Are you gearing up for a career in Drawbench Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Drawbench Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

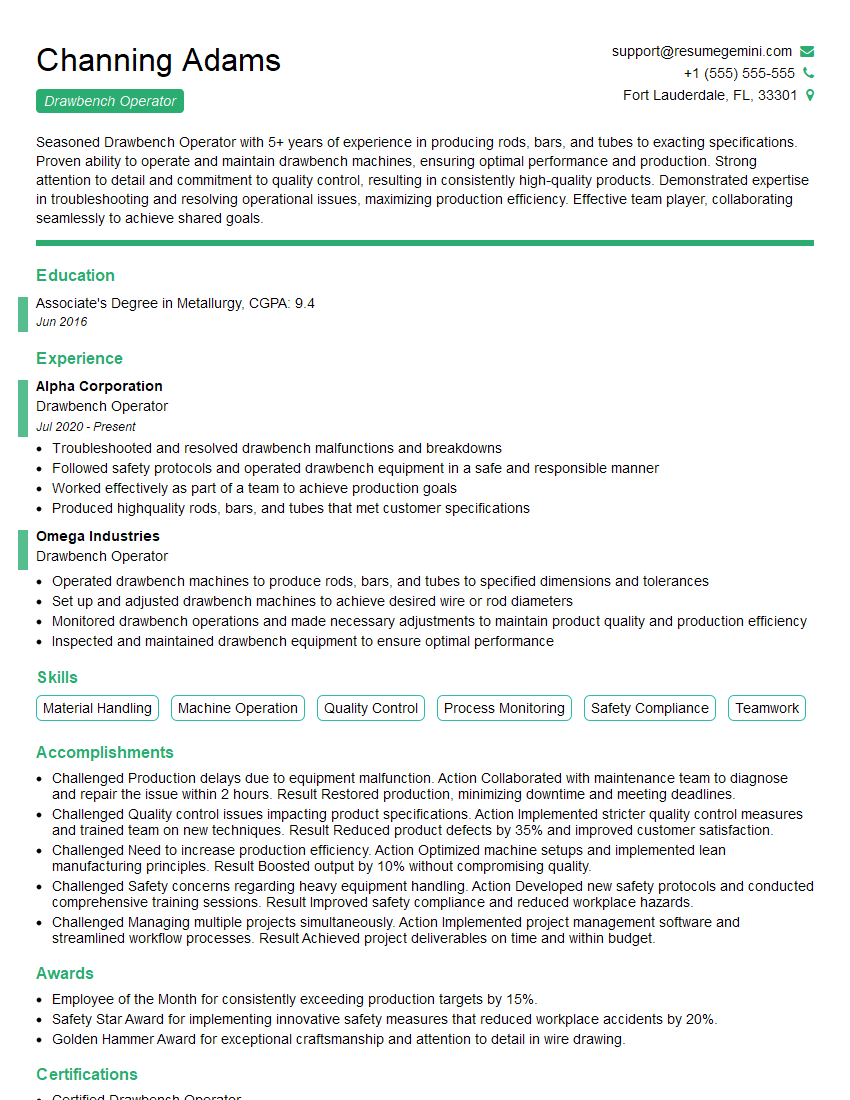

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drawbench Operator

1. What are the key responsibilities of a Drawbench Operator?

- Operate a drawbench machine to produce wire, rods, and bars with precise dimensions and mechanical properties.

- Monitor the machine and make adjustments to maintain the desired quality and output.

- Set up and calibrate equipment, including dies, tooling, and gauges.

- Inspect finished products and maintain quality standards.

- Load and unload heavy materials onto the machine.

2. Describe the different types of drawbenches and their uses?

Types of Drawbenches:

- Horizontal drawbenches are used for drawing wire, rods, and tubes.

- Vertical drawbenches are used for drawing heavier materials, such as bars and shapes.

- Continuous drawbenches are used for high-volume production of wire and small rods.

Uses of Drawbenches:

- Producing wire for electrical cables, springs, and other applications.

- Drawing rods for automotive components, construction, and medical devices.

- Creating bars and shapes for a variety of industrial and consumer products.

3. What are the safety precautions that must be followed when operating a drawbench?

- Wear appropriate personal protective equipment, including safety glasses, gloves, and earplugs.

- Never stand directly in line with the drawbench.

- Keep hands and loose clothing away from moving parts.

- Inspect the machine and tooling regularly for any damage or wear.

- Follow all lockout/tagout procedures before performing maintenance or repairs.

4. How do you calculate the draw force required to produce a specific reduction in cross-sectional area?

- Determine the original cross-sectional area (Ao) and final cross-sectional area (Af).

- Calculate the reduction in cross-sectional area (R): R = (Ao – Af) / Ao.

- Use the following formula: Draw Force = Yield Strength x R x Af.

5. What are the different types of lubricants used in drawbench operations and their advantages?

- Oil-based lubricants provide good lubrication and corrosion protection.

- Water-based lubricants are environmentally friendly and can be used for high-speed operations.

- Dry lubricants, such as graphite, reduce friction and are suitable for high-temperature applications.

- Chemical lubricants form a protective layer on the metal surface and enhance surface finish.

6. How do you adjust the drawbench parameters to achieve the desired product dimensions and properties?

- Adjust the die size to control the final product diameter or cross-sectional shape.

- Set the draw speed to optimize material flow and prevent defects.

- Control the tension on the material to achieve the desired strength and elongation.

- Adjust the lubrication system to minimize friction and improve surface finish.

7. How do you troubleshoot common problems that may occur during drawbench operations?

- Surface defects: Adjust lubrication, check die cleanliness, and inspect for material defects.

- Dimensional inaccuracies: Recalibrate equipment, check die dimensions, and adjust draw parameters.

- Breakages: Inspect material for defects, adjust tension settings, and check machine alignment.

- Lubrication issues: Check lubricant level, viscosity, and compatibility with the material.

8. What is the importance of maintenance and calibration for drawbench equipment?

- Regular maintenance prevents breakdowns and extends equipment life.

- Calibration ensures accurate dimensions and product quality.

- Proper maintenance and calibration reduce downtime and increase productivity.

9. How do you work effectively as part of a team in a manufacturing environment?

- Communicate clearly and collaborate with other team members.

- Share knowledge and support colleagues to achieve common goals.

- Maintain a positive and productive work environment.

- Follow safety protocols and contribute to a safe workplace.

10. How do you stay up-to-date with the latest advancements in drawbench technology and industry best practices?

- Attend industry conferences and workshops.

- Read technical publications and articles.

- Consult with manufacturers and equipment suppliers.

- Seek opportunities for professional development and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drawbench Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drawbench Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drawbench Operators play a crucial role in manufacturing processes, operating drawbenches to shape and elongate metal materials.

1. Drawbench Operation

- Set up and operate drawbenches, ensuring proper alignment and tension.

- Monitor drawbench performance, adjusting variables such as speed, tension, and lubrication.

- Troubleshoot and resolve operational issues efficiently.

2. Material Handling

- Load and unload metal rods or tubes onto the drawbench.

- Inspect and prepare materials for drawing, ensuring they meet specifications.

- Bundle and package finished products according to customer requirements.

3. Process Control

- Monitor process parameters, including temperature, pressure, and speed.

- Make necessary adjustments to maintain product quality and efficiency.

- Maintain and calibrate drawbench equipment, ensuring accuracy and reliability.

4. Quality Control

- Inspect finished products for defects, such as cracks, surface imperfections, and dimensional accuracy.

- Report and document any quality issues promptly.

- Adhere to established quality standards and procedures.

Interview Tips

To ace your interview for the Drawbench Operator position, consider the following tips:

1. Research the Company and Industry

- Learn about the company’s products, services, and industry standing.

- Demonstrate your understanding of the manufacturing process involving drawbenches.

2. Practice Common Interview Questions

- “Tell us about your experience operating drawbenches.”

- “How do you ensure product quality and meet customer specifications?”

- “Describe a time when you had to troubleshoot and resolve an equipment issue.”

3. Highlight Your Skills and Abilities

- Emphasize your technical abilities, such as drawbench setup and operation.

- Showcase your attention to detail, precision, and quality-oriented mindset.

- Demonstrate your ability to work independently and as part of a team.

4. Prepare Questions for the Interviewer

- “Could you elaborate on the company’s production goals and quality standards?”

- “What are the key challenges and opportunities in this role?”

- “What is the company’s approach to employee training and development?”

5. Be Professional and Confident

- Dress appropriately and arrive on time for the interview.

- Maintain eye contact, speak clearly, and present yourself with confidence.

- Be enthusiastic about the opportunity and express your interest in the company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Drawbench Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.