Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Double Head Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

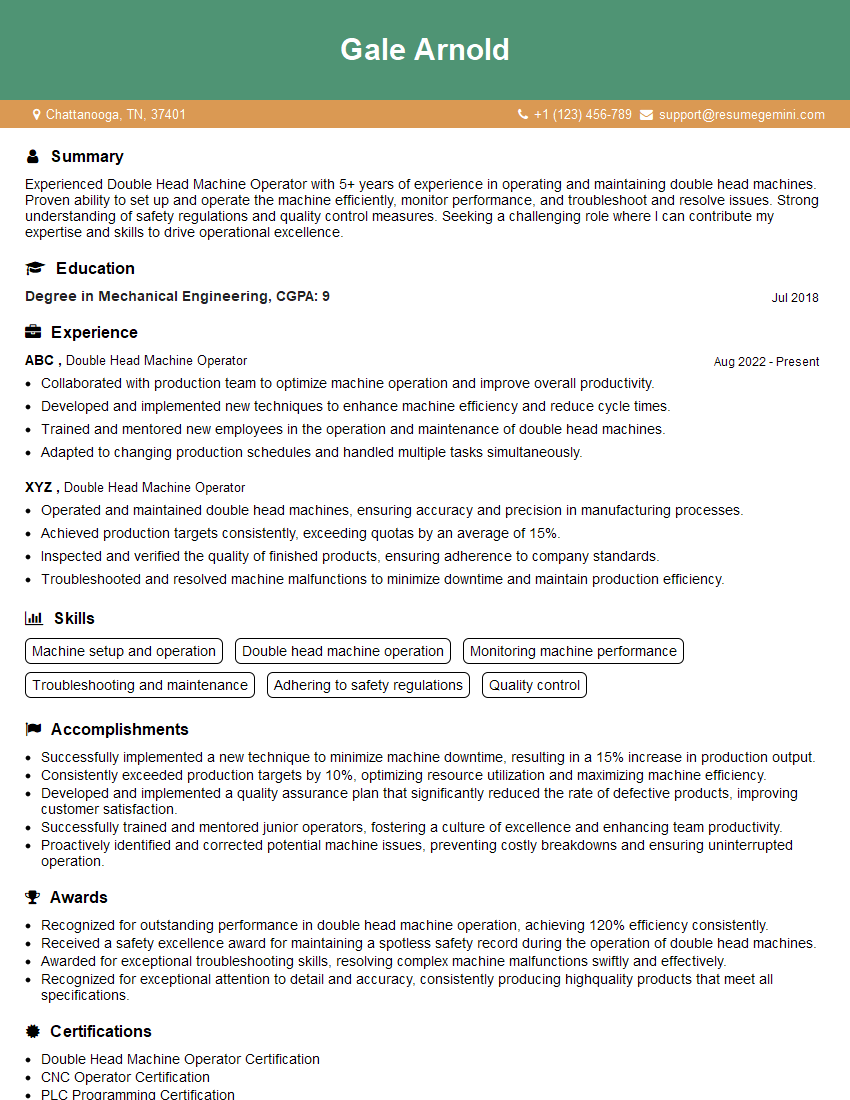

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Double Head Machine Operator

1. Describe the steps involved in setting up a double head machine for a new job.

Sample Answer

- Review the job specifications and drawings to understand the required dimensions and tolerances.

- Select and install the appropriate cutting tools and fixtures.

- Calibrate the machine’s axes and spindles to ensure accuracy.

- Load the material and set the workpiece in position.

- Program the machine with the required operations and feed rates.

2. How do you ensure the quality of parts produced on a double head machine?

Sample Answer

Inspection and Measurement

- Use measuring tools such as calipers, micrometers, and indicators to inspect parts for dimensional accuracy.

- Visually examine parts for any defects or imperfections.

Preventive Maintenance

- Regularly clean and lubricate the machine to minimize wear and tear.

- Monitor the machine’s performance and identify any potential issues.

3. What are the common types of materials used in double head machining?

Sample Answer

- Metals (e.g., steel, aluminum, stainless steel)

- Plastics (e.g., ABS, PVC, polycarbonate)

- Woods (e.g., hardwood, softwood, plywood)

- Composite materials (e.g., fiberglass, carbon fiber)

4. How do you handle troubleshooting issues on a double head machine?

Sample Answer

- Identify the source of the problem by analyzing machine logs, error messages, and physical inspection.

- Consult technical documentation or consult with experienced machinists for solutions.

- Make necessary adjustments or repairs to resolve the issue.

- Document the solution and update the machine’s maintenance records.

5. What are the safety precautions to consider when operating a double head machine?

Sample Answer

- Wear appropriate safety gear (e.g., gloves, safety glasses, earplugs)

- Ensure guards and safety mechanisms are in place and operating properly.

- Inspect the machine before each use and remove any debris or obstacles.

- Be aware of the potential for flying chips and swarf.

6. How do you optimize the efficiency of a double head machine?

Sample Answer

- Use sharp and properly maintained cutting tools.

- Choose the appropriate cutting speeds and feed rates for the material and operation.

- Minimize setup and changeover times.

- Monitor the machine’s performance and make adjustments to optimize cycle times.

7. What are the different types of double head machines?

Sample Answer

- Horizontal double head machines

- Vertical double head machines

- Gantry double head machines

- CNC double head machines

8. What is the difference between a double head machine and a single head machine?

Sample Answer

- Double head machines have two cutting heads, while single head machines have only one.

- Double head machines can perform multiple operations simultaneously, making them more efficient for certain types of machining.

9. What are the benefits of using a double head machine?

Sample Answer

- Increased productivity

- Reduced cycle times

- Improved accuracy and repeatability

- Greater flexibility and versatility

10. How do you maintain a double head machine?

Sample Answer

- Clean and lubricate the machine regularly.

- Inspect and replace worn or damaged parts.

- Calibrate the machine to ensure accuracy.

- Follow manufacturer’s recommendations for maintenance and troubleshooting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Double Head Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Double Head Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Double Head Machine Operators are responsible for operating and maintaining double head machines used in the production of various products. Key responsibilities include:1. Machine Operation

- Setting up and operating double head machines according to specifications

- Loading and unloading materials into the machine

- Monitoring machine performance and making adjustments as needed

- Maintaining a clean and safe work area

2. Machine Maintenance

- Performing routine maintenance tasks on the machine

- Troubleshooting and resolving minor machine issues

- Reporting major machine issues to supervisors or maintenance personnel

- Keeping accurate records of machine maintenance and repairs

3. Quality Control

- Inspecting products produced by the machine for quality

- Identifying and correcting product defects

- Adhering to company quality standards and procedures

- Providing feedback to supervisors or quality control personnel on product quality issues

4. Safety

- Following all safety rules and regulations

- Wearing appropriate personal protective equipment (PPE)

- Reporting any unsafe conditions or practices

- Maintaining a safe and healthy work environment

Interview Tips

To ace your interview for a Double Head Machine Operator position, follow these tips:1. Research the Company and Position

- Visit the company website and learn about their products, services, and culture

- Read online reviews and articles about the company

- Review the job description carefully and identify key skills and responsibilities

2. Highlight Your Skills and Experience

- Quantify your experience and provide specific examples of your accomplishments

- Use keywords from the job description in your resume and cover letter

- Be prepared to discuss your experience in operating and maintaining double head machines

3. Demonstrate Your Quality Control Abilities

- Describe your experience in inspecting products for quality

- Explain your understanding of quality standards and procedures

- Give examples of how you have identified and corrected product defects

4. Emphasize Your Safety Consciousness

- State your commitment to safety and following all safety rules and regulations

- Describe your experience in wearing PPE and maintaining a safe work environment

- Explain how you would report any unsafe conditions or practices

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Double Head Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.