Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dragline Oiler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dragline Oiler so you can tailor your answers to impress potential employers.

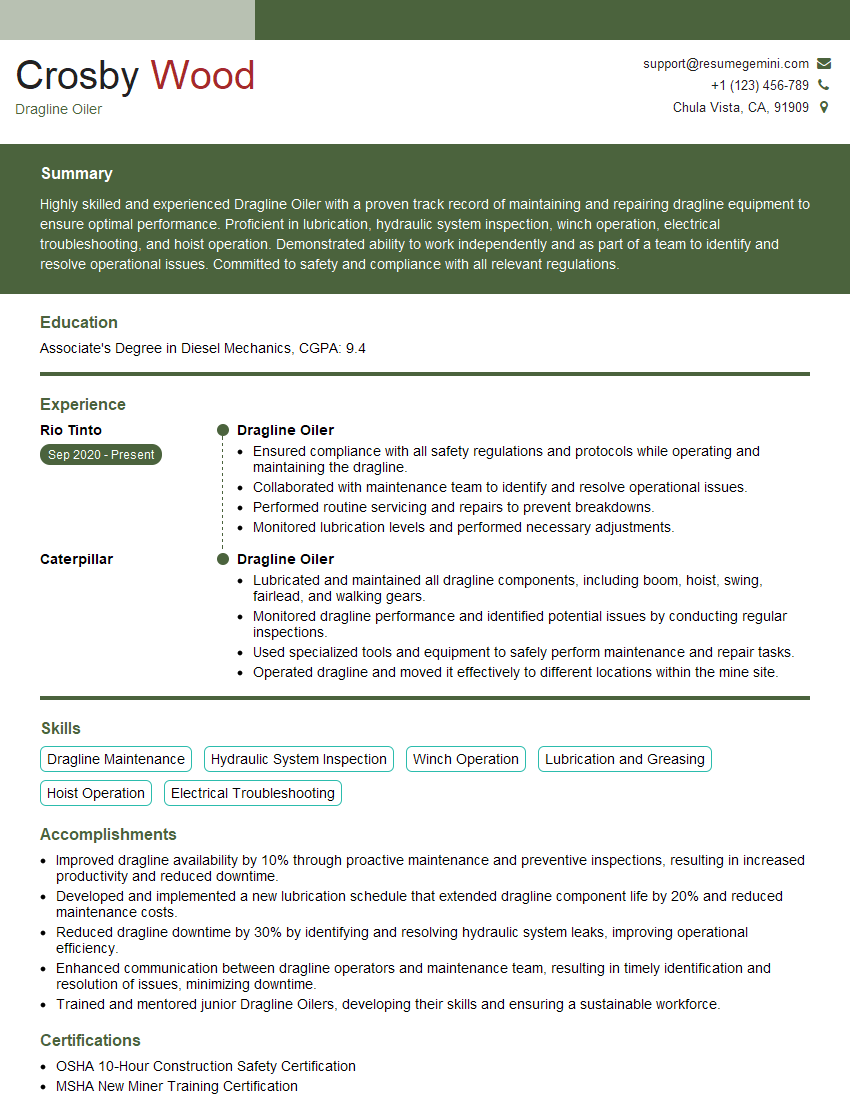

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dragline Oiler

1. Describe the key responsibilities of a Dragline Oiler?

The primary responsibilities of a Dragline Oiler include:

- Lubricating and greasing draglines and associated equipment to maintain optimal performance and prevent breakdowns.

- Monitoring equipment for any signs of wear or damage, reporting any issues promptly to ensure timely repairs.

- Maintaining a clean and organized work area, ensuring a safe and efficient work environment.

- Assisting with minor repairs and maintenance tasks as needed, contributing to overall equipment uptime.

- Following safety protocols and procedures, adhering to established standards to minimize risks.

2. Explain the different types of lubricants used on draglines and their applications.

Lubricating Dragline Components

- Grease: Heavy-duty grease is used to lubricate bearings, gears, and other moving parts, reducing friction and wear.

- Oil: Oil is used to lubricate chains, cables, and other components that require a fluid lubricant.

Lubricating Equipment Types

- Dragline: Grease and oil are used to lubricate the dragline’s gears, bearings, chains, and cables.

- Swing Motor: Grease is used to lubricate the swing motor’s gears and bearings.

- Hoist Motor: Grease is used to lubricate the hoist motor’s gears and bearings.

3. How do you identify and troubleshoot common problems with draglines?

- Unusual noises: Grinding, squealing, or knocking sounds can indicate problems with gears, bearings, or cables.

- Excessive vibration: This can be caused by misalignment, worn components, or loose connections.

- Reduced power: This can indicate problems with the engine, hydraulic system, or electrical components.

- Oil or grease leaks: These can indicate worn seals or damaged components, requiring immediate attention.

- Electrical issues: Faulty wiring, loose connections, or damaged components can cause electrical problems.

Troubleshooting Process

- Observe the symptoms and gather information.

- Inspect the equipment for visible signs of damage or wear.

- Consult the dragline’s maintenance manual for specific troubleshooting procedures.

- Use diagnostic tools to further identify the root cause of the problem.

- Repair or replace damaged components as necessary.

4. What safety precautions should be taken when working on draglines?

- Wear appropriate personal protective equipment (PPE), including hardhat, safety glasses, gloves, and hearing protection.

- Lock out and tag out equipment before performing any maintenance or repairs.

- Be aware of the machine’s swing radius and keep a safe distance from moving parts.

- Use proper lifting techniques when handling heavy components.

- Follow established work procedures and safety protocols.

- Inspect equipment regularly for any potential hazards.

- Report any unsafe conditions or equipment malfunctions immediately.

5. Describe the maintenance procedures for draglines, including daily, weekly, and monthly tasks.

Daily Maintenance

- Check oil and grease levels.

- Inspect for leaks.

- Clean and remove debris.

Weekly Maintenance

- Lubricate moving parts.

- Inspect cables and chains.

- Check electrical connections.

Monthly Maintenance

- Perform a thorough inspection of the dragline.

- Replace worn or damaged components.

- Conduct oil and filter changes.

- Calibrate sensors and instruments.

6. How do you ensure the proper tension of dragline cables and chains?

- Use a tension gauge to measure the tension of the cables and chains.

- Adjust the tension by tightening or loosening the turnbuckles or adjusting the hydraulic tensioning system.

- Follow the manufacturer’s recommended tension specifications.

- Regularly inspect cables and chains for signs of wear or damage.

7. Explain the importance of maintaining proper oil levels in draglines.

- Lubrication: Oil provides lubrication to moving parts, reducing friction and wear.

- Cooling: Oil helps to dissipate heat from components, preventing overheating.

- Corrosion protection: Oil forms a protective layer on metal surfaces, preventing corrosion.

- Power transmission: Oil is used in hydraulic systems to transmit power and operate various components.

Consequences of Improper Oil Levels

- Increased wear and tear on components.

- Overheating and potential damage to equipment.

- Reduced efficiency and power output.

- Increased risk of breakdowns and downtime.

8. What are the different types of sensors used on draglines and their functions?

- Position sensors: Monitor the position of the dragline’s boom, bucket, and swing.

- Pressure sensors: Measure the pressure of hydraulic systems, ensuring proper operation.

- Temperature sensors: Monitor the temperature of critical components, preventing overheating.

- Load sensors: Measure the weight of the dragline’s load, ensuring safe operation.

- Vibration sensors: Detect excessive vibration, indicating potential problems with equipment.

9. How do you maintain and calibrate sensors on draglines?

- Regular cleaning: Remove dust, dirt, and debris to ensure proper operation.

- Inspection: Check for any visible damage or wear.

- Calibration: Use specialized equipment to calibrate sensors according to manufacturer specifications.

- Testing: Perform functional tests to verify accuracy and reliability.

- Recordkeeping: Maintain records of maintenance and calibration activities.

10. Explain the role of a Dragline Oiler in contributing to workplace safety and environmental protection.

Workplace Safety

- Following safety protocols and procedures.

- Identifying and reporting potential hazards.

- Maintaining a clean and organized work area.

Environmental Protection

- Properly disposing of lubricants and other waste materials.

- Preventing oil and grease leaks.

- Adhering to environmental regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dragline Oiler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dragline Oiler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dragline Oilers are responsible for maintaining and servicing draglines, which are large excavating machines used in mining operations. Their key responsibilities include:

1. Lubrication and Maintenance

Regularly lubricate all moving parts of the dragline, including gears, bearings, and chains. Ensure that all lubrication points are properly identified and receive the correct type and amount of lubricant. Inspect and adjust chains and cables to maintain proper tension and alignment.

- Conduct regular visual inspections of the dragline to identify any potential problems and take corrective action.

- Perform minor repairs and adjustments as needed, such as replacing worn parts or tightening bolts.

2. Fueling and Fluid Maintenance

Monitor fuel and fluid levels regularly and add fuel and fluids as necessary. Check hydraulic systems for leaks and ensure proper fluid levels. Change filters and clean or replace fluid reservoirs as per the manufacturer’s recommendations.

- Keep accurate records of fuel and fluid consumption to ensure proper inventory management.

- Monitor the performance of the dragline and identify any changes that may indicate potential problems.

3. Troubleshooting and Repairs

Troubleshoot problems with the dragline, such as engine malfunctions, hydraulic leaks, or electrical issues. Diagnose the cause of the problem and perform repairs or coordinate with mechanics for more complex repairs.

- Stay up-to-date on maintenance and repair procedures and follow manufacturer’s guidelines.

- Order and maintain an inventory of spare parts and supplies to ensure timely repairs.

4. Safety Compliance

Adhere to all safety regulations and procedures while servicing the dragline. Wear appropriate personal protective equipment (PPE), such as safety glasses, hard hats, and gloves. Inspect and ensure that all safety devices on the dragline are in proper working order.

- Maintain a clean and organized work area around the dragline.

- Communicate with other team members and supervisors to ensure coordination and safety during maintenance and repair operations.

Interview Tips

Preparing for a Dragline Oiler interview requires a combination of technical knowledge, practical experience, and a strong understanding of safety procedures. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the mining company and the specific role of a Dragline Oiler. Understand the company’s size, operations, and safety culture. Review the job description carefully to identify the key responsibilities and qualifications.

- Practice answering common interview questions related to dragline maintenance and troubleshooting.

- Prepare questions to ask the interviewer about the position, the team, and the company’s safety policies.

2. Highlight Your Technical Skills

Emphasize your experience in lubrication, fluid maintenance, and troubleshooting of heavy machinery. Quantify your accomplishments whenever possible, providing specific examples of how you effectively maintained and repaired draglines or similar equipment.

- Be prepared to discuss your knowledge of hydraulic systems, engines, and electrical components.

- Explain how you stay updated on industry best practices and manufacturer’s recommendations for dragline maintenance.

3. Demonstrate Your Safety Mindset

Safety is paramount in mining operations. Highlight your commitment to following safety regulations and procedures. Describe your experience in identifying and mitigating potential hazards, and your understanding of the importance of proper PPE and safety inspections.

- Share examples of how you have proactively identified and resolved safety issues in previous roles.

- Explain how you maintain a clean and organized work area, and communicate effectively with others to ensure safety on the job site.

4. Show Your Dedication to Teamwork

Dragline Oilers often work as part of a team of mechanics and operators. Emphasize your ability to collaborate effectively, communicate clearly, and support your team members. Highlight your experience in coordinating with others to ensure timely repairs and maintain a productive work environment.

- Provide examples of how you have successfully worked in a team to resolve complex maintenance issues.

- Explain how you communicate effectively with operators and supervisors to ensure smooth operations.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Dragline Oiler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Dragline Oiler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.