skills to solve problems and improve processes

3. Practice Your Technical Knowledge

Be prepared to answer questions about the technical aspects of display screen fabrication. This may include questions about materials, assembly techniques, and quality control procedures.

- Review basic principles of display screen technology

- Familiarize yourself with industry-standard fabrication techniques

4. Emphasize Your Attention to Detail and Quality

Display Screen Fabricators must have a keen eye for detail and a commitment to quality. Highlight your ability to identify and resolve defects, and your understanding of quality control processes.

- Describe your experience using measuring and inspection equipment

- Explain how you maintain a clean and organized work area

5. Show Your Enthusiasm and Motivation

Hiring managers are looking for candidates who are passionate about display screen fabrication. Show your enthusiasm for the industry and express your motivation to learn and grow in the field.

- Share your knowledge of the latest display screen technologies

- Explain why you are interested in working for the specific company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Display Screen Fabricator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!