Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dragline Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dragline Engineer so you can tailor your answers to impress potential employers.

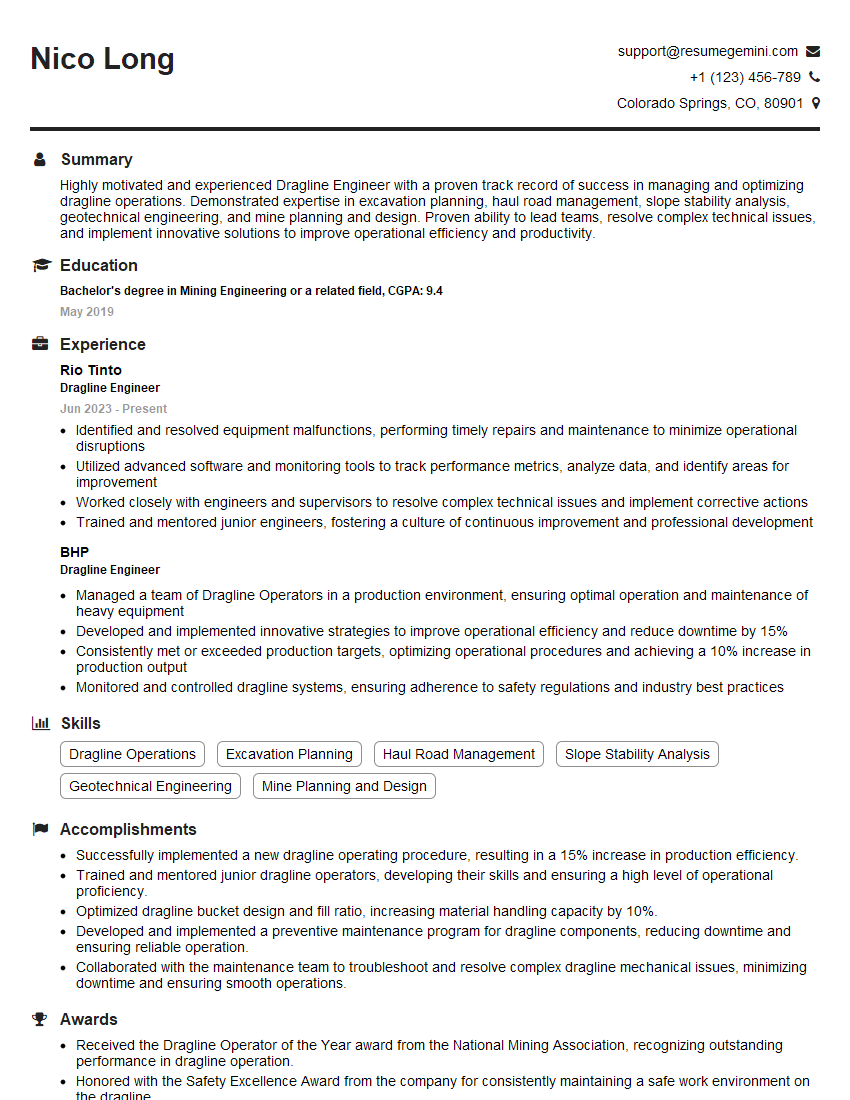

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dragline Engineer

1. Describe the primary responsibilities of a Dragline Engineer in a surface mining operation.

As a Dragline Engineer, my primary responsibilities would include:

- Designing and implementing dragline operating procedures to optimize productivity and efficiency.

- Troubleshooting and resolving equipment malfunctions to minimize downtime.

- Conducting regular inspections and maintenance to ensure the dragline is in safe and optimal working condition.

- Liaising with other engineers, geologists, and supervisors to coordinate mining operations and ensure alignment with production targets.

- Monitoring and analyzing dragline performance data to identify areas for improvement.

2. How would you approach optimizing the bucket fill factor of a dragline?

Bucket Fill Factor Optimization

- Evaluate the current bucket design and make modifications to improve its shape and capacity.

- Adjust the digging angle and travel speed of the dragline to maximize bucket fill.

- Optimize the spoil pile configuration to reduce bucket resistance and improve fill.

- Conduct regular training and evaluation with dragline operators to ensure proper operating techniques.

Data Analysis and Monitoring

- Collect and analyze data on bucket fill factors, digging angles, and travel speeds.

- Use statistical tools to identify trends and areas for improvement.

- Implement continuous monitoring systems to track performance and identify deviations from optimal conditions.

3. Discuss the key parameters to consider when selecting the appropriate dragline for a specific mining operation.

- Material properties: Analyze the characteristics of the material to be excavated, including density, hardness, and abrasiveness.

- Mining conditions: Consider the depth of overburden, thickness of the target seam, and presence of obstacles.

- Production targets: Determine the required output capacity and efficiency to meet production goals.

- Site layout: Evaluate the available space, including spoil pile location, access roads, and infrastructure.

- Environmental considerations: Assess the impact of the dragline operation on the environment, including noise, dust, and water management.

4. Explain the principles and methods involved in dragline structural analysis.

- Finite Element Analysis (FEA): Utilize computer software to model the dragline structure and analyze its behavior under various loads.

- Structural Mechanics: Apply engineering principles to determine stresses, strains, and deflections in critical components.

- Fatigue Analysis: Assess the dragline’s ability to withstand repeated loads and predict its lifespan.

- Non-Destructive Testing (NDT): Conduct inspections using methods such as ultrasonic testing and eddy current testing to identify defects and assess structural integrity.

5. Describe the key components of a dragline electrical system and explain their functions.

- Power Supply: Transformers and switchgear provide the necessary electrical energy to the dragline.

- Motors: Electric motors drive the dragline’s machinery, including the hoist, swing, and propel systems.

- Controllers: Electronic controllers regulate the speed, torque, and direction of the motors.

- Safety Systems: Interlocks and grounding systems ensure safe operation and prevent electrical accidents.

- Monitoring and Diagnostics: Sensors and meters provide real-time data on the electrical system’s performance and enable troubleshooting.

6. How do you ensure the stability of a dragline during operation?

- Ground Conditions Assessment: Evaluate the soil conditions and bearing capacity at the operating site.

- Outrigger Deployment: Extend the dragline’s outriggers to provide additional support and distribute the load.

- Leveling: Ensure that the dragline is leveled properly to prevent uneven loading and potential tipping.

- Monitoring: Use sensors and inclinometers to continuously monitor the dragline’s stability during operation.

- Maintenance: Regularly inspect and maintain the dragline’s structural components to ensure their integrity.

7. Discuss the factors that influence the dragline’s duty cycle and how you would optimize it.

- Material Characteristics: The hardness, abrasiveness, and moisture content of the excavated material impact the digging and hauling time.

- Bucket Size and Fill Factor: A larger bucket or higher fill factor reduces the number of cycles required.

- Haul Distance: The distance from the digging point to the spoil pile affects the overall cycle time.

- Equipment Efficiency: Well-maintained draglines and efficient operating techniques minimize downtime and increase productivity.

Optimization Strategies

- Selecting the optimal bucket size and fill factor for the material being excavated.

- Optimizing the haul distance through effective spoil pile management.

- Implementing preventive maintenance programs to minimize downtime.

- Training dragline operators on best practices to improve efficiency.

8. How would you approach troubleshooting a dragline that is experiencing excessive rope wear?

- Inspect the Rope: Examine the rope for signs of wear, corrosion, or damage.

- Check the Rope Path: Ensure that the rope runs smoothly through the sheaves and pulleys without any obstructions or binding.

- Evaluate the Tensioning System: Inspect the tensioning system to ensure proper tension and alignment.

- Analyze the Operating Conditions: Review the dragline’s operating history and identify any changes or abnormal conditions that may have contributed to the rope wear.

- Consult with Experts: If necessary, consult with rope manufacturers or dragline specialists to obtain additional insights and recommendations.

9. What are the common safety hazards associated with dragline operations and how do you mitigate them?

- Falling Objects: Use personal protective equipment (PPE), implement drop zones, and secure loose materials.

- Electrical Hazards: Ensure proper grounding, lockout/tagout procedures, and electrical safety training.

- Structural Failures: Conduct regular inspections, monitor structural integrity, and follow safe operating practices.

- Pinch Points: Identify and guard pinch points, train operators on safe procedures, and implement lockout/tagout systems.

- Noise and Vibration: Use hearing protection, minimize vibration exposure, and implement noise control measures.

10. How do you stay up-to-date with the latest technologies and innovations in dragline engineering?

- Attend Industry Conferences: Participate in conferences and seminars to learn about new technologies and best practices.

- Read Trade Publications: Subscribe to industry magazines and journals to stay informed about the latest developments.

- Network with Professionals: Connect with other dragline engineers and experts to exchange knowledge and ideas.

- Continuing Education: Take courses or workshops to enhance technical skills and knowledge.

- Manufacturer Training: Attend training programs offered by dragline manufacturers to stay abreast of their latest products and technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dragline Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dragline Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dragline Engineers are responsible for the operation, maintenance, and troubleshooting of draglines, the massive machines used in surface mining operations to excavate and move materials. These engineers are responsible for ensuring the safety and efficiency of these machines, as well as the proper training of their operators. The key job responsibilities of a Dragline Engineer include:

1. Management of Dragline Operations

Dragline Engineers are responsible for planning and coordinating all aspects of dragline operations, including the scheduling, manpower, and equipment necessary for efficient mining. They must ensure that the dragline is operated in a safe and productive manner, in accordance with all applicable regulations and standards.

2. Supervision of Dragline Operators

Dragline Engineers are responsible for supervising and training dragline operators, ensuring that they possess the necessary skills and knowledge to operate the dragline safely and efficiently. They must provide ongoing training and mentorship to their operators, and provide them with the support and resources necessary to succeed in their roles.

3. Maintenance and Troubleshooting

Dragline Engineers are responsible for maintaining and troubleshooting the dragline, performing scheduled inspections and repairs to ensure optimal performance. They must be able to diagnose and resolve mechanical, electrical, and hydraulic issues quickly and efficiently, minimizing downtime and maximizing productivity.

4. Site Management

Dragline Engineers are responsible for managing the dragline site, ensuring that it is safe, clean, and organized. They must work closely with other engineers, technicians, and managers to coordinate activities and ensure that the dragline is operating in a manner that minimizes environmental impact.

Interview Tips

A successful interview for a Dragline Engineer position requires a combination of technical expertise, communication skills, and problem-solving abilities. To ace the interview, candidates should prepare thoroughly and be ready to demonstrate their knowledge and experience in the field. Here are some tips to help candidates succeed in their interviews:

1. Research the Company and the Role

Before the interview, it is essential to conduct thorough research on the company and the specific role you are applying for. Familiarize yourself with the company’s history, products or services, and the industry in which they operate. Research the job description carefully, paying attention to the required skills, experience, and responsibilities.

2. Highlight Technical Expertise

Dragline Engineers must possess a strong understanding of dragline operations, maintenance, and troubleshooting. In the interview, be sure to emphasize your technical expertise in these areas. Provide specific examples of your work experience, such as times when you diagnosed and resolved complex technical issues.

3. Demonstrate Problem-Solving Abilities

Problem-solving is a critical skill for Dragline Engineers. During the interview, you may be asked to describe how you would approach a specific problem or challenge related to dragline operations. Be prepared to provide detailed and well-reasoned answers, demonstrating your analytical and problem-solving capabilities.

4. Emphasize Safety and Environmental Awareness

Safety and environmental awareness are paramount in dragline operations. In the interview, highlight your commitment to safety and your understanding of environmental regulations. Discuss your experience in implementing safety protocols and minimizing environmental impact at previous workplaces.

5. Prepare Questions for the Interviewers

Asking insightful questions at the end of the interview shows that you are engaged and interested in the position. Prepare thoughtful questions about the company’s operations, the role’s responsibilities, or the industry outlook. This demonstrates your enthusiasm and eagerness to learn more about the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dragline Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!