Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Drier and Pulverizer Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

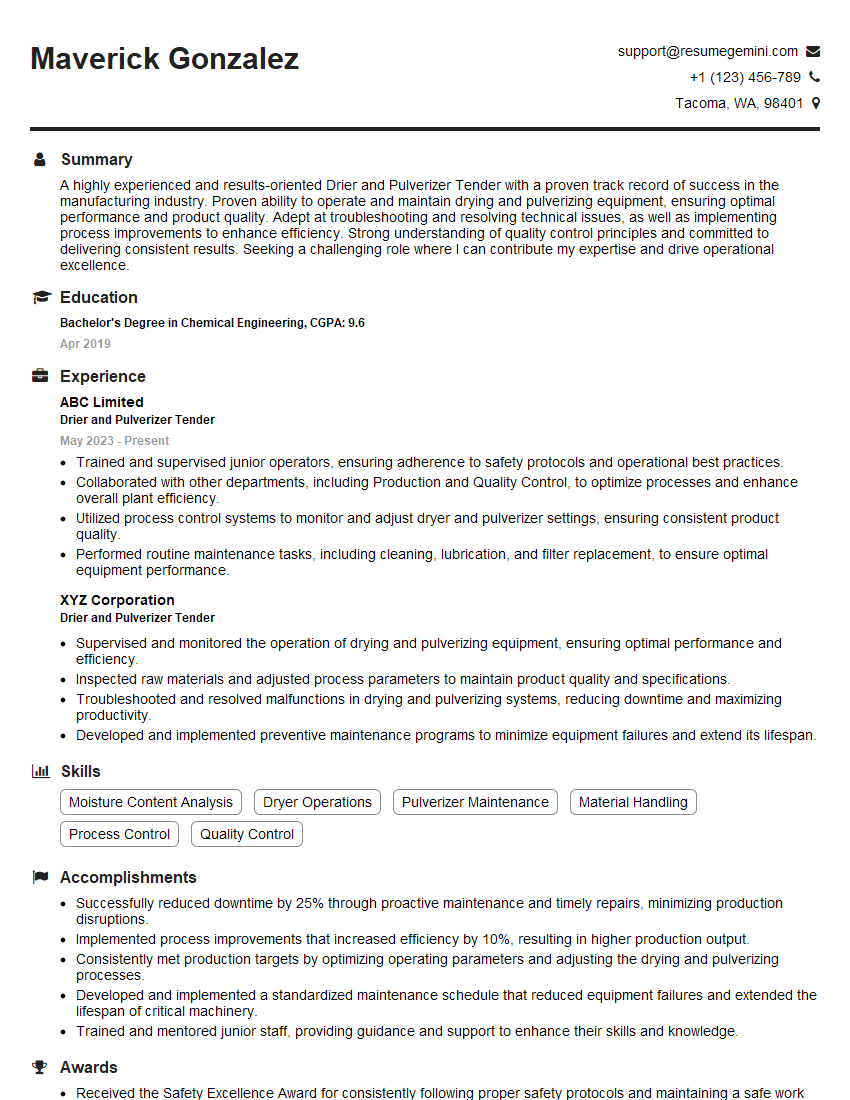

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drier and Pulverizer Tender

1. Explain the primary responsibilities of a Drier and Pulverizer Tender?

The primary responsibilities of a Drier and Pulverizer Tender typically include the following:

- Operating and monitoring driers and pulverizers to process and prepare raw materials.

- Ensuring proper functioning of equipment by performing regular maintenance and repairs.

- Monitoring the quality of dried and pulverized materials to meet specifications.

- Maintaining a safe and clean work environment by adhering to safety regulations.

- Collaborating with other plant personnel to ensure smooth operations.

2. Describe the different types of driers and pulverizers used in the industry?

Rotary Dryers

- Consist of a rotating cylinder that dries materials through heat and agitation.

- Used for drying various materials such as coal, minerals, and food products.

Spray Dryers

- Convert liquid materials into dry powder by atomizing the liquid and exposing it to hot air.

- Used in the production of pharmaceuticals, food additives, and detergents.

Hammer Mills

- Crush and pulverize materials using rapidly rotating hammers.

- Used for processing grains, minerals, and chemicals.

Ball Mills

- Grind and pulverize materials using tumbling balls within a rotating cylinder.

- Used for processing ores, minerals, and pigments.

3. What are the key parameters to monitor and control when operating a drier or pulverizer?

When operating a drier or pulverizer, the key parameters to monitor and control include:

- Temperature: Regulating the temperature ensures proper drying or pulverizing without damaging the material.

- Feed rate: Controlling the rate at which material is fed into the equipment optimizes efficiency and prevents overloading.

- Moisture content: Monitoring the moisture content of the dried material ensures it meets specifications.

- Particle size: Controlling the particle size of the pulverized material is crucial for its intended use.

- Airflow: Proper airflow is essential for effective drying and prevents clogging.

4. Explain the importance of preventive maintenance for driers and pulverizers?

Preventive maintenance is crucial for driers and pulverizers because it helps to:

- Extend the lifespan of the equipment by reducing wear and tear.

- Prevent breakdowns and unplanned downtime, ensuring uninterrupted operations.

- Improve safety by eliminating potential hazards caused by faulty equipment.

- Maintain optimal performance and efficiency, leading to increased productivity.

- Reduce maintenance costs in the long run by proactively addressing potential issues.

5. Describe the safety precautions that should be taken when operating driers and pulverizers?

When operating driers and pulverizers, the following safety precautions should be taken:

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Ensure proper guarding and interlocks are in place to prevent access to hazardous areas.

- Follow lockout/tagout procedures before performing maintenance or repairs.

- Be aware of potential hazards such as hot surfaces, rotating parts, and dust.

- Receive proper training and authorization before operating the equipment.

6. Explain how you would troubleshoot a drier that is not producing the desired moisture content?

To troubleshoot a drier that is not producing the desired moisture content, I would follow these steps:

- Check the temperature settings and adjust if necessary.

- Inspect the airflow and ensure it is adequate.

- Examine the feed rate and make adjustments to optimize drying.

- Verify the moisture sensor is functioning correctly.

- Inspect the material for any unusual properties that may affect drying.

7. Describe how you would calibrate a pulverizer to achieve a specific particle size?

To calibrate a pulverizer to achieve a specific particle size, I would follow these steps:

- Select the appropriate screen or grinding media for the desired particle size.

- Adjust the speed and feed rate of the pulverizer.

- Perform test runs and analyze the particle size distribution using a particle size analyzer.

- Make necessary adjustments to the settings until the desired particle size is achieved.

- Document the calibration settings for future reference.

8. Explain how you would handle a situation where a drier or pulverizer breaks down during operation?

If a drier or pulverizer breaks down during operation, I would take the following steps:

- Immediately shut down the equipment and isolate it from power.

- Inform the supervisor and relevant personnel.

- Assess the situation and identify the potential cause of the breakdown.

- If possible, attempt to make basic repairs or adjustments to restore operation.

- If major repairs are required, arrange for qualified maintenance personnel to address the issue.

9. Describe your experience with optimizing the efficiency of driers and pulverizers?

In my previous role, I implemented several measures to optimize the efficiency of driers and pulverizers, including:

- Conducted energy audits to identify areas of energy waste.

- Installed energy-efficient motors and variable frequency drives.

- Optimized the drying and pulverizing processes to reduce energy consumption.

- Improved maintenance practices to extend equipment lifespan and reduce downtime.

- Trained operators on best practices for efficient operation.

10. Explain how you would contribute to the team as a Drier and Pulverizer Tender?

As a Drier and Pulverizer Tender, I would contribute to the team by:

- Leveraging my expertise to ensure the efficient operation of driers and pulverizers.

- Actively participating in preventive maintenance and troubleshooting procedures.

- Collaborating with other team members to maintain a safe and productive work environment.

- Sharing my knowledge and experience with colleagues to enhance team performance.

- Continuously seeking opportunities to improve processes and optimize operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drier and Pulverizer Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drier and Pulverizer Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drier and Pulverizer Tenders are responsible for the operation and maintenance of driers and pulverizers in a variety of industrial settings. They ensure that these machines are operating efficiently and safely, and that the materials being processed meet the required specifications.

1. Operate and Monitor Driers and Pulverizers

Drier and Pulverizer Tenders are responsible for operating and monitoring driers and pulverizers. They set up and adjust the machines according to the required specifications, and monitor the temperature, pressure, and other operating parameters to ensure that the machines are operating efficiently and safely.

- Operate driers and pulverizers to dry and grind materials.

- Monitor operating parameters, such as temperature, pressure, and flow rate, to ensure that the machines are operating efficiently and safely.

2. Maintain Driers and Pulverizers

Drier and Pulverizer Tenders are also responsible for maintaining driers and pulverizers. They perform routine maintenance tasks, such as cleaning, lubricating, and inspecting the machines. They also troubleshoot and repair minor problems, and refer major problems to qualified technicians.

- Perform routine maintenance tasks, such as cleaning, lubricating, and inspecting the machines.

- Troubleshoot and repair minor problems.

3. Ensure Product Quality

Drier and Pulverizer Tenders are responsible for ensuring that the materials being processed meet the required specifications. They take samples of the materials and test them to ensure that they meet the required quality standards.

- Take samples of the materials being processed and test them to ensure that they meet the required quality standards.

- Make adjustments to the operating parameters of the driers and pulverizers to ensure that the materials meet the required specifications.

4. Work Safely

Drier and Pulverizer Tenders work in a variety of industrial settings, and they must be aware of the potential hazards associated with their work. They must follow all safety procedures and wear the appropriate personal protective equipment.

- Follow all safety procedures.

- Wear the appropriate personal protective equipment.

Interview Tips

In order to ace an interview for a Drier and Pulverizer Tender position, it is important to be prepared and to have a good understanding of the job responsibilities. The following are some tips to help you prepare for your interview:

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website.

- Read articles about the company and the industry.

- Talk to people who work for the company.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you may be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions ahead of time so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer interview questions.

- Be specific and provide examples.

- Practice your answers with a friend or family member.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience and qualifications. Be prepared to talk about your work history, your skills, and your education.

- Highlight your experience operating and maintaining driers and pulverizers.

- Discuss your troubleshooting and repair skills.

- Explain your understanding of the quality control process.

4. Be Enthusiastic and Professional

First impressions matter, so it is important to be enthusiastic and professional during your interview. Dress appropriately, arrive on time, and be prepared to answer questions thoughtfully and respectfully.

- Be confident and enthusiastic.

- Dress appropriately.

- Arrive on time for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drier and Pulverizer Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.