Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Doweler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Doweler so you can tailor your answers to impress potential employers.

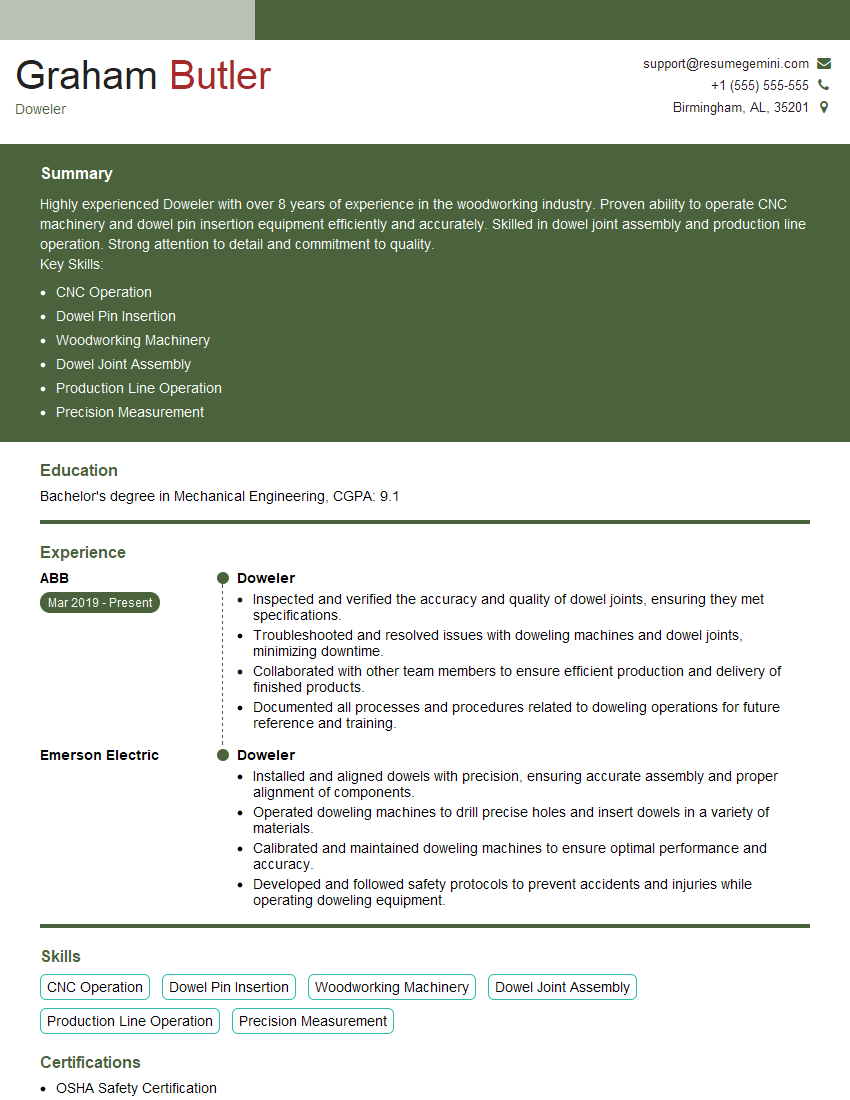

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Doweler

1. Can you explain the process of doweling and its importance in woodworking?

Doweling is a woodworking technique that involves inserting wooden dowels into holes drilled into two pieces of wood to join them together. It is a strong and durable method of joining, especially for pieces that will be subjected to stress or movement.

- Doweling provides a strong and durable joint that can withstand stress and movement.

- It is a relatively simple and straightforward process that can be done with basic tools.

- Doweling can be used to join a variety of different types of wood, including hardwood, softwood, and plywood.

2. What are the different types of dowel joints and when would you use each type?

Edge-to-edge joint

- Used to join two pieces of wood that are aligned edge-to-edge.

- Strong and durable joint that is suitable for a variety of applications.

Face-to-face joint

- Used to join two pieces of wood that are aligned face-to-face.

- Strong and durable joint that is ideal for applications where the joint will not be visible.

Mitre joint

- Used to join two pieces of wood that are cut at a 45-degree angle.

- Strong and durable joint that is ideal for applications where the joint will be visible.

3. What factors should you consider when choosing the right size and type of dowel for a project?

When choosing the right size and type of dowel for a project, you should consider the following factors:

- The thickness of the wood being joined: The diameter of the dowel should be about one-third the thickness of the wood.

- The strength of the joint: The type of wood being joined and the intended use of the joint will determine the strength of the dowel required.

- The appearance of the joint: The type of wood and the grain pattern of the dowel should be considered to ensure a visually appealing joint.

4. What are the steps involved in making a dowel joint?

The steps involved in making a dowel joint are as follows:

- Mark the location of the dowel holes: Use a marking gauge or a center punch to mark the location of the dowel holes on both pieces of wood.

- Drill the dowel holes: Use a drill press to drill the dowel holes. The holes should be slightly smaller than the diameter of the dowels.

- Apply glue to the dowel holes: Apply a thin layer of wood glue to the inside of the dowel holes.

- Insert the dowels: Insert the dowels into the holes and tap them flush with the surface of the wood.

- Clamp the joint: Clamp the joint together and allow the glue to dry.

5. What are some common problems that can occur when making dowel joints and how can they be avoided?

Some common problems that can occur when making dowel joints include:

- The dowel holes are not aligned: This can be avoided by using a drill press or a doweling jig to ensure that the holes are drilled accurately.

- The dowels are too small or too large: This can be avoided by choosing the correct size dowels for the thickness of the wood being joined.

- The joint is not strong enough: This can be avoided by using the correct type of dowel for the intended use of the joint and by applying enough glue to the dowel holes.

6. What are some advanced doweling techniques that can be used to create more complex joints?

Some advanced doweling techniques that can be used to create more complex joints include:

- Doweling with a biscuit joiner: A biscuit joiner can be used to cut slots into the edges of two pieces of wood that are then joined together with dowels.

- Doweling with a dowel jig: A dowel jig can be used to drill dowel holes at precise angles and locations.

- Doweling with a dowel plate: A dowel plate can be used to create multiple dowel joints at once.

7. What are some tips for getting the best results when making dowel joints?

Here are some tips for getting the best results when making dowel joints:

- Use a sharp drill bit and drill press to ensure that the dowel holes are clean and accurate.

- Apply a thin layer of wood glue to the inside of the dowel holes before inserting the dowels.

- Clamp the joint together tightly and allow the glue to dry completely before using the joint.

- Use a doweling jig or a dowel plate to ensure that the dowel holes are aligned and spaced correctly.

- Experiment with different types of dowels and joint configurations to find the best solution for your project.

8. What are some of the advantages of using dowels over other methods of joining wood?

Here are some of the advantages of using dowels over other methods of joining wood:

- Dowels provide a strong and durable joint that can withstand stress and movement.

- Doweling is a relatively simple and straightforward process that can be done with basic tools.

- Dowels can be used to join a variety of different types of wood, including hardwood, softwood, and plywood.

- Dowels can be used to create both visible and invisible joints.

- Dowels are relatively inexpensive and easy to find.

9. What are some of the disadvantages of using dowels?

Here are some of the disadvantages of using dowels:

- Doweling can be time-consuming, especially when making multiple joints.

- Dowels can weaken the wood around the joint if they are not installed correctly.

- Dowels can be difficult to remove if the joint needs to be disassembled.

10. What are some alternative methods of joining wood?

Here are some alternative methods of joining wood:

- Butt joint

- Edge joint

- Miter joint

- Mortise and tenon joint

- Dovetail joint

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Doweler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Doweler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A doweler is responsible for installing and repairing dowels, which are cylindrical rods used to connect and align pieces of wood or metal. They may work in a variety of settings, including construction, woodworking, and manufacturing.

1. Installing Dowels

Dowelers must be able to install dowels accurately and efficiently. This involves using a doweling jig to drill holes and insert dowels into the appropriate locations.

- Use a variety of doweling jigs to drill holes

- Insert dowels into holes and secure them with glue or nails

- Ensure that dowels are aligned properly

2. Repairing Dowels

Dowelers may also be responsible for repairing damaged dowels. This may involve removing old dowels, drilling new holes, and installing new dowels.

- Remove damaged dowels

- Drill new holes

- Install new dowels

3. Inspecting Dowels

Dowelers must be able to inspect dowels for damage or defects. This may involve using a variety of tools, such as a magnifying glass or a microscope.

- Visually inspect dowels for damage or defects

- Use a magnifying glass or a microscope to inspect dowels

- Identify and repair any damaged or defective dowels

4. Other Responsibilities

Other responsibilities of a doweler may include:

- Sharpening dowel bits

- Maintaining doweling equipment

- Cleaning up work area

Interview Tips

A well-prepared interview is key to acing an interview for a doweler role. Here are some tips to help you prepare:

1. Research the company and the position

First, take some time to research the company you’re applying to and the specific doweler position you’re interested in. This will help you understand the company’s culture, goals, and the specific requirements of the role.

- Visit the company’s website

- Read the job description carefully

- Talk to people in your network who work at the company

2. Highlight your skills and experience

In your interview, be sure to highlight your skills and experience that are relevant to the doweler role. If you have experience with doweling jigs, dowel repair, or other related tasks, be sure to mention it.

- Quantify your accomplishments using specific numbers and examples

- Use action verbs to describe your experience

- Tailor your resume and cover letter to the specific job you’re applying for

3. Show your enthusiasm and interest

Finally, don’t forget to show your enthusiasm and interest in the doweler role and the company. This can be done by asking thoughtful questions, listening attentively to the interviewer, and being positive and engaged.

- Ask questions about the company, the role, and the team

- Listen attentively to the interviewer’s questions and answers

- Be positive and enthusiastic throughout the interview

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Doweler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.