Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Double End Tenon Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

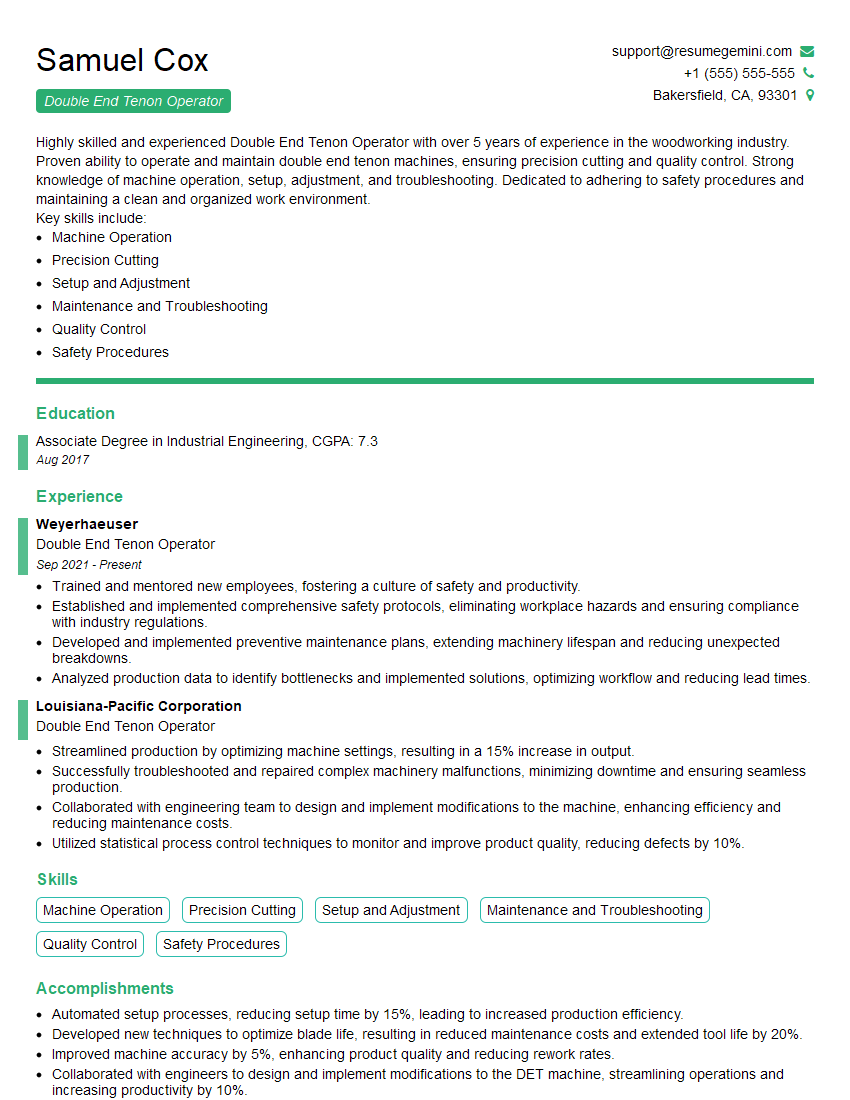

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Double End Tenon Operator

1. What are key technical skills required to be a successful Double End Tenon Operator?

- Knowledge of double end tenon machines and their operation

- Proficiency in set up and operation of double end tenon machines

- Ability to read and interpret blueprints and work orders

- Knowledge of wood properties and characteristics

- Strong attention to detail and accuracy

- Ability to work independently and as part of a team

2. What are the different types of double end tenon machines?

subheading of the answer

- Horizontal Double End Tenon Machines

- Vertical Double End Tenon Machines

subheading of the answer

- Single Head Double End Tenon Machines

- Double Head Double End Tenon Machines

3. What are safety precautions that should be taken when operating a double end tenon machine?

- Always wear appropriate safety gear, including safety glasses, earplugs, and gloves

- Never operate the machine if you are not properly trained

- Keep your hands away from the cutting area

- Be aware of the location of the emergency stop button

4. What are quality control checks that should be performed on double end tenon joints?

- Check the tenon for the correct size and shape

- Check the mortise for the correct size and shape

- Ensure that the tenon is properly seated in the mortise

- Check the joint for any gaps or misalignment

5. What are the common problems that can occur when operating a double end tenon machine, and how would you troubleshoot them?

- Problem: The tenon is not the correct size or shape

Troubleshooting: Check the cutter settings and make sure they are correct for the desired tenon size and shape - Problem: The mortise is not the correct size or shape

Troubleshooting: Check the cutter settings and make sure they are correct for the desired mortise size and shape - Problem: The tenon is not properly seated in the mortise

Troubleshooting: Check the alignment of the machine and make sure that the tenon and mortise are properly aligned - Problem: The joint has gaps or misalignment

Troubleshooting: Check the alignment of the machine and make sure that the tenon and mortise are properly aligned

6. What is maintenance schedule for a double end tenon machine?

- Daily: Check the machine for any loose parts or damage

- Weekly: Clean the machine and lubricate all moving parts

- Monthly: Inspect the cutters and replace them if necessary

- Quarterly: Perform a complete maintenance check of the machine, including checking the electrical system and hydraulics

7. What are the different types of wood that can be processed on a double end tenon machine?

- Softwoods, such as pine, fir, and spruce

- Hardwoods, such as oak, maple, and cherry

- Engineered wood products, such as plywood and MDF

8. What are the different types of tenon joints that can be produced on a double end tenon machine?

- Single tenon joints

- Double tenon joints

- Mortise and tenon joints

- Dovetail joints

9. How can you increase the efficiency of a double end tenon machine?

- Use sharp cutters

- Keep the machine clean and well-maintained

- Set up the machine correctly for the desired joint

- Use the correct feed rate for the material being processed

10. How can you reduce the waste produced by a double end tenon machine?

- Use the correct cutter size for the desired joint

- Set up the machine correctly to minimize waste

- Use the correct feed rate for the material being processed

- Recycle the waste material

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Double End Tenon Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Double End Tenon Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Double End Tenon Operator is responsible for overseeing and operating a double end tenon machine, which is used to create tenons (protrusions) on both ends of wooden workpieces. The operator’s primary duties include:

1. Machine Operation and Maintenance

Operate the double end tenon machine according to established procedures, ensuring the efficient and accurate production of tenons on wooden workpieces.

- Monitor machine performance, identifying and resolving any potential issues or malfunctions.

- Perform regular maintenance and cleaning of the machine, ensuring optimal functionality and longevity.

2. Material Handling

Load and unload wooden workpieces into and out of the double end tenon machine, ensuring proper positioning and alignment.

- Inspect workpieces for defects or inconsistencies, ensuring that only high-quality pieces are processed.

- Maintain a clean and organized work area, minimizing the risk of accidents or damage to materials.

3. Quality Control

Inspect tenoned workpieces for accuracy and quality, ensuring they meet specifications and customer requirements.

- Identify and correct any defects or inconsistencies in tenons, ensuring the production of high-quality finished products.

- Maintain accurate records of production output and quality control measures, providing data for performance monitoring and improvement.

4. Safety and Compliance

Adhere to all safety regulations and procedures, ensuring a safe and compliant work environment.

- Wear appropriate personal protective equipment (PPE) and follow proper safety protocols.

- Comply with all environmental regulations and standards, ensuring the responsible and sustainable operation of the machine.

Interview Tips

To prepare for an interview for a Double End Tenon Operator position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and products or services. Research the specific role and its responsibilities to gain a clear understanding of the expectations.

- Visit the company’s website and review its mission statement, company profile, and relevant news articles.

- Look for industry-specific publications or online forums to gather insights into the company’s reputation and market position.

2. Practice Your Answers to Common Interview Questions

Anticipate common interview questions and prepare thoughtful and concise answers. Practice your responses to highlight your skills, experience, and qualifications.

- Tell me about your experience operating a double end tenon machine.

- Describe your approach to quality control and ensuring the accuracy of tenons.

- How do you handle unexpected challenges or malfunctions with the machine?

3. Highlight Your Safety and Compliance Knowledge

Emphasize your understanding of safety protocols and environmental regulations related to operating woodworking machinery.

- Provide examples of your commitment to maintaining a safe work environment.

- Explain your knowledge of relevant industry standards and regulations.

4. Show Your Attention to Detail and Problem-Solving Abilities

Demonstrate your meticulousness and ability to identify and resolve issues in a timely and efficient manner.

- Describe situations where you identified and corrected errors or inconsistencies in tenon production.

- Explain how you troubleshoot and resolve common problems with the double end tenon machine.

5. Prepare Questions for the Interviewer

Preparing insightful questions to ask the interviewer shows your interest in the position and the company.

- Inquire about the company’s growth plans and the role of the Double End Tenon Operator within those plans.

- Ask about opportunities for professional development and advancement within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Double End Tenon Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!