Feeling lost in a sea of interview questions? Landed that dream interview for Draw Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Draw Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

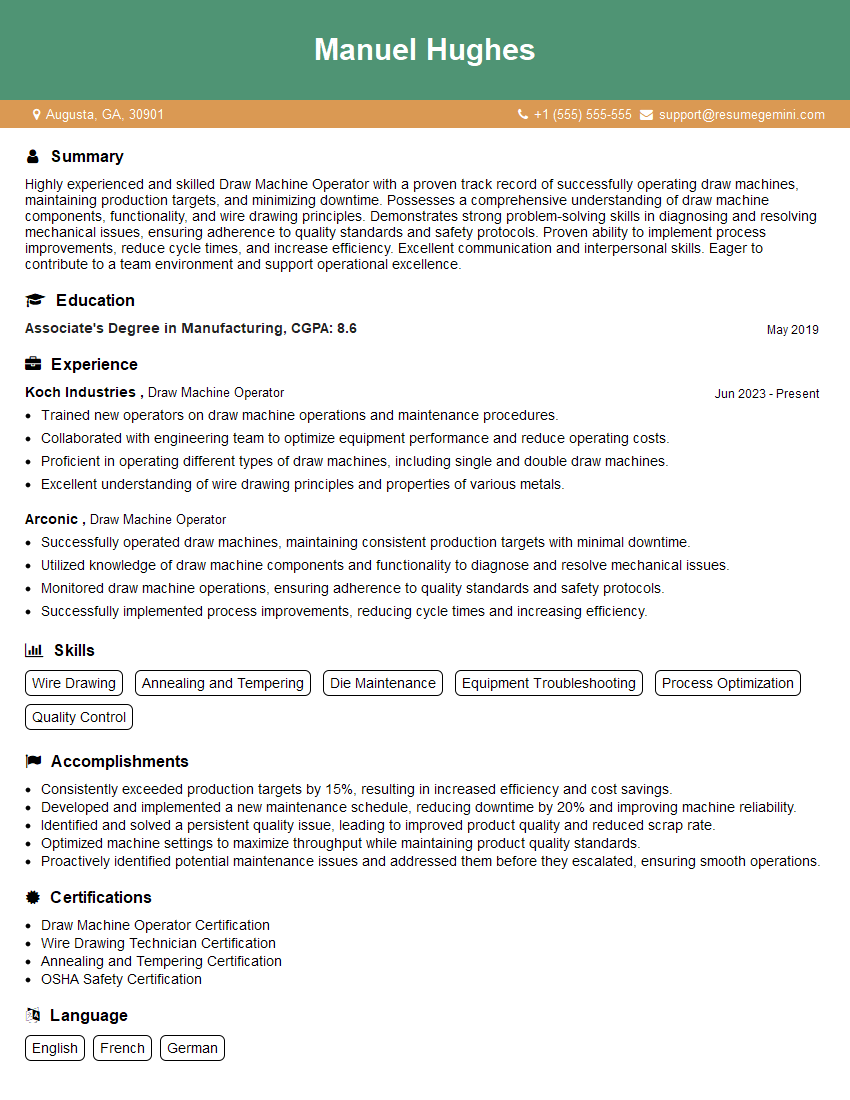

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Draw Machine Operator

1. What are the different types of draw machines and their applications?

- Batch Draw Machines: Used for producing large batches of wires, bars, or tubes, such as in the automotive and construction industries.

- Continuous Draw Machines: Designed for continuous production of wire, enabling high-volume, high-speed manufacturing of wires for electrical cables, springs, and other applications.

- Fine Wire Draw Machines: Specialized for drawing extremely thin and precise wires, typically used in microelectronics, medical devices, and aerospace applications.

- Multi-Wire Draw Machines: Capable of drawing multiple wires simultaneously, increasing production efficiency and reducing manufacturing time.

2. Describe the key components of a draw machine and their functions.

Die Box

- Houses the drawing die, which shapes the wire or bar during the drawing process.

Capstan

- Grips and pulls the wire or bar through the die box.

- Regulates the drawing speed and tension.

Spooler

- Collects the drawn wire or bar onto a spool.

- Ensures proper winding and prevents tangles.

Control Panel

- Monitors and controls the machine’s parameters, such as speed, tension, and temperature.

- Provides operator interface and diagnostic information.

3. How do you calculate the reduction ratio of a draw machine?

The reduction ratio is a measure of how much the wire or bar is reduced in cross-sectional area during the drawing process. It is calculated as:

Reduction Ratio = (Initial Cross-Sectional Area) / (Final Cross-Sectional Area)

- The initial cross-sectional area is the area of the wire or bar before drawing.

- The final cross-sectional area is the area of the wire or bar after drawing.

4. What are some common defects that can occur during wire drawing and how do you prevent them?

- Surface Scratches: Caused by improper die maintenance or contamination. Prevented by using clean dies and lubricants.

- Elongated Grains: Result from excessive reduction ratio. Prevented by using proper reduction ratios and annealing the wire.

- Internal Voids: Caused by air entrapment. Prevented by using proper drawing lubricants and reducing the drawing speed.

- Ovality: Occurs when the drawing force is uneven. Prevented by ensuring proper alignment of the die and capstan.

5. How do you maintain and calibrate a draw machine to ensure optimal performance?

- Regular Cleaning: Remove dirt, debris, and lubricants from the machine to prevent contamination.

- Die Maintenance: Inspect and sharpen dies regularly to prevent surface defects and ensure accurate wire dimensions.

- Lubrication: Use proper lubricants to reduce friction and prevent wear on the machine components.

- Calibration: Use calibration tools and procedures to ensure accuracy of the machine’s measurements and settings.

6. What are the safety precautions you must observe when operating a draw machine?

- Wear appropriate safety gear, including gloves, eye protection, and earplugs.

- Keep hands and clothing away from moving parts.

- Never attempt to clear jams or adjust the machine while it is running.

- Be aware of potential pinch points and tripping hazards.

7. What factors affect the selection of the drawing die for a particular wire diameter and material?

- Wire Material: Die materials and design must be compatible with the wire material’s properties.

- Wire Diameter: Die hole diameter must match the desired final wire diameter.

- Reduction Ratio: Die design should allow for the desired reduction ratio while minimizing defects.

- Production Rate: Die materials and design should be suitable for the desired production speed.

8. How do you set up and operate a draw machine for a new wire material?

- Select the appropriate die: Based on the wire material and desired diameter.

- Lubricate the machine components: Use proper lubricants for the wire material.

- Set the machine parameters: Based on the desired drawing speed and tension.

- Start the machine and monitor the wire quality: Adjust parameters as needed.

9. How do you troubleshoot common draw machine problems, such as wire breakage or uneven diameter?

- Wire Breakage: Check for jammed dies, improper lubrication, or excessive reduction ratio.

- Uneven Diameter: Check for worn or misaligned dies, improper die setup, or fluctuations in drawing tension.

- Surface Defects: Check for contamination, worn dies, or improper lubrication.

- Excessive Vibration: Check for loose components, misalignment, or worn bearings.

10. What quality control procedures do you follow to ensure the production of high-quality drawn wire?

- Raw Material Inspection: Check incoming wire for defects and dimensional accuracy.

- In-Process Inspection: Monitor wire quality, process parameters, and machine performance during drawing.

- Final Product Inspection: Conduct dimensional measurements, surface inspections, and mechanical testing to ensure product quality.

- Regular Calibration: Ensure accuracy of measuring devices and machine settings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Draw Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Draw Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Draw Machine Operator is responsible for operating a draw machine, a specialized piece of equipment used in the manufacturing of wire and fiber. They ensure the smooth and efficient operation of the machine, monitor production quality, and perform maintenance and repairs as needed.

1. Machine Operation

Operate and control the draw machine, including setting up, starting, stopping, and adjusting machine parameters.

- Monitor the machine’s performance, including speed, temperature, and tension.

- Make adjustments to machine settings to optimize production quality and efficiency.

2. Production Monitoring

Monitor the production process to ensure that the wire or fiber meets the required specifications.

- Inspect the finished product for defects and inconsistencies.

- Maintain production records and report any issues or downtime to supervisors.

3. Maintenance and Repairs

Perform routine maintenance and repairs on the draw machine.

- Clean and lubricate the machine’s components.

- Replace worn or damaged parts.

4. Troubleshooting

Troubleshoot and resolve any operational issues that may arise with the draw machine.

- Diagnose the cause of machine malfunctions.

- Implement corrective actions to restore the machine to optimal operating condition.

Interview Tips

Preparing adequately for an interview can greatly enhance your chances of success. Here are some interview tips and hacks to help you ace your Draw Machine Operator interview:

1. Research the Company and Position

Take the time to thoroughly research the company and the specific Draw Machine Operator position you are applying for. This will help you understand the company’s culture, values, and the key requirements of the role.

- Visit the company’s website and social media pages.

- Read industry news and articles related to draw machine operations.

2. Practice Answering Common Interview Questions

Anticipate and prepare for common interview questions related to your skills, experience, and qualifications. Practice answering these questions clearly and concisely, highlighting your relevant abilities and accomplishments.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

- Quantify your achievements whenever possible using specific metrics and data.

3. Highlight Your Technical Skills

Emphasize your technical skills and knowledge of draw machine operations, including your experience with specific types of machines and materials.

- Describe your expertise in setting up, operating, and maintaining draw machines.

- Discuss your understanding of wire and fiber properties and how they affect the draw process.

4. Demonstrate Your Problem-Solving Abilities

Interviewers often seek candidates who can effectively troubleshoot and resolve problems. Showcase your problem-solving skills by providing examples of how you have successfully diagnosed and fixed issues with draw machines in the past.

- Use specific examples to illustrate your analytical and critical thinking abilities.

- Explain the steps you took to identify the root cause of the problem and implement a solution.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Draw Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!