Are you gearing up for a career in Dough Brake Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dough Brake Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

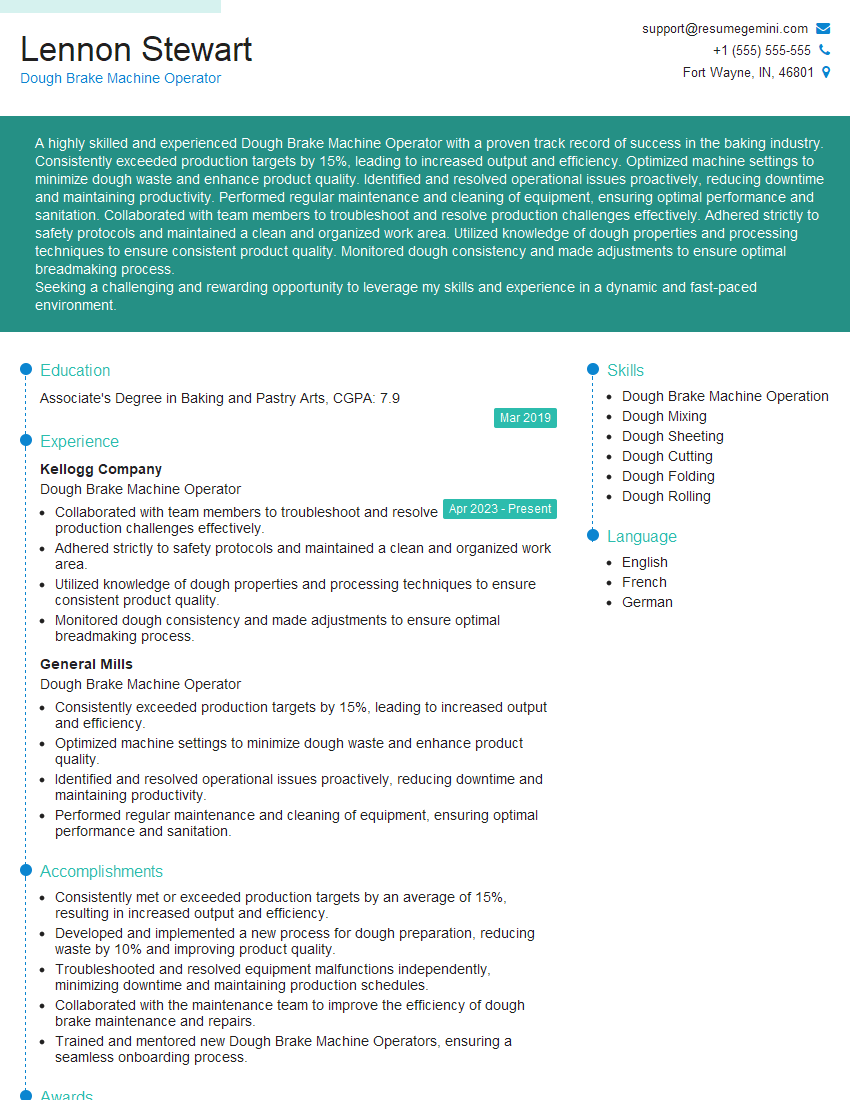

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dough Brake Machine Operator

1. Explain the process of setting up a dough brake machine?

- Inspect and clean the machine.

- Mount the dough sheet on the infeed conveyor.

- Adjust the conveyor speed and brake pressure to desired settings.

- Set the dough thickness using the thickness adjustment mechanism.

- Calibrate the machine to ensure accurate and consistent braking.

2. Describe the different types of doughs that can be processed on a dough brake machine?

Laminated doughs:

- Croissants

- Puff pastry

Yeast-raised doughs:

- Bread dough

- Pizza dough

Cookie doughs:

- Chocolate chip cookie dough

- Sugar cookie dough

3. How do you troubleshoot a dough brake machine that is not braking properly?

- Check if the brake pressure is set correctly.

- Inspect the brake pads for wear and tear.

- Examine the conveyor speed and adjust it if necessary.

- Check for any blockages or obstructions in the machine.

- Calibrate the machine to ensure accurate and consistent braking.

4. What are the safety precautions that must be taken when operating a dough brake machine?

- Wear appropriate safety gear, including gloves, safety glasses, and hair nets.

- Keep hands and clothing away from moving parts.

- Never reach into the machine while it is running.

- Lock out and tag out the machine before performing any maintenance or repairs.

- Follow all manufacturer’s instructions and safety protocols.

5. How do you maintain a dough brake machine to ensure optimal performance?

- Clean the machine regularly to remove dough residue and debris.

- Lubricate moving parts according to the manufacturer’s instructions.

- Inspect and replace brake pads as needed.

- Calibrate the machine to ensure accurate and consistent braking.

- Perform regular maintenance checks to identify and address any potential problems.

6. How do you optimize the production process on a dough brake machine?

- Set up the machine efficiently to minimize downtime.

- Monitor the machine’s performance and adjust settings as needed.

- Train operators on proper operation and maintenance techniques.

- Implement a quality control system to ensure consistent product quality.

- Follow manufacturer’s recommendations for production speeds and dough handling.

7. Describe the different types of dough brake machines available?

- Manual dough brake machines: Operated by hand.

- Semi-automatic dough brake machines: Assisted by electric or hydraulic power.

- Fully-automatic dough brake machines: Controlled by a computer or PLC.

- Vertical dough brake machines: Dough is fed vertically through the machine.

- Horizontal dough brake machines: Dough is fed horizontally through the machine.

8. What are the factors to consider when selecting a dough brake machine for a particular application?

- Type of dough to be processed.

- Desired dough thickness.

- Production capacity requirements.

- Available space and layout.

- Budget and cost considerations.

9. How do you ensure that the dough is braked evenly and consistently?

- Calibrate the machine to ensure accurate and consistent braking.

- Use a dough brake machine with multiple braking zones.

- Monitor the machine’s performance and adjust settings as needed.

- Train operators on proper operation techniques.

- Implement a quality control system to ensure consistent product quality.

10. Describe the importance of dough braking in the production of laminated doughs?

- Creates even layers of dough and butter.

- Prevents dough from shrinking or tearing.

- Improves the texture and flavor of the final product.

- Allows for the development of a flaky and crispy crust.

- Enhances the overall quality and appearance of laminated doughs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dough Brake Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dough Brake Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dough Brake Machine Operators are responsible for operating and maintaining dough brake machines, which are used to divide and shape dough into uniform pieces. They must have a thorough understanding of the machine’s operation and be able to troubleshoot any problems that may arise.

1. Operating the Dough Brake Machine

Operators are responsible for setting up and operating the dough brake machine according to the manufacturer’s instructions.

- Loading the dough into the machine

- Adjusting the machine’s settings to produce the desired dough piece size and shape

- Monitoring the machine’s operation to ensure that it is running smoothly

2. Maintaining the Dough Brake Machine

Operators are also responsible for maintaining the dough brake machine to ensure that it is in good working order.

- Cleaning the machine regularly

- Lubricating the machine’s moving parts

- Inspecting the machine for any damage or wear and tear

3. Troubleshooting Dough Brake Machine Problems

Operators must be able to troubleshoot any problems that may arise with the dough brake machine.

- Identifying the cause of the problem

- Taking corrective action to fix the problem

- Reporting any problems to the supervisor

4. Other Responsibilities

In addition to the above responsibilities, Dough Brake Machine Operators may also be responsible for:

- Packaging and storing the dough pieces

- Assisting with other tasks in the bakery

- Maintaining a clean and safe work area

Interview Tips

To ace an interview for a Dough Brake Machine Operator position, candidates should be prepared to discuss their experience operating and maintaining dough brake machines. They should also be able to demonstrate their knowledge of the different types of dough brake machines and the different types of dough that can be processed with them.

1. Research the Company and the Position

Before the interview, candidates should research the company and the specific position they are applying for. This will help them to understand the company’s culture and the expectations for the position.

- Visit the company’s website

- Read the job description carefully

- Look up the company on LinkedIn and Glassdoor

2. Practice Your Answers

Candidates should practice answering common interview questions. This will help them to feel more confident and prepared during the interview.

- What is your experience operating and maintaining dough brake machines?

- What are the different types of dough brake machines?

- What are the different types of dough that can be processed with a dough brake machine?

- How do you troubleshoot problems with a dough brake machine?

3. Dress Professionally

Candidates should dress professionally for the interview. This will show the interviewer that they are serious about the position and that they respect the company.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Avoid wearing strong perfumes or colognes

4. Be on Time

Candidates should arrive for the interview on time. This shows the interviewer that they are respectful of the company’s time and that they are organized.

- Plan your route in advance

- Allow extra time for traffic or unexpected delays

- If you are running late, call the interviewer to let them know

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dough Brake Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!