Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Drier Operator Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Drier Operator Helper so you can tailor your answers to impress potential employers.

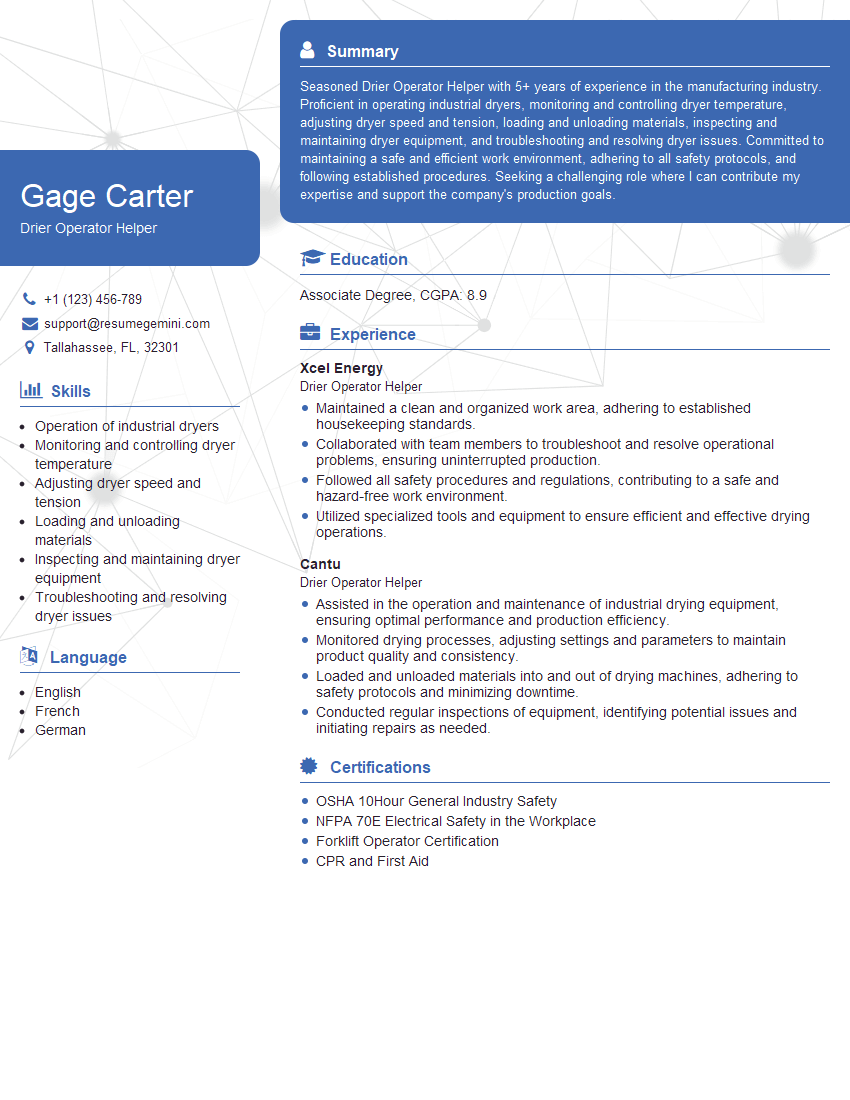

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drier Operator Helper

1. How do you inspect and clean the equipment used in the drying process, such as screens, feed chutes, and cyclones?

To ensure efficient drying operation, I adhere to a comprehensive cleaning and inspection routine for all equipment involved in the process. Here’s how I approach these tasks:

- Screens: I regularly inspect screens for any damage or blockages. I clean them using compressed air or brushes to remove any accumulated material that could affect airflow.

- Feed Chutes: I check feed chutes for any blockages or wear and tear. I remove any obstructions manually and inspect for any damage that may require repairs.

- Cyclones: I inspect cyclones for any build-up of dust or material. I follow manufacturer guidelines for cleaning cyclones using compressed air or water to maintain optimal performance.

2. Can you explain the process of monitoring and adjusting dryer temperature and airflow to ensure proper drying conditions?

Monitoring and adjusting dryer temperature and airflow are crucial for achieving the desired drying results. Here’s how I manage these parameters:

- Temperature Monitoring: I use temperature sensors to monitor the temperature within the dryer. I compare the actual temperature to the desired temperature and make necessary adjustments to the heat source.

- Airflow Monitoring: I use airflow meters to monitor the airflow through the dryer. I adjust the airflow rate by controlling fans or dampers to ensure optimal drying conditions.

- Adjustments: Based on the monitoring data, I adjust the heat source and airflow rate to maintain the desired drying conditions. I fine-tune these settings to achieve the required moisture content and product quality.

3. How do you troubleshoot common problems that may arise during the drying process, such as uneven drying, over-drying, or equipment malfunctions?

Troubleshooting common drying problems is an essential part of my responsibilities as a Drier Operator Helper. I follow a systematic approach to identify and resolve issues efficiently:

- Uneven Drying: I check for blockages in the feed chutes or screens. I also inspect the airflow distribution within the dryer to ensure uniform drying.

- Over-Drying: I monitor the temperature and airflow settings. If the temperature is too high or the airflow is too low, I adjust them accordingly to prevent over-drying.

- Equipment Malfunctions: I inspect the equipment for any visible damage or loose connections. I follow manufacturer guidelines for troubleshooting and repair procedures to restore the equipment to working order.

4. Describe your experience in maintaining the cleanliness and organization of the work area, including proper storage of materials and waste disposal.

Maintaining a clean and organized work area is essential for safety and efficiency. Here’s how I ensure a tidy and well-managed work environment:

- Equipment Cleanliness: I regularly clean and disinfect all equipment, including screens, feed chutes, and cyclones, to prevent contamination and ensure optimal performance.

- Material Storage: I follow designated storage procedures to keep materials organized and accessible. I store materials in dry and ventilated areas to prevent spoilage or damage.

- Waste Disposal: I adhere to established waste disposal protocols to dispose of waste materials safely and responsibly. I segregate waste into appropriate containers and follow proper disposal procedures.

5. Discuss your ability to work effectively in a team environment, collaborating with other operators and maintenance personnel to achieve production goals.

Collaboration and teamwork are vital in the drying process. Here’s how I contribute to a productive and cohesive team environment:

- Communication: I actively communicate with team members to share information, coordinate tasks, and resolve issues effectively.

- Support: I provide support to other operators when needed, assisting with equipment maintenance, troubleshooting, and ensuring smooth production flow.

- Problem-Solving: I collaborate with maintenance personnel to identify and resolve equipment issues promptly, minimizing downtime and maintaining productivity.

6. Describe your experience in working with different types of drying equipment, such as rotary dryers, flash dryers, and spray dryers.

My experience encompasses working with various types of drying equipment, including:

- Rotary Dryers: I have operated rotary dryers used for drying granular materials. I am familiar with their operation, maintenance, and troubleshooting procedures.

- Flash Dryers: I have assisted in operating flash dryers, which are used for drying fine powders. I understand their high-temperature and short-residence-time operation.

- Spray Dryers: I have worked with spray dryers used for drying liquid materials. I am aware of their atomization and drying processes, as well as their cleaning and maintenance requirements.

7. How do you ensure the quality of the dried product meets specifications and customer requirements?

Ensuring product quality is paramount. Here’s how I contribute to maintaining high standards:

- Monitoring: I routinely monitor the drying process parameters, such as temperature, airflow, and moisture content, to ensure they meet the desired specifications.

- Sampling and Testing: I collect product samples and conduct quality tests to verify the product meets the required moisture content, particle size, and other specifications.

- Corrective Actions: Based on the test results, I work with the team to identify any deviations and implement corrective actions to maintain product quality.

8. Explain your understanding of safety protocols and regulations related to the drying process, including proper handling of hazardous materials.

Safety is a top priority in the drying process. I am well-versed in the following safety protocols and regulations:

- Hazard Identification: I am aware of the potential hazards associated with drying operations, such as dust explosions, fire, and chemical spills.

- Personal Protective Equipment (PPE): I adhere to PPE requirements, including wearing appropriate clothing, gloves, eye protection, and respiratory protection when necessary.

- Safe Handling of Hazardous Materials: I am trained in handling hazardous materials, including proper storage, handling, and disposal procedures to minimize risks.

9. Describe a situation where you had to make a quick decision to address an unexpected issue during the drying process.

During a drying operation, I encountered an unexpected issue when a feed chute became blocked, causing material buildup and potentially affecting product quality. Here’s how I responded:

- Assessment: I quickly assessed the situation and identified the blockage in the feed chute.

- Action: I immediately stopped the drying process and manually removed the blockage to clear the chute.

- Monitoring: I closely monitored the drying process after resuming operation to ensure the issue was resolved and product quality was not compromised.

10. How do you stay updated with the latest industry trends and best practices in drying technologies?

To keep my knowledge current, I actively engage in the following activities:

- Industry Publications: I read industry magazines and technical journals to stay informed about the latest drying technologies and best practices.

- Conferences and Seminars: I attend industry conferences and seminars to connect with experts and learn about emerging trends and advancements in drying.

- Online Resources: I utilize online platforms and resources to access technical articles, research papers, and industry news related to drying technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drier Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drier Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Drier Operator Helper assists the Drier Operator in the operation and maintenance of drying equipment, ensuring the efficient and safe production of dried products in various industries such as food processing, pharmaceuticals, and chemicals.

1. Equipment Operation and Maintenance

Under the guidance of the Drier Operator, the Helper performs routine inspections and maintenance of drying equipment, including conveyors, dryers, and exhaust systems.

- Monitors equipment performance, identifying and reporting any malfunctions or deviations from operating parameters.

- Cleans and lubricates equipment, ensures proper functioning, and extends equipment life.

2. Material Handling and Preparation

The Helper assists in the preparation and handling of materials to be dried.

- Loads and unloads materials into and out of dryers, adhering to safety protocols and quality standards.

- Prepares materials for drying, ensuring proper moisture content and particle size to optimize drying efficiency.

3. Process Control and Monitoring

The Helper assists in monitoring and controlling the drying process to achieve desired product quality and efficiency.

- Observes product characteristics, such as moisture content, color, and texture, and reports any variations to the Operator.

- Assists in adjusting process parameters, such as temperature, humidity, and airflow, based on product specifications and process requirements.

4. Safety and Housekeeping

The Helper prioritizes safety in all aspects of the role and actively maintains a clean and organized work environment.

- Follows established safety protocols, wears appropriate personal protective equipment, and reports any potential hazards.

- Maintains a clean work area, disposing of waste materials and spills promptly to prevent contamination and accidents.

Interview Tips

Preparing thoroughly for your Drier Operator Helper interview can significantly increase your chances of success.

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and specific products or services related to drying operations.

- Review the job description carefully, highlighting your skills and experiences that align with the required responsibilities.

- Identify any unique aspects of the role or industry that you can address during the interview to demonstrate your knowledge and interest.

2. Practice Common Interview Questions

Prepare answers to common interview questions that assess your technical abilities, attention to detail, and safety awareness.

- Describe your experience in operating or assisting with drying equipment, including specific types of dryers and materials handled.

- Provide examples of how you ensure product quality and efficiency during the drying process.

- Explain how you prioritize safety in your work and describe your understanding of safety protocols in a drying environment.

3. Highlight Transferable Skills

Emphasize transferable skills that are valuable in a Drier Operator Helper role, even if you don’t have direct experience in the drying industry.

- Showcase your mechanical aptitude, ability to troubleshoot equipment issues, and willingness to learn new technologies.

- Demonstrate your attention to detail, ability to follow instructions, and commitment to maintaining a clean and organized work environment.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role and company.

- Inquire about the company’s growth plans and how the Drier Operator Helper position contributes to those goals.

- Ask about opportunities for professional development and training within the organization.

- Seek clarification on any aspects of the role or company culture that are not fully understood.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive for your interview on time. This demonstrates respect for the interviewer and the company.

- Choose attire that is clean, pressed, and appropriate for a manufacturing or industrial setting.

- Plan your route and allow ample time to arrive at the interview location to avoid any delays.

6. Be Enthusiastic and Confident

A positive attitude and confidence can make a significant difference in your interview. Show enthusiasm for the role and the company, and convey your belief in your abilities to contribute to their success.

- Maintain eye contact, speak clearly and confidently, and use positive body language.

- Highlight your passion for the industry and your eagerness to learn and grow in the Drier Operator Helper role.

Next Step:

Now that you’re armed with the knowledge of Drier Operator Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Drier Operator Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini