Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dovetail Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

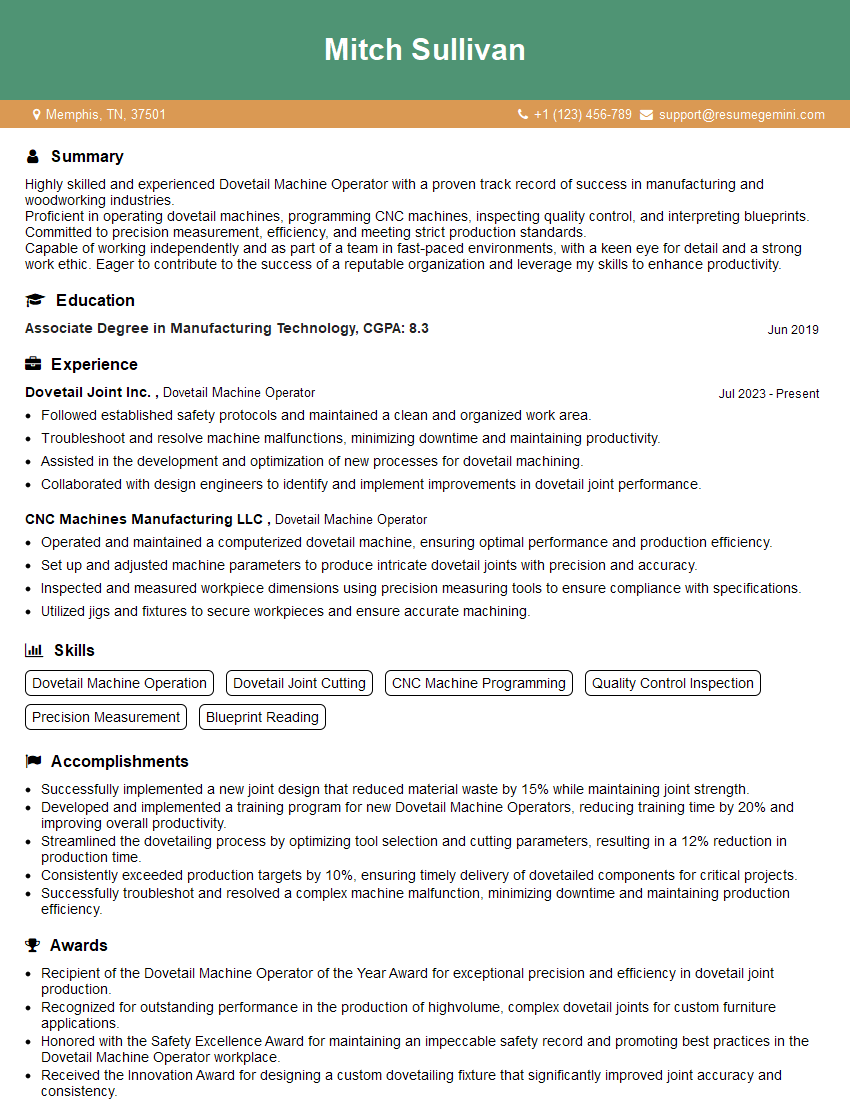

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dovetail Machine Operator

1. Describe the process of setting up a dovetail machine.

- Inspect the machine to ensure that it is in good working order.

- Mount the workpiece and secure it with clamps.

- Select the appropriate cutting tool and install it in the machine.

- Adjust the machine settings, such as speed and feed rate, according to the material being cut.

- Run a test cut to ensure that the machine is functioning properly and that the workpiece is being cut correctly.

2. What are the different types of dovetail joints, and how are they used?

Through dovetail joint

- Provide high-strength across the joint

- Used in drawer construction

Half-blind dovetail joint

- Visible on one side

- Used for decorative and functional purposes, such as in furniture and cabinetry

Sliding dovetail joint

- Allows for easy disassembly and assembly

- Used in applications where frequent access to the joint is required, such as in drawers and boxes

3. What are the common problems that can occur when operating a dovetail machine, and how can they be resolved?

Problem: The machine is not cutting cleanly.

- The cutting tool may be dull or damaged.

- The machine settings may not be correct.

- The workpiece may not be securely clamped.

Problem: The machine is making excessive noise.

- The machine may be in need of lubrication.

- The cutting tool may be dull or damaged.

- The machine settings may be incorrect.

Problem: The machine is vibrating excessively.

- The workpiece may not be securely clamped.

- The machine may be in need of maintenance.

- The machine may be operating at too high of a speed or feed rate.

4. How do you maintain a dovetail machine?

- Clean the machine regularly to remove dust and debris.

- Lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine regularly for any signs of wear or damage.

- Have the machine serviced by a qualified technician on a regular basis.

5. What safety precautions should be followed when operating a dovetail machine?

- Wear appropriate safety gear, such as safety glasses, gloves, and a dust mask.

- Keep hands and loose clothing away from the cutting tool.

- Do not operate the machine if you are tired or under the influence of drugs or alcohol.

- Be aware of the location of the emergency stop button and how to use it.

6. What is the difference between a dovetail machine and a router?

- Dovetail machines are specifically designed for cutting dovetail joints.

- Routers can be used to cut a variety of joints, including dovetail joints.

- Dovetail machines are typically more expensive than routers.

- Dovetail machines are more precise than routers.

7. What are the advantages of using a dovetail machine?

- Dovetail joints are very strong and durable.

- Dovetail joints are aesthetically pleasing.

- Dovetail machines are easy to operate.

8. What are the disadvantages of using a dovetail machine?

- Dovetail machines can be expensive.

- Dovetail machines require a lot of setup time.

- Dovetail machines can be dangerous if not used properly.

9. What experience do you have operating a dovetail machine?

I have been operating dovetail machines for the past 5 years. I am proficient in setting up and operating the machine, and I have a deep understanding of how to produce high-quality dovetail joints.

10. Why are you interested in this position?

I am interested in this position because I am passionate about woodworking. I am always looking for ways to improve my skills, and I believe that working as a dovetail machine operator would be a great opportunity to do so. I am also eager to contribute my skills and experience to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dovetail Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dovetail Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dovetail Machine Operator is a professional responsible for operating and maintaining dovetail machines used in the woodworking industry to create precision joints between pieces of wood. The operator sets up, operates, and maintains the machine, ensuring the production of high-quality dovetail joints crucial for furniture construction, cabinetry, and other woodworking projects.

1. Machine Operation

The operator is responsible for the seamless operation of the dovetail machine. This involves setting up the machine according to the workpiece specifications, including selecting the appropriate cutters and jigs.

- Set up and adjust the machine according to workpiece specifications

- Select and install appropriate cutters and jigs

- Monitor machine performance and make adjustments as required

2. Quality Control

The operator is responsible for ensuring the quality of the dovetail joints produced by the machine. This involves inspecting the joints for accuracy, precision, and strength.

- Inspect dovetail joints for accuracy and precision

- Check joint strength and ensure it meets specifications

- Identify and correct any defects or inconsistencies

3. Maintenance and Troubleshooting

The operator is responsible for maintaining the dovetail machine in good working condition. This involves performing regular maintenance tasks and troubleshooting any issues that may arise.

- Perform regular maintenance tasks, such as cleaning, lubrication, and calibration

- Troubleshoot and resolve machine malfunctions

- Follow maintenance schedules and ensure machine is in optimal condition

4. Safety Compliance

The operator is responsible for adhering to all safety regulations and procedures when operating the dovetail machine. This includes wearing appropriate safety gear and following established safety protocols.

- Follow safety regulations and wear appropriate safety gear

- Operate machine in a safe and responsible manner

- Report any safety concerns or hazards to supervisor

Interview Tips

Preparing thoroughly for a Dovetail Machine Operator interview is crucial to showcasing your skills and knowledge.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. Familiarize yourself with the company’s history, values, and products, as well as the responsibilities and requirements of the Dovetail Machine Operator role.

- Visit the company website and social media pages

- Read industry news and articles

- Identify the specific skills and experience required for the position

2. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers. Anticipate questions about your experience, skills, and knowledge related to dovetail machine operation. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples of your abilities.

- Describe your experience operating dovetail machines

- Explain how you ensure the accuracy and quality of dovetail joints

- Provide examples of troubleshooting and resolving machine malfunctions

3. Highlight Your Safety Knowledge and Compliance

Emphasize your commitment to safety and compliance in your interview. Explain your understanding of safety regulations and procedures, and provide examples of how you prioritize safety in your work.

- Discuss your knowledge of safety regulations for dovetail machine operation

- Describe your experience following safety protocols and wearing appropriate safety gear

- Explain how you maintain a safe and hazard-free work environment

4. Showcase Your Passion for Woodworking

If you have a genuine passion for woodworking, let it shine through in your interview. Explain how your interest and enthusiasm for woodworking led you to pursue a career as a Dovetail Machine Operator.

- Explain your interest in woodworking and how it motivated you to become a Dovetail Machine Operator

- Share your knowledge of different types of wood and woodworking techniques

- Discuss your appreciation for the precision and craftsmanship involved in dovetail joinery

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dovetail Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.