Are you gearing up for a career in Drawing Kiln Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Drawing Kiln Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drawing Kiln Operator

1. Can you explain the process of drawing a kiln?

answer:

- It involves carefully removing fired ceramic ware from a kiln using specialized tools and techniques to prevent damage to the pieces and the kiln.

- The process requires skill, attention to detail, and an understanding of the kiln’s operation and the properties of the fired ware.

2. What are the key indicators that a kiln is ready to be drawn?

Temperature

- The kiln’s internal temperature should have cooled down to a safe level, typically below 150°C (300°F).

Time

- Sufficient time should have passed since the kiln was turned off to allow the ware to cool and settle.

Appearance

- The peephole or pyrometer should show that the ware is no longer glowing.

3. Describe the proper procedures for opening and cooling a kiln.

answer:

- Wear appropriate safety gear, including gloves, safety glasses, and a respirator if necessary.

- Open the kiln door slowly and carefully to avoid thermal shock to the ware.

- Allow the kiln to cool down gradually by leaving the door slightly open.

- Use a fan or other ventilation system to accelerate the cooling process if needed.

4. What are the potential hazards associated with drawing kilns, and how can they be mitigated?

answer:

- Thermal shock: Caused by sudden temperature changes, can be mitigated by opening the kiln door slowly and cooling the ware gradually.

- Fumes and gases: Released during the cooling process, can be mitigated by using a respirator and ensuring adequate ventilation.

- Sharp edges: On the ware or kiln furniture, can be mitigated by wearing gloves and handling the ware carefully.

- Heavy lifting: Involved in moving the ware, can be mitigated by using proper lifting techniques and seeking assistance when necessary.

5. Explain the importance of kiln furniture in drawing kilns.

Support and protection

- Kiln furniture provides support and protection for the ware during firing and cooling, preventing damage and ensuring even heating.

Proper placement

- Proper placement of kiln furniture allows for optimal airflow and heat distribution, ensuring uniform firing and cooling.

Material selection

- The choice of kiln furniture material depends on the firing temperature and the type of ware being fired.

6. How do you determine the appropriate cooling rate for different types of ceramics?

answer:

- Consider the thermal expansion and contraction properties of the clay body.

- Take into account the thickness and complexity of the ware.

- Follow the manufacturer’s recommendations for the specific glaze or clay being used.

7. What are the common defects that can occur during the drawing process, and how can they be prevented?

answer:

- Cracking: Caused by uneven cooling or thermal shock, can be prevented by opening the kiln door slowly and cooling the ware gradually.

- Warping: Caused by uneven shrinkage during cooling, can be prevented by using proper kiln furniture and ensuring uniform heating and cooling.

- Glaze defects: Such as pinholing or crawling, can be prevented by using the correct glaze formulation and firing schedule.

8. How do you maintain and calibrate the equipment used in drawing kilns?

Regular inspections

- Regularly inspect the kiln, thermocouples, and other equipment for signs of wear or damage.

Calibration

- Calibrate the kiln’s temperature controller according to the manufacturer’s instructions to ensure accurate temperature readings.

Maintenance

- Perform necessary maintenance tasks, such as cleaning and lubricating, to keep the equipment in good working order.

9. Explain the importance of following safety protocols when drawing kilns.

answer:

- Following safety protocols helps prevent accidents and injuries, such as burns, cuts, or exposure to hazardous fumes.

- It ensures compliance with workplace regulations and standards.

- It creates a safe work environment for employees and others in the vicinity.

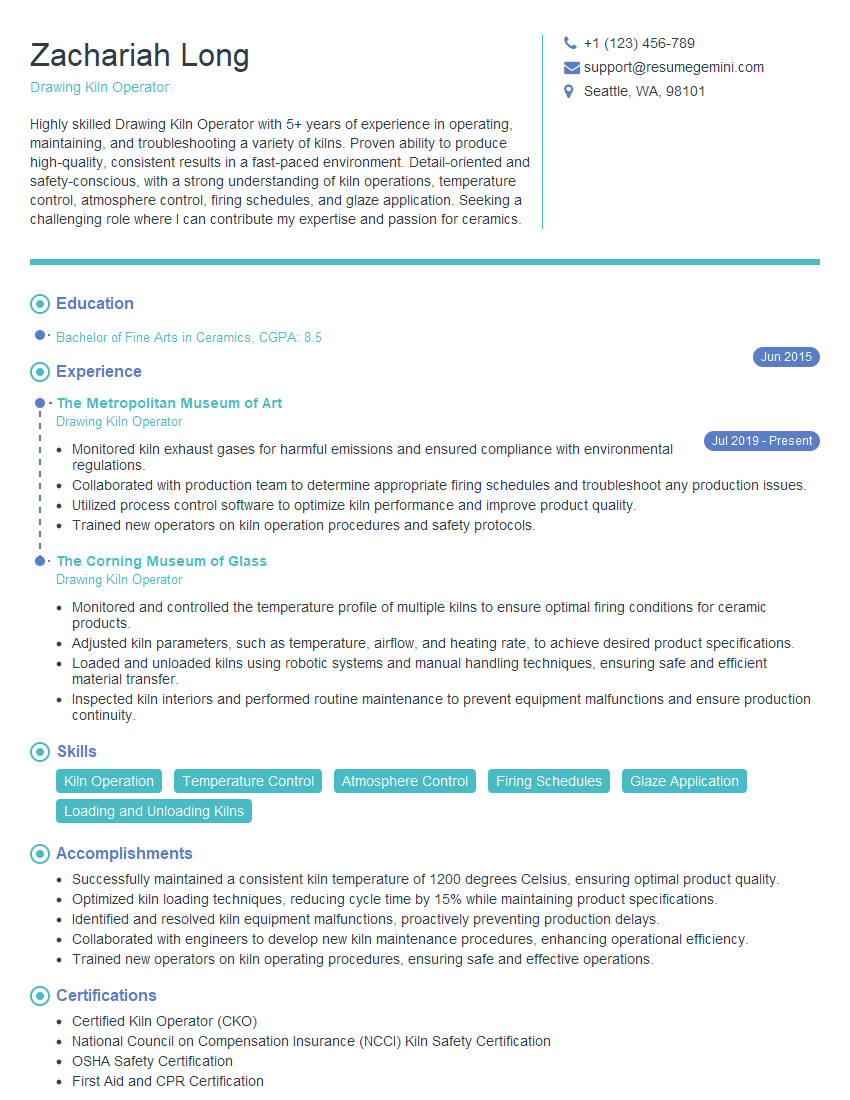

10. Describe your experience and qualifications for the role of Drawing Kiln Operator.

answer:

- Highlight relevant experience in drawing kilns, including specific responsibilities and accomplishments.

- Emphasize skills and knowledge in kiln operation, temperature control, and ware handling.

- Mention any certifications or training related to the role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drawing Kiln Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drawing Kiln Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drawing Kiln Operators play a crucial role in the manufacturing process, ensuring the smooth operation of kilns used to produce various materials such as ceramics, bricks, and glass.

1. Kiln Operation

The primary responsibility of Drawing Kiln Operators is to monitor and control the operation of kilns, ensuring that they maintain optimal temperature and firing conditions.

- Maintain accurate temperature readings and make adjustments as needed to achieve desired firing cycles.

- Monitor kiln atmosphere, including oxygen levels and humidity, to prevent defects in the final product.

2. Loading and Unloading

Drawing Kiln Operators are responsible for loading and unloading kilns, ensuring the safe and efficient movement of materials.

- Properly load kilns with materials, following specified stacking patterns and procedures.

- Unload fired materials from kilns using appropriate equipment, such as forklifts or conveyors.

3. Quality Control

To ensure the quality of the final product, Drawing Kiln Operators perform regular inspections and quality checks.

- Monitor fired materials for defects, such as cracks, discoloration, or uneven firing.

- Maintain records of kiln operation and quality checks for future reference.

4. Equipment Maintenance

Drawing Kiln Operators are responsible for maintaining the kilns and associated equipment in good working order.

- Perform routine maintenance tasks, such as cleaning, lubrication, and calibration.

- Identify and report any equipment malfunctions or issues promptly to ensure timely repairs.

Interview Tips

To ace an interview for a Drawing Kiln Operator position, candidates should be well-prepared and demonstrate their knowledge and skills in the following areas:

1. Technical Expertise

Candidates should have a strong understanding of kiln operation, including temperature control, firing cycles, and quality control procedures.

- Provide specific examples of how you have successfully operated and maintained kilns in previous roles.

- Discuss your knowledge of different types of kilns and their applications.

2. Safety and Attention to Detail

Drawing Kiln Operators must prioritize safety and pay close attention to detail to ensure proper kiln operation and product quality.

- Demonstrate your understanding of safety protocols and your ability to work safely in a manufacturing environment.

- Provide examples of how you have maintained a high level of attention to detail in previous roles.

3. Problem-Solving Abilities

Candidates should possess problem-solving skills to address potential issues with kiln operation and equipment maintenance.

- Describe a situation where you encountered a problem with a kiln and how you resolved it.

- Explain your approach to troubleshooting and identifying solutions.

4. Communication and Teamwork

Drawing Kiln Operators often work as part of a team and need to effectively communicate with supervisors and colleagues.

- Highlight your ability to work effectively in a team environment.

- Provide examples of how you have communicated effectively with supervisors and colleagues.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drawing Kiln Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.