Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Doubler Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Doubler Helper so you can tailor your answers to impress potential employers.

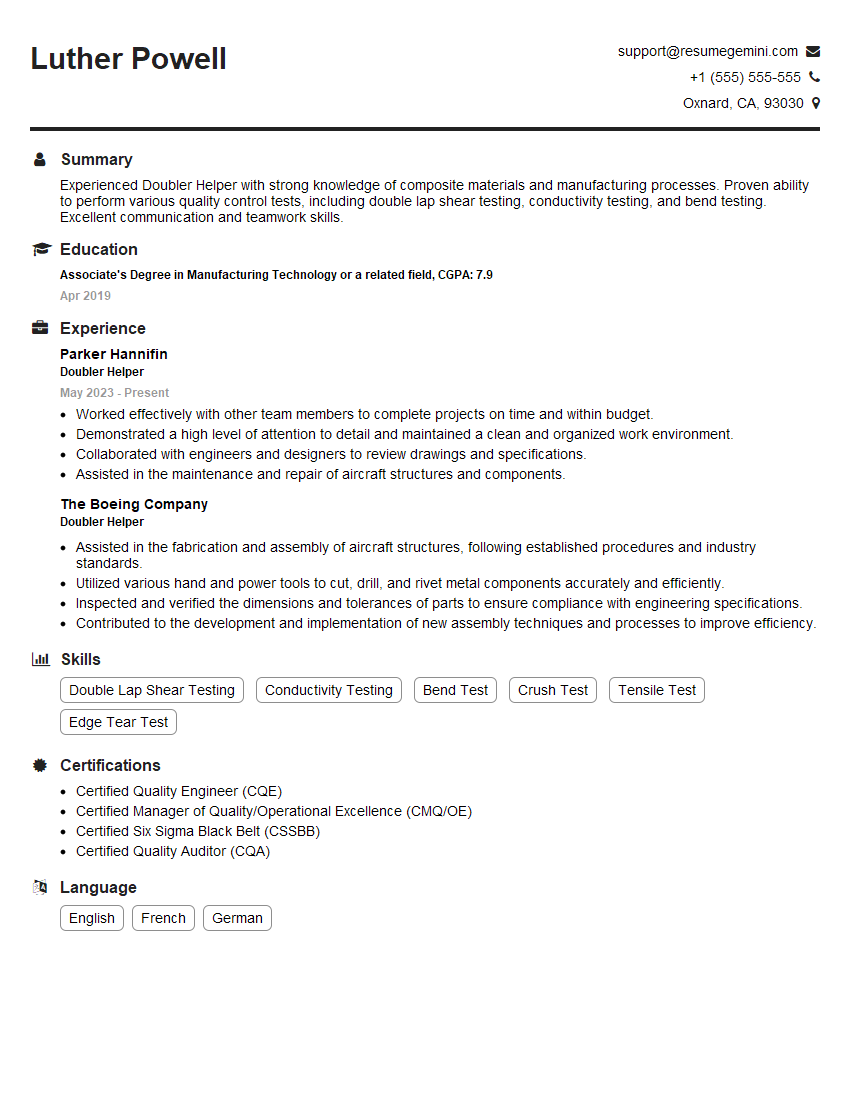

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Doubler Helper

1. What are the responsibilities of a Doubler Helper?

As a Doubler Helper, my key responsibilities would include:

- Assisting in the preparation and installation of doublers on aircraft structures

- Performing quality control checks on doublers and adjacent areas to ensure compliance with specifications

- Maintaining a clean and organized work area, ensuring safety protocols are followed

- Operating and maintaining equipment used in the doubler process, such as drills, riveters, and inspection tools

- Collaborating with team members to efficiently complete projects within established timelines

2. Can you explain the process of installing a doubler on an aircraft structure?

The process of installing a doubler on an aircraft structure typically involves the following steps:

Surface Preparation

- Cleaning and preparing the surface where the doubler will be installed

- Ensuring the surface is free from any contaminants, corrosion, or other defects

Doubler Preparation

- Inspecting the doubler for any damage or defects

- Applying adhesive or sealant to the doubler as per specifications

Doubler Installation

- Positioning the doubler on the prepared surface and securing it with fasteners

- Applying additional adhesive or sealant around the edges of the doubler

Inspection and Finishing

- Thoroughly inspecting the installed doubler to ensure proper adhesion and alignment

- Applying touch-up paint or sealant as necessary to complete the installation

3. What types of materials are commonly used for doublers?

The selection of materials for doublers depends on the specific application and requirements. Some commonly used materials include:

- Aluminum alloys: Strong, lightweight, and corrosion-resistant, suitable for a wide range of aircraft structures

- Composite materials: High strength-to-weight ratio, resistant to fatigue and corrosion, used in critical load-bearing areas

- Steel alloys: High strength and durability, often used in areas subjected to high loads or impact

- Titanium alloys: Excellent strength-to-weight ratio, corrosion-resistant, used in high-performance aircraft

4. What are the different types of fasteners used in doubler installation?

The type of fasteners used in doubler installation depends on the material of the doubler and the structure it is being attached to. Some common types include:

- Rivets: Permanent fasteners that create a strong mechanical bond between the doubler and the structure

- Bolts: Threaded fasteners that allow for disassembly and reassembly

- Screws: Similar to bolts, but typically smaller in size and used for lighter loads

- Adhesives: Bonding agents that create a strong and durable joint between the doubler and the structure

5. What are the common challenges faced during doubler installation?

Some common challenges faced during doubler installation include:

- Proper surface preparation: Ensuring the surface is clean and free from contaminants is crucial for a strong bond

- Accurate alignment: The doubler must be precisely aligned and positioned to avoid any misalignment or gaps

- Material compatibility: Choosing the right materials and fasteners for the specific application is essential to ensure compatibility and durability

- Adhesive application: Proper application of adhesives is critical to achieve the desired bond strength and prevent premature failure

- Quality control: Thorough inspections are necessary to ensure the doubler is installed correctly and meets all specifications

6. How do you ensure quality control during doubler installation?

To ensure quality control during doubler installation, I follow a systematic approach that includes:

- Visual inspections: Thoroughly examining the doubler and the installation area for any defects or damage

- Dimensional checks: Using precision measuring tools to verify that the doubler is installed according to specifications

- Adhesion testing: Conducting non-destructive tests to assess the bond strength between the doubler and the structure

- Documentation: Maintaining detailed records of all inspections and test results for traceability and future reference

7. What safety precautions should be taken when working with doublers and aircraft structures?

When working with doublers and aircraft structures, it is crucial to adhere to the following safety precautions:

- Wear appropriate PPE: Safety glasses, gloves, and protective clothing to minimize the risk of injuries

- Use proper tools and equipment: Ensure all tools are in good condition and used correctly to prevent accidents

- Follow established procedures: Comply with all safety guidelines and protocols to avoid any hazards

- Maintain a clean and organized work area: Keep the work area free from tripping hazards and clutter to prevent accidents

- Be aware of your surroundings: Pay attention to the movement of equipment and personnel to avoid collisions

8. How do you handle situations when you encounter unexpected problems during doubler installation?

When faced with unexpected problems during doubler installation, I approach the situation systematically:

- Assess the problem: Identify the root cause of the issue and evaluate its potential impact

- Consult with team members: Seek input from experienced colleagues or supervisors to gather different perspectives

- Explore alternative solutions: Brainstorm and evaluate multiple options to address the problem effectively

- Implement a solution: Choose the most appropriate solution and execute it with precision

- Document the process: Record the problem, the solution implemented, and the outcome for future reference

9. Can you describe a project where you successfully installed doublers on an aircraft structure?

In my previous role at XYZ Aerospace, I was involved in a project to install doublers on the wing structure of a commercial airliner. The project involved:

- Preparing the wing surface and the doublers according to specifications

- Installing the doublers using high-strength adhesives and fasteners

- Conducting rigorous quality control checks throughout the installation process

- Successfully completing the project within the specified timeframe and meeting all quality standards

10. How do you stay updated with the latest techniques and best practices in doubler installation?

To keep abreast of the latest techniques and best practices in doubler installation, I engage in the following activities:

- Attend industry conferences and workshops: Network with experts and learn about innovative approaches

- Read technical publications and journals: Stay informed about advancements in materials, adhesives, and installation methods

- Participate in online forums and discussion groups: Engage with professionals and exchange knowledge

- Seek guidance from experienced mentors: Learn from individuals who have extensive expertise in doubler installation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Doubler Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Doubler Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Doubler Helpers support the Doubler in the timely and efficient installation and repair of rigid and flexible ductwork on commercial and industrial projects. They must be able to work effectively both independently and as part of a team. Key job responsibilities include:

1. Material Handling

Load and unload materials from delivery trucks, including sheet metal, ductwork, and other related supplies.

- Operate forklifts and other material handling equipment to move materials safely and efficiently.

- Maintain a clean and organized work area, ensuring materials are stored securely and accessible.

2. Installation Support

Assist the Doubler in installing and securing ductwork, using appropriate tools and techniques.

- Cut and shape ductwork according to specifications.

- Hang and support ductwork using hangers, brackets, and other hardware.

3. Tool and Equipment Maintenance

Maintain and inspect tools and equipment, ensuring they are in good working condition.

- Sharpen and replace blades.

- Lubricate and adjust equipment as needed.

4. Safety and Compliance

Follow all safety protocols and procedures, including wearing appropriate PPE and maintaining a safe work environment.

- Report any hazards or unsafe conditions to the Doubler.

- Comply with all applicable codes and regulations.

Interview Tips

Preparing thoroughly for your Doubler Helper interview can significantly increase your chances of success. Here are a few tips to help you ace the interview:

1. Research the Company and Position

Take the time to learn about the company’s history, values, and current projects. This will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the latest trends.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers beforehand. This will help you organize your thoughts and deliver your responses confidently.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Recall specific examples from your work experience that highlight your relevant skills and qualifications.

3. Highlight Your Skills and Abilities

Emphasize the skills and abilities that are most relevant to the Doubler Helper role. These may include:

- Material handling experience

- Ductwork installation knowledge

- Tool and equipment maintenance skills

- Ability to work independently and as part of a team

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your curiosity and knowledge of the industry.

- Ask about the current projects the company is working on.

- Inquire about the company’s growth plans and future goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Doubler Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!