Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Doubler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

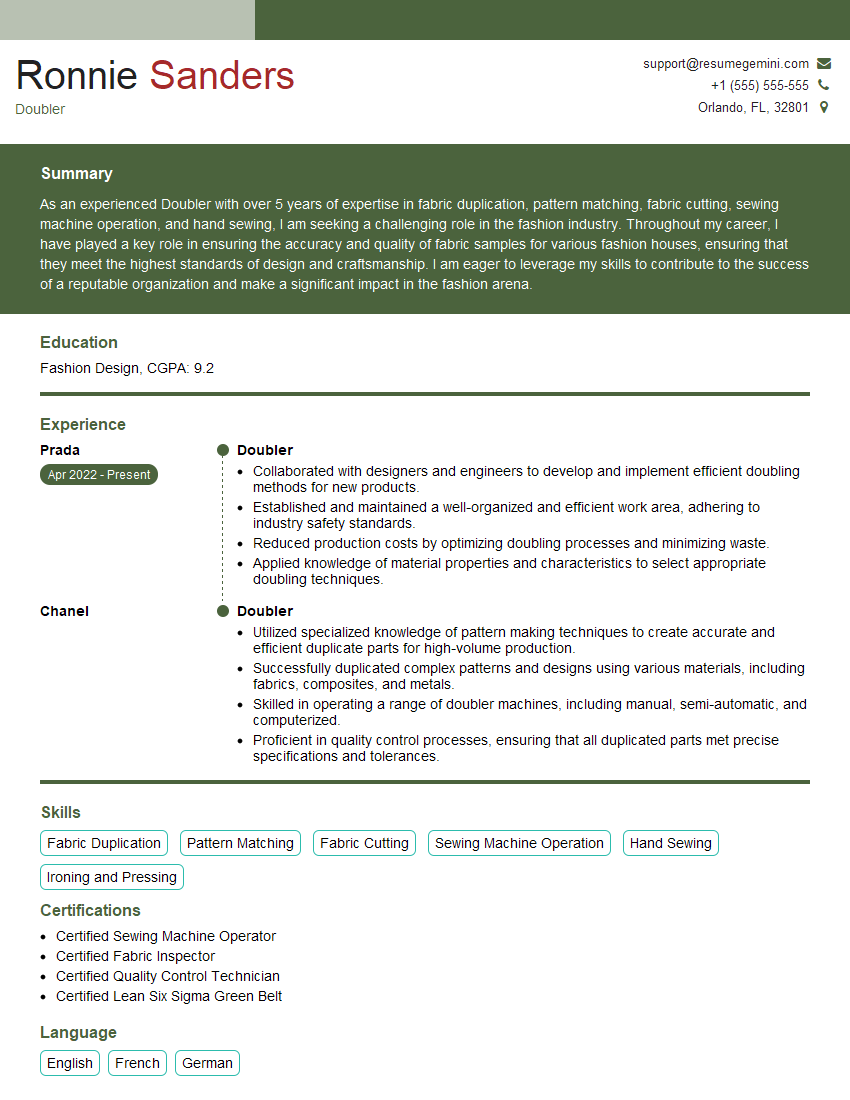

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Doubler

1. Explain the primary responsibility of a Doubler.

As a Doubler, my primary responsibility would be to assist in the production of composite aircraft structures by accurately duplicating existing parts or creating new ones using composite materials.

2. What are the key skills and experience a Doubler candidate should possess?

Technical Skills

- Expertise in composite material fabrication and repair

- Proficiency in using doubler tooling and equipment

- Understanding of composite material properties and bonding techniques

- Ability to interpret engineering drawings and specifications

- Familiarity with quality assurance and inspection procedures

Experience

- Previous experience in an aerospace or composite manufacturing environment

- Experience in duplicating or fabricating composite parts

- Strong attention to detail and a commitment to quality

- Excellent communication and teamwork skills

- Ability to work independently and follow instructions precisely

3. Can you describe the steps involved in doubling a composite part?

The steps involved in doubling a composite part typically include:

- Inspecting the existing part to assess its condition and identify areas for doubling

- Preparing the doubler material by cutting and shaping it to the required dimensions

- Applying adhesive or bonding agents to the doubler and existing part

- Positioning the doubler precisely over the designated area and securing it using clamps or tooling

- Curing the adhesive or bond under controlled conditions to achieve optimal strength

- Inspecting the doubled part to ensure proper adhesion and structural integrity

4. What are the different types of composite materials typically used in doubling operations and their advantages?

- Carbon fiber reinforced polymers (CFRPs): High strength-to-weight ratio, excellent stiffness, and durability

- Glass fiber reinforced polymers (GFRPs): Lower cost than CFRPs, good strength and stiffness, suitable for non-critical applications

- Aramid fiber reinforced polymers (AFRPs): High impact resistance, good heat resistance, often used in aircraft structures

- Hybrid composites: Combine different fiber types to achieve specific properties, such as improved strength, stiffness, or impact resistance

5. Explain the importance of quality assurance in doubling operations and how it is maintained.

Quality assurance in doubling operations is crucial to ensure the structural integrity and performance of the repaired or reinforced part. It involves:

- Inspecting raw materials and finished products to meet specifications

- Adhering to established bonding and curing procedures

- Conducting non-destructive testing (NDT) to verify bond quality

- Maintaining proper documentation and traceability throughout the process

6. Describe the use of specialized tooling and equipment in doubling operations.

Specialized tooling and equipment are essential for accurate and efficient doubling:

- Doubler presses: Used to apply pressure and maintain alignment during bonding

- Vacuum bagging equipment: Creates a vacuum to remove air and improve bonding

- Temperature-controlled ovens: Used for curing adhesives under controlled conditions

- NDT equipment: Used to inspect bond quality, such as ultrasonic testing or infrared thermography

7. How do you handle deviations or non-conformities during doubling operations?

Deviations or non-conformities during doubling operations should be addressed promptly to maintain quality:

- Identify the deviation and analyze its potential impact

- Consult with engineering or quality control personnel for guidance

- Implement corrective actions to resolve the non-conformity

- Document the deviation and corrective actions taken

8. What safety precautions should be considered when working with composite materials and adhesives?

- Wear appropriate personal protective equipment (PPE), such as gloves, respirators, and eye protection

- Ensure proper ventilation to avoid exposure to harmful fumes

- Handle and store composite materials and adhesives safely to prevent damage or contamination

- Follow established safety protocols and guidelines

9. How do you stay updated with advancements in composite materials and doubling techniques?

To stay updated with advancements in composite materials and doubling techniques:

- Attend industry conferences and seminars

- Read technical journals and publications

- Participate in professional development courses

- Network with other professionals in the field

10. How do you prioritize tasks and manage your time effectively when working on multiple projects?

- Create a task list and prioritize tasks based on urgency and importance

- Use time management tools and techniques, such as the Pomodoro Technique

- Delegate tasks to team members when appropriate

- Communicate regularly with supervisors and colleagues to ensure timely completion

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Doubler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Doubler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Doubler plays a crucial role in the manufacturing industry, working with various materials to create durable, customized parts.

1. Material Handling and Preparation

Handling raw materials, including leather, textiles, and plastics.

- Measuring and cutting materials precisely using tools like rulers, scissors, and knives.

- Preparing materials by applying adhesives or other bonding agents.

2. Part Production

Creating parts according to specifications, using tools and machinery.

- Joining materials together using sewing machines, adhesives, or other techniques.

- Assembling parts to form complete products.

3. Quality Control

Inspecting parts and products to ensure they meet quality standards.

- Checking for defects, such as misalignment, uneven stitching, or incorrect dimensions.

- Reworking or rejecting parts that do not meet specifications.

4. Maintenance and Repair

Maintaining and repairing equipment used in the doubling process.

- Cleaning and lubricating machinery.

- Identifying and fixing minor equipment issues.

Interview Tips

Preparing for an interview for a Doubler position requires a combination of technical knowledge and soft skills.

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and specific requirements for the Doubler role.

- Visit the company’s website.

- Read industry news and articles.

2. Highlight Relevant Skills and Experience

Emphasize your expertise in material handling, part production, and quality control.

- Quantify your accomplishments using specific examples.

- Explain how your skills align with the job requirements.

3. Practice Common Interview Questions

Anticipate and prepare answers to typical interview questions.

- Tell me about your experience in the doubling process.

- Describe your quality control procedures.

4. Be Professional and Enthusiastic

Dress appropriately and maintain a positive attitude throughout the interview.

- Arrive on time.

- Make eye contact and actively engage with the interviewer.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Doubler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Doubler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.