Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ditcher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

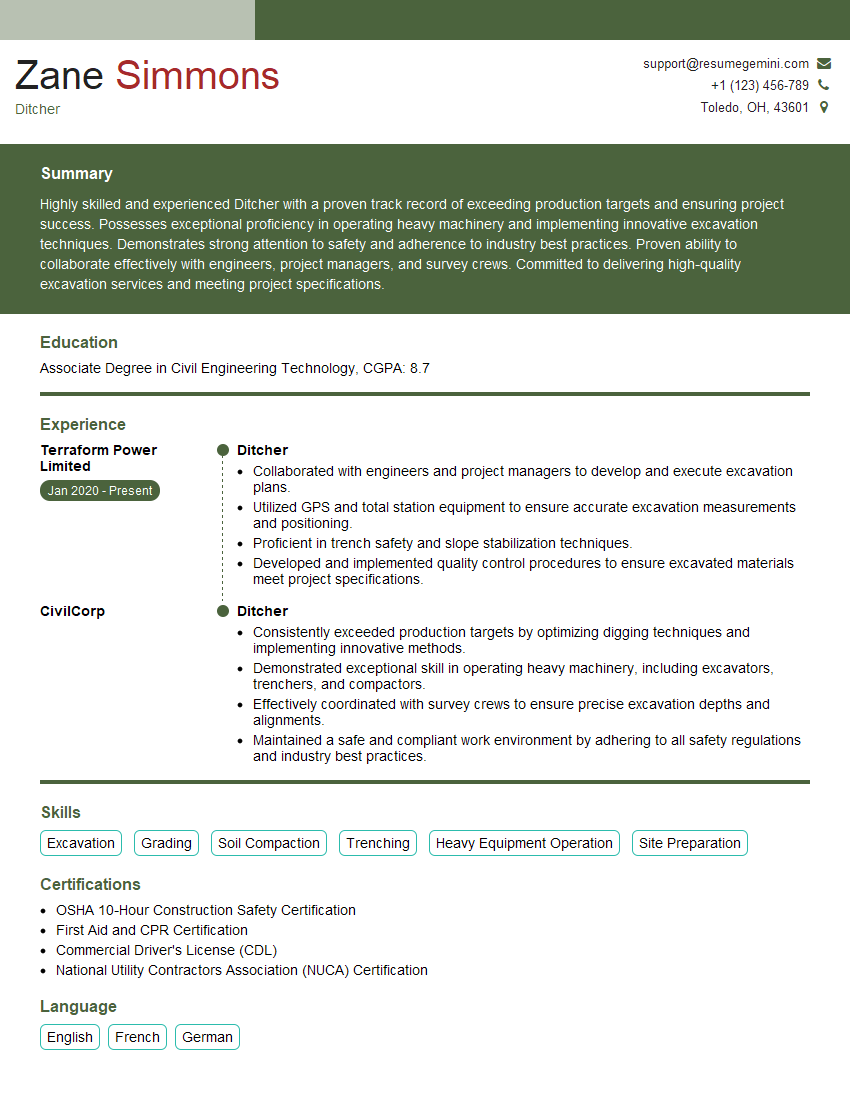

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ditcher

1. What are the key responsibilities of a Ditcher?

- Operating and maintaining ditching machines to create trenches for pipelines, cables, and other underground utilities.

- Inspecting and preparing work areas, including clearing vegetation and removing obstacles.

- Monitoring the ditching process to ensure accuracy, efficiency, and safety.

- Performing preventative maintenance and repairs on ditching machines.

- Adhering to safety protocols and regulations related to excavation work.

2. What types of ditching machines are you familiar with?

Types of Ditching Machines

- Chain trenchers

- Wheel trenchers

- Plow trenchers

- Backhoes

- Micro trenchers

Experience with Different Machines

- Chain trenchers: Experience in operating and maintaining chain trenchers for large-scale trenching projects.

- Wheel trenchers: Familiarity with the use of wheel trenchers for medium-sized trenching applications.

- Plow trenchers: Knowledge and experience in utilizing plow trenchers for shallow trenching in various soil conditions.

3. How do you ensure the accuracy and precision of the trenching process?

- Utilizing surveying equipment to establish accurate trench depth and alignment.

- Employing grade control systems to maintain consistent trench profiles.

- Performing regular calibration and maintenance of ditching machines.

- Adhering to specified trenching plans and specifications.

- Monitoring the trenching process and making necessary adjustments to ensure accuracy.

4. What are the different soil conditions you have experience working with when ditching?

- Sandy soils: Experience in trenching through sandy soils, which require careful handling to prevent cave-ins.

- Clay soils: Familiarity with the challenges of trenching in clay soils, which can become sticky and difficult to excavate.

- Rocky soils: Knowledge and experience in trenching through rocky soils, requiring specialized equipment and techniques.

- Wet soils: Expertise in operating ditching machines in wet conditions, where soil stability and water drainage must be managed.

5. How do you handle obstacles encountered during ditching, such as underground utilities or rocks?

- Utilizing utility locators to identify and avoid underground utilities.

- Employing hand tools or specialized equipment to remove rocks and other obstacles.

- Adjusting the trenching path or depth to bypass obstacles without compromising project specifications.

- Communicating with project engineers or supervisors to determine the best course of action.

6. What safety precautions do you take when operating ditching machines?

- Wearing appropriate personal protective equipment (PPE), including hard hat, safety glasses, and gloves.

- Inspecting the ditching machine and work area prior to operation.

- Establishing safe working distances and barriers around the trenching area.

- Monitoring weather conditions and adjusting operations accordingly.

- Following all established safety protocols and procedures.

7. How do you maintain and troubleshoot ditching machines?

- Performing regular inspections and maintenance tasks.

- Identifying and troubleshooting minor issues before they become major problems.

- Replacing worn or damaged parts.

- Calibrating and adjusting the machine for optimal performance.

- Collaborating with mechanics or other technical experts for complex repairs.

8. What are the different trenching techniques you are familiar with?

- Conventional trenching: Standard method using a chain or wheel trencher for deep and wide trenches.

- Micro trenching: Specialized technique for creating narrow trenches for fiber optic cables.

- Plow trenching: Method that utilizes a plow to create shallow trenches for utility lines.

- Rock trenching: Specialized techniques for excavating trenches in rocky soil conditions.

9. How do you ensure that the trenches meet the required depth, width, and slope specifications?

- Utilizing surveying equipment to establish accurate trench dimensions.

- Employing grade control systems to maintain consistent trench profiles.

- Regularly checking trench dimensions throughout the ditching process.

- Adjusting the ditching machine settings and techniques as needed.

10. Can you describe a challenging trenching project you have worked on and how you overcame the difficulties?

- Describe the project and the specific challenges encountered, such as difficult soil conditions, tight timelines, or obstacles.

- Explain the strategies and techniques used to overcome the challenges.

- Highlight the successful outcomes and lessons learned from the project.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ditcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ditcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ditcher is primarily responsible for operating and maintaining ditching equipment used in the excavation and maintenance of irrigation and drainage canals, ditches, and other water conveyance systems. They work under the supervision of a supervisor or foreman and are expected to perform a range of duties related to ditching operations.

1. Equipment Operation

The primary responsibility of a Ditcher is to operate heavy equipment such as excavators, backhoes, and trenchers to dig, clean, and maintain ditches and canals. They must be proficient in using these machines and have a good understanding of their capabilities and limitations.

- Operate excavators, backhoes, and trenchers to dig, clean, and maintain ditches and canals

- Control the depth, width, and slope of ditches to meet specifications

- Adjust machine settings and attachments to optimize performance

2. Maintenance and Inspection

Apart from operating the equipment, Ditchers are also responsible for maintaining and inspecting ditching equipment to ensure its proper functioning. They perform regular maintenance tasks such as lubrication, cleaning, and minor repairs to keep the machines in good working condition.

- Perform routine maintenance and inspections on ditching equipment

- Identify and troubleshoot equipment problems

- Make minor repairs and adjustments as needed

3. Site Preparation and Safety

Before starting ditching operations, Ditchers prepare the worksite by clearing obstacles, marking boundaries, and setting up safety measures. They also ensure that the work area is free from hazards and that all necessary safety protocols are followed during the operation.

- Prepare the worksite by clearing obstacles, marking boundaries, and setting up safety measures

- Identify and assess potential hazards

- Follow all safety regulations and procedures

4. Quality Control

Ditchers are responsible for ensuring the quality of their work. They monitor the progress of ditching operations and make necessary adjustments to meet specifications and maintain the desired depth, width, and slope of the ditches. They also inspect the completed ditches to ensure they meet the required standards.

- Monitor the progress of ditching operations and make necessary adjustments

- Inspect completed ditches to ensure they meet specifications

- Maintain accurate records of ditching activities

Interview Tips

Preparing well for a Ditcher interview can significantly increase your chances of success. Here are some tips to help you ace the interview and make a positive impression on the hiring manager.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s culture, values, and the specific responsibilities of the role.

- Visit the company’s website and social media pages

- Read industry news and articles

- Talk to people who work or have worked for the company

2. Practice Your Answers

Once you have a good understanding of the company and the position, start practicing your answers to common interview questions. This will help you feel more confident and prepared during the actual interview.

- Prepare for questions about your experience, skills, and qualifications

- Think about questions you might ask the interviewer

- Practice answering questions out loud

3. Dress Professionally

First impressions matter, so dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the industry and the company culture.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Choose shoes that are comfortable and professional

4. Be On Time

Punctuality is important for any interview, but it is especially important for a Ditcher interview. Ditchers are expected to be punctual and reliable, so arriving on time for your interview will show the hiring manager that you are serious about the position.

- Plan your route in advance and give yourself plenty of time to get to the interview

- If you are running late, call the interviewer to let them know

- Arrive at the interview location a few minutes early

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ditcher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!