Feeling lost in a sea of interview questions? Landed that dream interview for Double Needle Stitcher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Double Needle Stitcher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

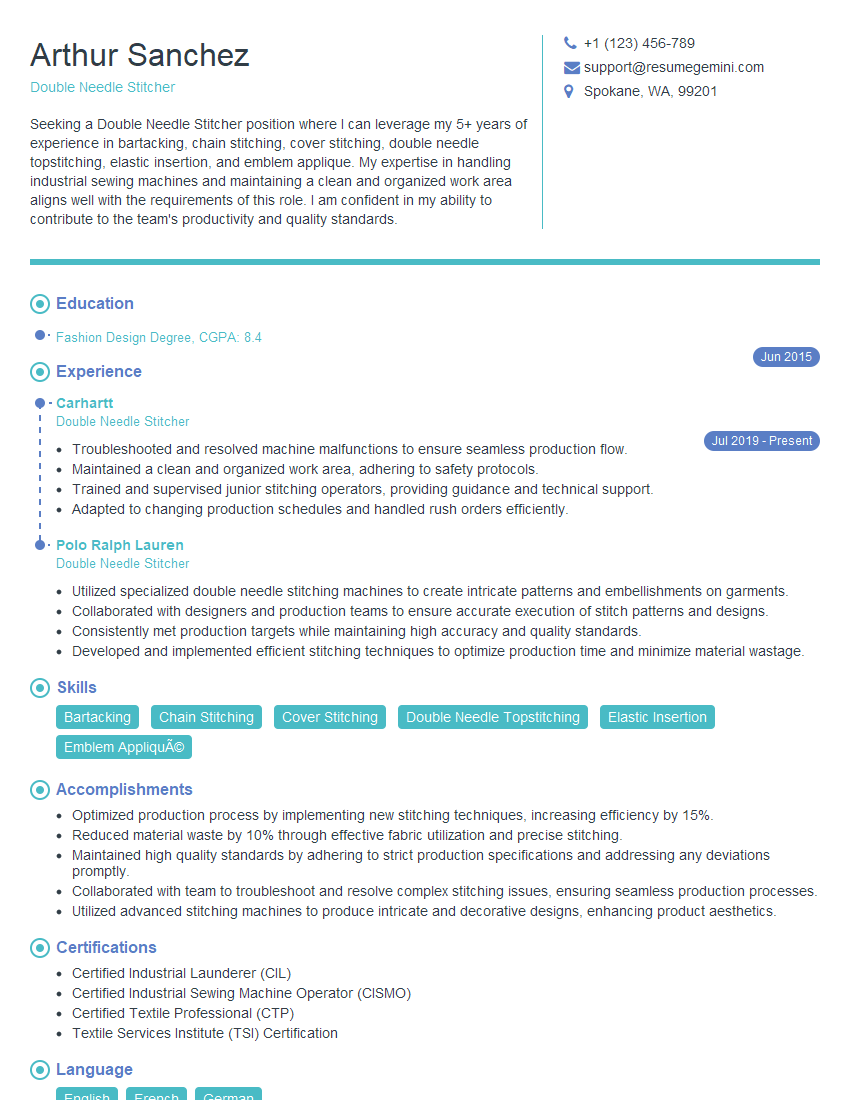

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Double Needle Stitcher

1. What are the different types of double needle stitching machines?

There are various types of double needle stitching machines, including:

- Plain double needle stitching machines

- Cylinder bed double needle stitching machines

- Flat bed double needle stitching machines

- Overlock double needle stitching machines

2. How do you maintain a double needle stitching machine?

Daily Maintenance

- Clean the machine head and needles regularly.

- Oil the machine according to the manufacturer’s instructions.

- Check the needle tension and adjust as needed.

Weekly Maintenance

- Remove the needle plate and bobbin case for thorough cleaning.

- Inspect the feed dog and adjust or replace as necessary.

- Check the belt tension and adjust if loose.

3. What are the common problems with double needle stitching machines and how do you troubleshoot them?

Some common problems with double needle stitching machines include:

- Skipped stitches: This can be caused by incorrect needle tension, improper threading, or worn needles.

- Broken needles: This can be caused by using the wrong needle size or type for the fabric, or by hitting a hard object.

- Uneven stitching: This can be caused by incorrect needle spacing, worn machine parts, or improper tension settings.

4. What are the safety precautions that you must take when operating a double needle stitching machine?

- Always wear safety glasses when operating the machine.

- Do not reach into the machine while it is running.

- Keep your hands away from the needles at all times.

- Unplug the machine before performing any maintenance or repairs.

5. What is the difference between a single needle stitching machine and a double needle stitching machine?

A single needle stitching machine uses one needle to create a single line of stitching, while a double needle stitching machine uses two needles to create two parallel lines of stitching. Double needle stitching is often used for decorative purposes or to create a stronger seam.

6. What types of fabrics are best suited for double needle stitching?

- Medium to heavyweight fabrics, such as denim, canvas, and leather

- Woven fabrics with a tight weave, such as cotton and polyester

- Knits that are not too stretchy

7. What are the different types of double needle stitches?

- Plain stitch: Two parallel lines of stitching

- Topstitch stitch: Two parallel lines of stitching with a decorative top stitch

- Coverstitch stitch: Two parallel lines of stitching with a third line of stitching that covers the raw edge of the fabric

- Overlock stitch: Two parallel lines of stitching with a third line of stitching that overcasts the raw edge of the fabric

8. How do you select the correct needle size and thread for double needle stitching?

The correct needle size and thread for double needle stitching will depend on the fabric you are using and the desired stitch type. In general, a larger needle size will be needed for heavier fabrics, and a smaller needle size will be needed for lighter fabrics. The thread should be strong enough to withstand the double needle stitching, and it should be a color that matches or complements the fabric.

9. How do you adjust the needle tension on a double needle stitching machine?

The needle tension on a double needle stitching machine can be adjusted by turning the tension dials on the top of the machine. The tension should be tight enough to prevent the thread from breaking, but not so tight that the fabric puckers or the needles bend.

10. What is the proper way to thread a double needle stitching machine?

To thread a double needle stitching machine, follow these steps:

- Raise the presser foot.

- Open the needle clamp and insert the left needle.

- Close the needle clamp.

- Thread the left needle from the spool to the tension dial.

- Pull the thread through the needle.

- Repeat steps 2-5 for the right needle.

- Place the bobbin in the bobbin case.

- Thread the bobbin thread through the bobbin tension dial.

- Pull the bobbin thread up through the needle plate.

- Lay the bobbin thread over the left needle and under the right needle.

- Pull both threads to the back of the machine.

- Lower the presser foot and begin sewing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Double Needle Stitcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Double Needle Stitcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Double Needle Stitcher is responsible for operating industrial-grade sewing machines to stitch together pieces of fabric or other materials. They play a crucial role in the manufacturing process of garments, upholstery, and other textile products.

1. Machine Operation

Double Needle Stitchers are highly skilled in operating double-needle sewing machines. They are responsible for:

- Setting up and maintaining sewing machines, including threading needles, adjusting stitch length and tension, and ensuring proper machine lubrication.

- Loading and unloading fabric or other materials onto the machine and guiding them through the sewing process.

- Monitoring the stitching process and making adjustments as needed to ensure precision and quality.

- Troubleshooting and resolving any machine issues that arise during operation.

2. Material Handling

Double Needle Stitchers are also responsible for handling and managing the materials being stitched. This includes:

- Inspecting materials for defects or damage before stitching.

- Folding and positioning materials correctly on the sewing machine.

- Ensuring that the materials are fed into the machine smoothly and evenly.

- Removing stitched pieces from the machine and inspecting them for quality.

3. Quality Control

Double Needle Stitchers play a vital role in maintaining quality standards in the manufacturing process:

- Monitoring the stitch quality and making adjustments to ensure that the stitches meet specifications.

- Inspecting finished products for defects, such as skipped stitches, broken threads, or uneven seams.

- Identifying and reporting any quality issues to supervisors or quality control personnel.

4. Safety Compliance

Double Needle Stitchers are responsible for adhering to safety regulations and guidelines. This includes:

- Wearing appropriate safety gear, such as protective eyewear and gloves.

- Following established safety procedures when operating sewing machines.

- Maintaining a clean and organized work area to prevent accidents.

- Reporting any safety hazards or concerns to supervisors.

Interview Tips

An interview for a Double Needle Stitcher position can be competitive. Here are some tips to help you ace the interview and make a lasting impression on the hiring manager:

1. Research the Company and the Role

Before the interview, take the time to thoroughly research the company you are applying to and the specific Double Needle Stitcher role. This shows the interviewer that you are genuinely interested in the position and that you have taken the time to understand their needs.

2. Highlight Your Skillset

In the interview, be sure to highlight your skills and experience that are directly relevant to the Double Needle Stitcher role. Emphasize your proficiency in operating double-needle sewing machines, your attention to detail, and your commitment to quality. Provide specific examples of your work that demonstrate your abilities.

3. Showcase Your Teamwork Skills

Double Needle Stitchers often work in close collaboration with other team members. In the interview, highlight your ability to work well in a team environment and your willingness to contribute to the team’s success.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows the interviewer that you are engaged and interested in the position. Prepare a few questions that demonstrate your interest in the company and the role, such as questions about the company’s commitment to quality, their employee development opportunities, or their growth plans.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Double Needle Stitcher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Double Needle Stitcher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.