Are you gearing up for a career in Dredge Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Dredge Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

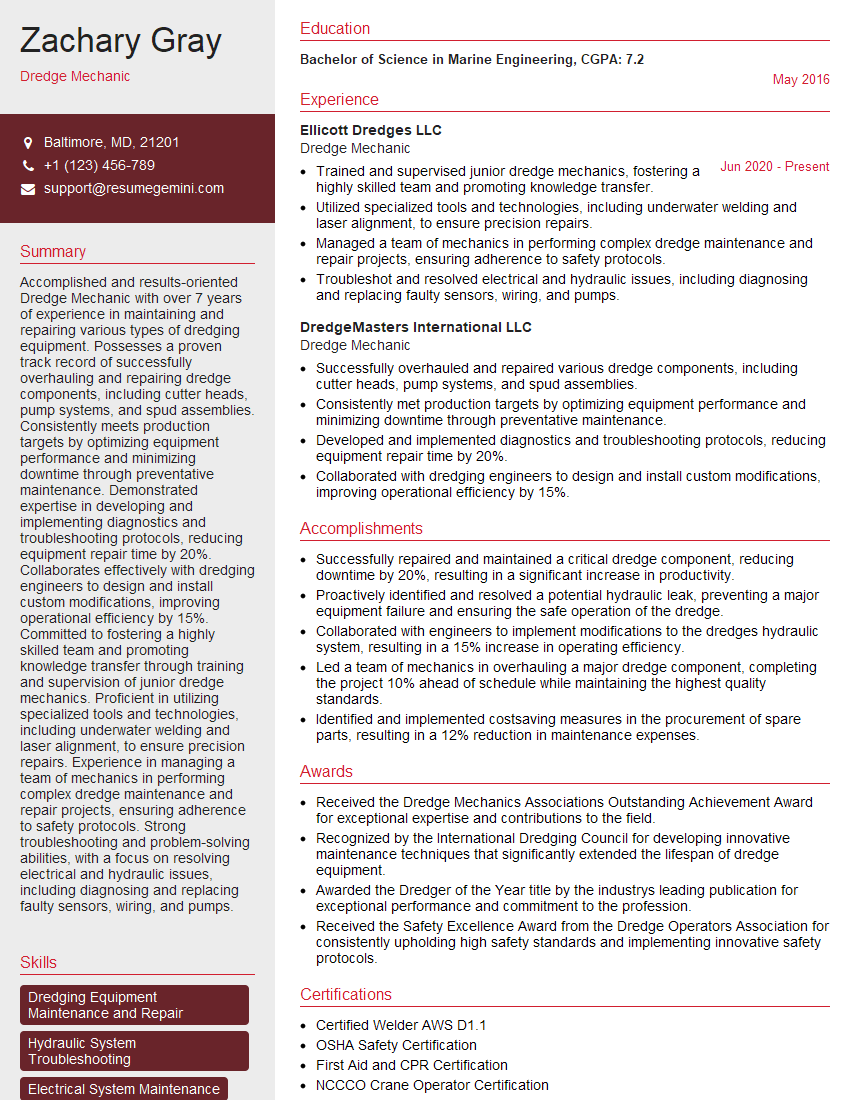

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dredge Mechanic

1. Explain the different types of dredges and their applications?

There are various types of dredges, each designed for specific applications. Here are some common types:

- Trailing Suction Hopper Dredge (TSHD): A self-propelled vessel that sucks dredged material through a draghead attached to a trailing pipe and stores it in a hopper.

- Cutter Suction Dredge (CSD): Uses a cutter head to loosen and break up hard materials, and a suction pump to remove the slurry.

- Bucket Wheel Dredge (BWD): Employs a large rotating wheel with buckets to excavate material and transport it to a conveyor belt.

- Grab Dredge: Uses a mechanical grab to excavate the material and lift it to the surface.

- Dustpan Dredge: A small vessel with a wide, flat blade that scoops up sediment from the bottom.

2. Describe the major components of a dredge and their functions?

Hydraulic System:

- Provides power for the pumps that create suction and discharge dredged material.

- Includes pumps, piping, valves, and control systems.

Mechanical System:

- Responsible for operating the cutter head, grab, or other excavation mechanisms.

- Includes engines, generators, gearboxes, and various machinery.

Electrical System:

- Provides power and control to all electrical components, such as lights, navigation systems, and communication equipment.

- Includes switchboards, transformers, and wiring.

Navigation System:

- Allows the dredge to accurately position itself and track its location.

- Includes GPS, radar, and other navigational aids.

3. Explain the process of dredging and the factors that affect it?

Process of Dredging:

- The dredge positions itself at the dredging site.

- The excavation mechanism (e.g., cutter head, grab) is deployed to loosen and remove material.

- The dredged material is pumped through a suction pipe and discharged into the hopper or onto a conveyor belt.

- Once the hopper is full or the desired depth is reached, the dredge transports the dredged material to a disposal site.

Factors Affecting Dredging:

- Type of material being dredged

- Depth and extent of the dredging area

- Environmental conditions (e.g., tides, currents)

- Availability of disposal sites

- Equipment used and its efficiency

4. Describe the maintenance procedures for hydraulic systems on dredges?

- Regular Inspections: Visually inspect for leaks, corrosion, and damage.

- Oil Changes: Replace hydraulic oil at specified intervals to maintain viscosity and prevent contamination.

- Filter Cleaning: Clean or replace filters to remove contaminants and protect components.

- Pressure Testing: Test system pressure to identify any leaks or blockages.

- Overhaul: Periodically disassemble and inspect major components, replace worn parts, and reassemble with new seals and gaskets.

5. Explain the safety precautions that must be followed when working on dredges?

- Personal Protective Equipment (PPE): Wear appropriate PPE such as hard hats, safety glasses, gloves, and life jackets.

- Confined Space Entry: Follow proper procedures for entering and working in confined spaces.

- Electrical Safety: Understand electrical hazards and lockout/tagout procedures.

- Working with Heavy Machinery: Be aware of moving parts and operate equipment safely.

- Water Safety: Take precautions to prevent slips, falls, and drowning.

- Environmental Hazards: Be aware of potential environmental hazards such as contaminated water or sediment.

6. Describe the troubleshooting process for a dredge that is not operating properly?

- Identify Symptoms: Observe and record the symptoms of the malfunction.

- Check Simple Issues: Verify fuel levels, electrical connections, and hydraulic fluid levels.

- Consult Manuals: Refer to manufacturers’ manuals for troubleshooting guidelines.

- Isolate the Issue: Narrow down the possible cause by testing different components.

- Repair or Replace: Identify the faulty component and repair or replace it accordingly.

- Test and Verify: Once repaired, test the system to ensure proper operation.

7. Explain the importance of proper lubrication for dredge components?

- Reduces Friction and Wear: Lubrication creates a barrier between moving parts, reducing friction and minimizing wear.

- Prevents Corrosion: Lubricants can form a protective film that prevents moisture and contaminants from reaching metal surfaces.

- Dissipates Heat: Lubricants help transfer heat away from critical components, preventing overheating.

- Improves Efficiency: Well-lubricated components operate more smoothly and efficiently, reducing energy consumption.

- Extends Component Lifespan: Proper lubrication can significantly extend the lifespan of dredge components by reducing wear and tear.

8. Describe the different types of materials that can be dredged?

- Soft Materials: Silt, clay, and sand

- Hard Materials: Rock, gravel, and hard-packed sediment

- Contaminated Materials: Sediment containing pollutants, such as heavy metals or chemicals

- Marine Plants: Seagrass, seaweed, and other aquatic vegetation

- Wildlife: Dredging can impact fish, shellfish, and other marine organisms

9. Explain the environmental regulations that apply to dredging operations?

- Clean Water Act: Regulates the discharge of dredged material into U.S. waters.

- Endangered Species Act: Protects threatened and endangered species and their habitats.

- National Environmental Policy Act (NEPA): Requires environmental impact assessments for major dredging projects.

- Coastal Zone Management Act: Protects and manages coastal resources.

- Local Regulations: Many states and municipalities have their own regulations governing dredging activities.

10. Describe your experience with dredge maintenance and repair?

During my previous role as a Dredge Mechanic at [Company Name], I was responsible for maintaining and repairing a fleet of dredges. My responsibilities included:

- Conducting routine inspections and preventive maintenance tasks

- Troubleshooting and repairing hydraulic, mechanical, and electrical systems

- Overhauling major components, such as engines, pumps, and gearboxes

- Fabricating and installing custom parts

- Ensuring that dredges were operating safely and efficiently

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dredge Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dredge Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dredge mechanics are responsible for the maintenance and repair of dredging equipment, including pumps, pipelines, and other components. They also work with engineers to design and implement new systems, and they may train other employees on how to operate and maintain the equipment.

1. Maintain and Repair Dredging Equipment

Dredge mechanics are responsible for maintaining and repairing all aspects of dredging equipment, including:

- Pumps

- Pipelines

- Engines

- Hydraulic systems

- Electrical systems

2. Design and Implement New Systems

Dredge mechanics work with engineers to design and implement new systems to improve the efficiency and productivity of dredging operations. This may involve:

- Developing new ways to control the flow of water and sediment

- Improving the efficiency of pumps and other equipment

- Designing new safety systems

3. Train Employees

Dredge mechanics may also train other employees on how to operate and maintain the equipment. This includes:

- Teaching employees how to identify and troubleshoot problems

- Providing instruction on how to perform routine maintenance tasks

- Ensuring that employees are up-to-date on the latest safety regulations

4. Other Responsibilities

Dredge mechanics may also be responsible for:

- Keeping records of all maintenance and repairs

- Ordering parts and supplies

- Supervising other employees

Interview Tips

Here are some tips to help you ace your interview for a dredge mechanic position:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

2. Prepare Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Highlight Your Experience and Skills

Make sure to highlight your experience and skills that are relevant to the dredge mechanic position. This may include experience in maintaining and repairing heavy equipment, or experience in designing and implementing new systems. You should also highlight any certifications or training that you have that would make you a valuable asset to the company.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and positive about the position. Show the interviewer that you are excited about the opportunity to work for the company and that you are confident in your abilities.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer any questions that you have about the position or the company. This shows that you are interested in the position and that you are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dredge Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.