Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ditching Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

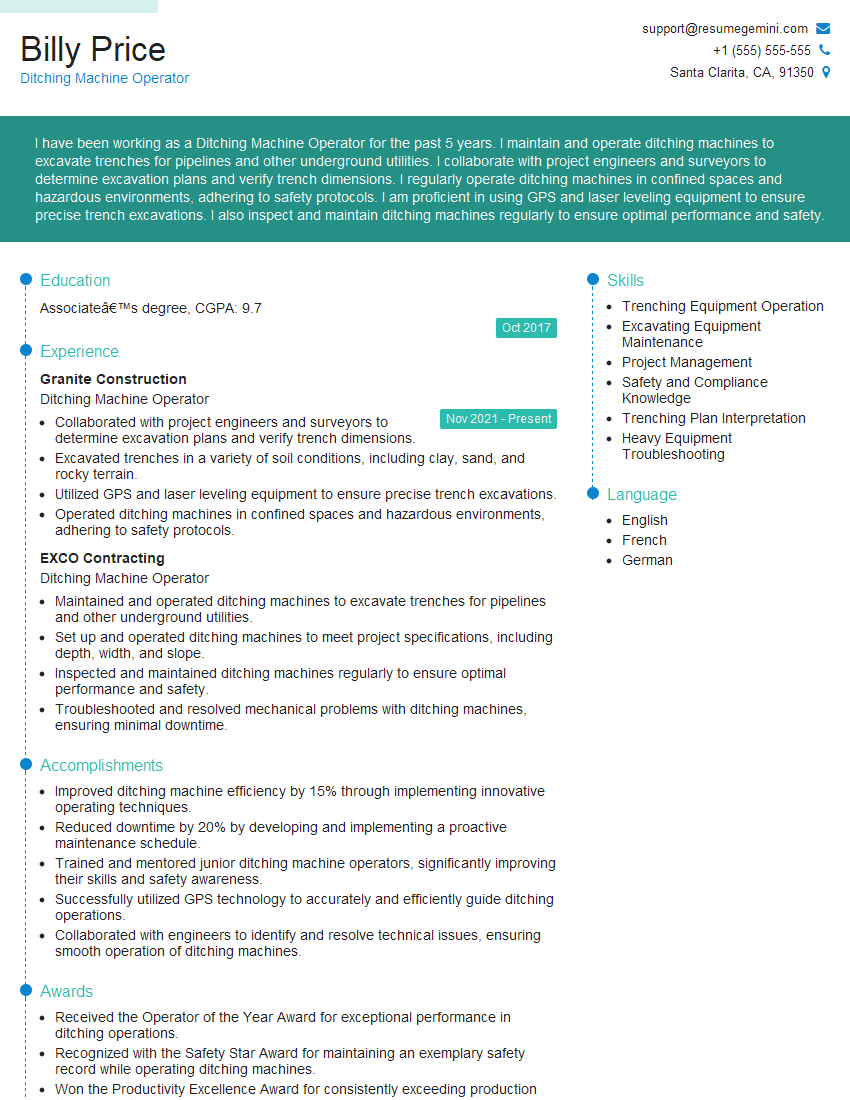

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ditching Machine Operator

1. What are the types of ditching machines?

There are various types of ditching machines used in different applications. Some of the most common types include:

- Trenchers: Used for digging narrow, deep trenches for pipelines, cables, or drainage systems.

- Backhoes: Versatile machines with a hydraulic arm and bucket, used for digging ditches, holes, and other excavation tasks.

- Chain trenchers: Feature a continuous chain with cutting teeth, used for digging trenches with steep sidewalls.

- Wheel trenchers: Have a series of cutting wheels mounted on a rotating frame, used for digging trenches in hard or rocky soil.

2. What are the key factors to consider when selecting a ditching machine?

Job Requirements

- Depth and width of the trench

- Soil conditions

- Presence of obstacles

- Required production rate

Machine Capabilities

- Size and power of the machine

- Digging depth and width

- Attachment options

- Safety features

3. What are the daily maintenance tasks required for a ditching machine?

Daily maintenance tasks for a ditching machine include:

- Checking and topping up fluid levels (oil, hydraulic fluid, fuel)

- Inspecting filters and cleaning or replacing as needed

- Greasing moving parts

- Checking for loose bolts or connections

- Cleaning the machine of dirt and debris

4. How do you ensure the safety of yourself and others when operating a ditching machine?

Safety precautions when operating a ditching machine include:

- Wearing appropriate PPE (hard hat, safety glasses, gloves)

- Inspecting the machine before use and reporting any defects

- Following established safety protocols

- Being aware of surroundings and potential hazards

- Using proper lifting techniques

5. What are the common problems that can occur with ditching machines and how do you troubleshoot them?

Problem:

Machine not digging deep enoughTroubleshooting:

- Check if the digging chain is worn or damaged

- Inspect the hydraulic pressure and flow

- Adjust the digging angle or depth settings

Problem:

Excessive vibrationTroubleshooting:

- Check the balance of the cutting wheel or chain

- Inspect for loose bolts or connections

- Adjust the machine’s speed or digging depth

6. What are the advantages of using a laser guidance system on a ditching machine?

Advantages of laser guidance systems on ditching machines include:

- Improved accuracy and precision in digging depth and alignment

- Reduced rework and material waste

- Increased productivity and efficiency

- Reduced operator fatigue and strain

7. How do you calculate the productivity of a ditching machine?

Productivity of a ditching machine can be calculated using the following formula:

Productivity = (Length of trench dug / Time taken)

Units can be meters per hour or feet per hour, depending on the measurement system used.

8. What is the purpose of a spoil conveyor on a ditching machine?

A spoil conveyor on a ditching machine serves the following purposes:

- Transporting excavated soil away from the trench

- Creating a spoil pile or spreading the soil evenly along the side of the trench

- Preventing soil from falling back into the trench

9. How do you handle different soil conditions when operating a ditching machine?

Adjusting the machine’s settings and attachments is necessary to handle different soil conditions:

Hard or rocky soil:

- Use a rock cutter attachment

- Reduce the digging speed

- Apply additional downward force

Soft or wet soil:

- Use a wider digging chain or wheel

- Increase the digging speed

- Use a spoil conveyor to prevent soil from sticking

10. What is the role of a Ditching Machine Operator in a construction project?

The role of a Ditching Machine Operator in a construction project includes:

- Operating the ditching machine to dig trenches for pipelines, cables, or drainage systems

- Ensuring the accuracy and depth of the trenches

- Maintaining and servicing the ditching machine

- Working as part of a team to complete the project

- Following safety protocols and regulations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ditching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ditching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ditching machine operators are responsible for operating and maintaining ditching machines, used to create trenches for laying pipes, cables, and other underground infrastructure. They must have a strong understanding of machine operation and maintenance procedures, as well as a comprehensive knowledge of safety protocols.

1. Machine Operation

The primary responsibility of a ditching machine operator is to operate the machine efficiently and safely. This involves:

- Preparing the machine for operation, including checking fluid levels, inspecting components, and starting the engine.

- Controlling the machine’s speed, depth, and alignment while digging the trench.

- Monitoring the machine’s performance and making adjustments as needed to ensure optimal operation.

- Shutting down the machine properly at the end of the shift.

2. Maintenance and Troubleshooting

To ensure the ditching machine is operating at peak performance, operators must also perform routine maintenance and troubleshooting tasks. This includes:

- Performing daily inspections and cleaning the machine.

- Lubricating moving parts.

- Checking and replacing filters.

- Diagnosing and repairing minor problems.

- Coordinating with mechanics for major repairs.

3. Safety Compliance

Ditching machine operators must adhere to strict safety protocols to protect themselves and others from potential hazards. This involves:

- Wearing appropriate personal protective equipment (PPE).

- Following established safety procedures, including lockout/tagout.

- Inspecting the work area for potential hazards.

- Maintaining a clean and organized work environment.

- Responding appropriately to emergencies.

4. Communication and Teamwork

Ditching machine operators often work as part of a team, so effective communication and teamwork are crucial. This involves:

- Communicating with supervisors, other operators, and site personnel.

- Coordinating work activities to minimize downtime.

- Providing input on machine operation and maintenance to improve efficiency.

- Working safely and cooperatively with other team members.

Interview Tips

1. Preparation

Preparation is key to acing any interview. Research the company, the position, and the industry to gain a thorough understanding of the opportunity. Practice answering common interview questions and prepare specific examples that demonstrate your skills and experience.

- Research the company’s website, social media pages, and industry news to learn about their culture, values, and recent developments.

- Carefully review the job description and identify the key skills and qualifications required for the position.

- Practice answering common interview questions, such as: “Tell me about yourself,” “Why are you interested in this position?,” and “What are your strengths and weaknesses?”.

- Prepare specific examples from your previous experience that demonstrate your abilities in machine operation, maintenance, safety compliance, and teamwork.

2. Professionalism

First impressions matter, so make sure to dress professionally and arrive on time for your interview. Be polite and respectful to everyone you meet, from the receptionist to the interviewer.

- Dress in business casual attire or a suit, depending on the company’s culture.

- Arrive at the interview location 10-15 minutes early to allow for unexpected delays.

- Greet the interviewer with a firm handshake and make eye contact.

- Be polite and respectful to everyone you interact with, regardless of their position.

3. Enthusiasm and Confidence

Employers are looking for candidates who are enthusiastic about the position and confident in their abilities. Show them that you are passionate about ditching machine operation and that you have the skills and experience necessary to succeed in the role.

- Be enthusiastic about the position and the company.

- Speak confidently about your skills and experience.

- Make eye contact with the interviewer and speak clearly.

- Ask thoughtful questions about the position and the company.

4. Follow-up

After the interview, be sure to follow up with the interviewer to thank them for their time and reiterate your interest in the position. This is a good opportunity to address any questions or concerns that may have come up during the interview.

- Send a thank-you email within 24 hours of the interview.

- Reiterate your interest in the position and thank the interviewer for their time.

- Address any questions or concerns that were not discussed during the interview.

- Inquire about the next steps in the hiring process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ditching Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!