Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Drier Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

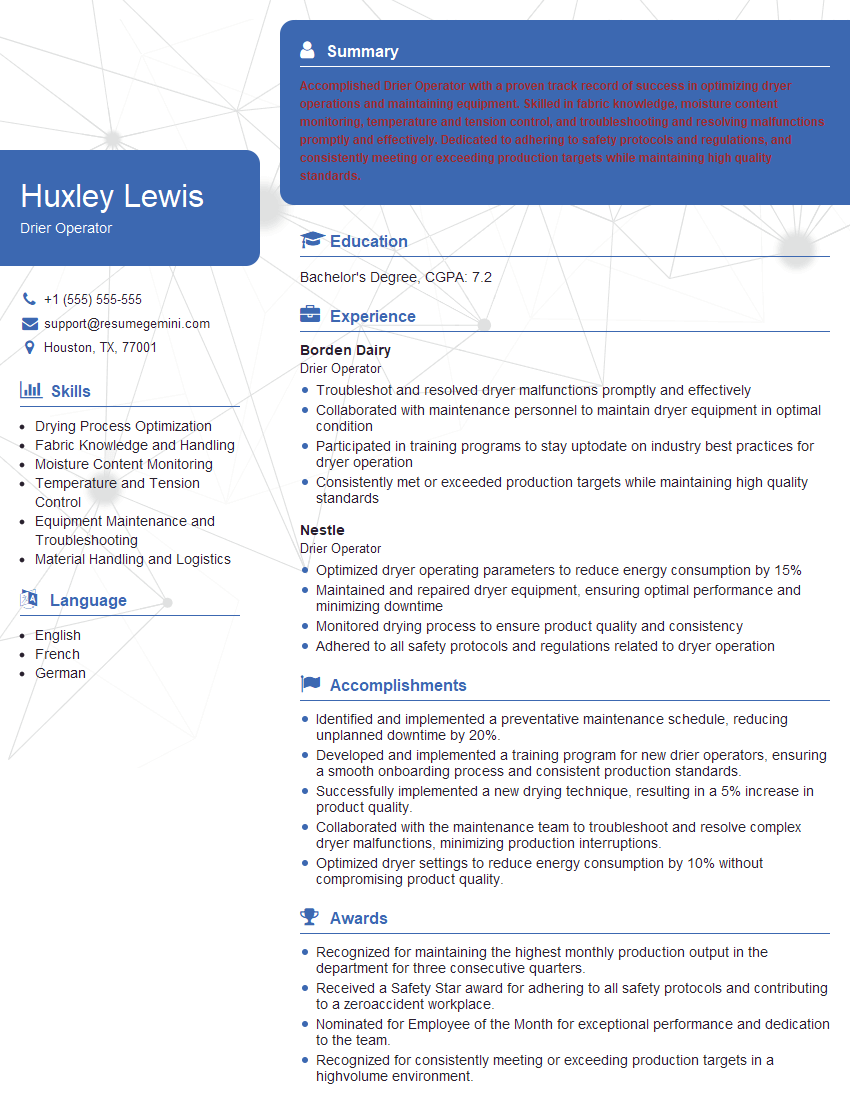

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drier Operator

1. Explain the role and responsibilities of a Drier Operator.

A Drier Operator plays a crucial role in ensuring the efficient and safe operation of a drier in industrial settings. Their primary responsibilities include:

- Monitoring and controlling the drying process to meet specified moisture content and quality standards.

- Performing regular maintenance and inspections on the drier and its components.

- Troubleshooting and resolving any operational issues that may arise during the drying process.

- Ensuring that safety protocols are followed, including proper use of personal protective equipment.

- Collaborating with other operators and supervisors to maintain a productive and efficient work environment.

2. Describe the different types of driers you have operated and their specific mechanisms.

Rotary Dryer

- Used for drying materials like wood chips, chemicals, and agricultural products.

- Material is fed into the rotating cylinder, where it is lifted and dropped, exposing it to hot air.

Flash Dryer

- Suitable for drying fine powders and granules.

- Material is suspended in a hot gas stream and rapidly dried.

Spray Dryer

- Used to produce dry powders from liquid feeds.

- Liquid is atomized into small droplets and sprayed into a hot gas stream, resulting in rapid drying.

3. What are the critical control points you monitor to ensure optimal drying performance?

To maintain optimal drying performance, I closely monitor several critical control points, including:

- Temperature: Maintaining the appropriate temperature within the drier is vital for achieving the desired moisture content.

- Airflow: Adequate airflow ensures uniform drying and prevents overheating.

- Material feed rate: Controlling the rate at which material is fed into the drier is crucial for efficient operation.

- Residence time: Monitoring the time material spends within the drier allows me to adjust settings for optimal drying.

- Product quality: Regularly sampling and testing the dried material ensures it meets the required specifications.

4. How do you handle troubleshooting and resolve common problems associated with drier operations?

Troubleshooting and resolving common drier problems is a key aspect of my role. I follow a systematic approach to identify and address issues:

- Identify and analyze symptoms: I carefully observe the drier’s performance and identify any deviations from normal operation.

- Consult technical documentation: I refer to manuals and specifications to understand the potential causes of the problem.

- Perform inspections and tests: I conduct thorough inspections and run diagnostic tests to pinpoint the root cause.

- Implement corrective actions: Based on the diagnosis, I implement appropriate corrective measures, such as adjusting settings, performing maintenance, or replacing components.

- Monitor and evaluate: After implementing solutions, I closely monitor the drier’s performance to ensure the issue has been resolved effectively.

5. Explain the safety protocols and emergency procedures you are familiar with in a drier operation setting.

Safety is paramount in any drier operation. I am well-versed in the following protocols and emergency procedures:

- Proper use of personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

- Identifying and avoiding potential hazards, such as moving machinery and hot surfaces.

- Following proper lockout/tagout procedures when performing maintenance or repairs.

- Understanding and complying with all applicable safety regulations and standards.

- Responding appropriately to emergencies, such as fires, explosions, or equipment malfunctions.

6. How do you stay updated on advancements in drying technology and best practices?

To stay abreast of the latest advancements and best practices in drying technology, I actively engage in the following:

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in online forums and discussions.

- Collaborating with colleagues and industry experts.

- Seeking out training opportunities to enhance my skills.

7. Describe a situation where you successfully resolved a complex drying issue that impacted production.

In a previous role, I encountered a complex drying issue that was affecting production efficiency. The drier was not achieving the desired moisture content, resulting in product rejections. I took the following steps to resolve the problem:

- Thoroughly analyzed the drier’s performance data and identified anomalies.

- Inspected the equipment and identified a malfunctioning temperature sensor.

- Replaced the faulty sensor and recalibrated the temperature control system.

- Optimized the airflow and material feed rate based on the manufacturer’s specifications.

- Monitored the drying process closely and made necessary adjustments to ensure consistent product quality.

8. How do you prioritize tasks and manage multiple responsibilities in a fast-paced drier operation environment?

In a fast-paced drier operation environment, I prioritize tasks and manage multiple responsibilities effectively through the following strategies:

- Utilizing a task management system to track assignments and deadlines.

- Prioritizing tasks based on urgency, importance, and impact on production.

- Delegating responsibilities to team members when appropriate.

- Communicating effectively with colleagues and supervisors to ensure smooth coordination.

- Maintaining a proactive approach to anticipate potential issues and plan accordingly.

9. Explain the importance of maintaining accurate records and documentation in a drier operation setting.

Maintaining accurate records and documentation in a drier operation setting is crucial for several reasons:

- Compliance with regulatory and industry standards.

- Tracking production data for performance analysis and optimization.

- Providing evidence of proper maintenance and troubleshooting.

- Facilitating knowledge transfer and training of new operators.

- Creating a historical record for future reference and troubleshooting.

10. How do you contribute to a positive and productive work environment within a drier operation team?

I believe in fostering a positive and productive work environment by actively contributing in the following ways:

- Collaborating effectively with team members and supervisors.

- Sharing knowledge and expertise with colleagues.

- Providing support and assistance when needed.

- Maintaining a positive attitude and demonstrating enthusiasm for my work.

- Participating in team discussions and offering suggestions for improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Drier Operator plays an essential role in ensuring the efficient and safe operation of drying equipment in various industrial settings. Their responsibilities encompass a wide range of tasks, including:

1. Monitoring and Controlling Drying Processes

Drier Operators meticulously monitor the drying equipment, ensuring that the temperature, humidity, and other process parameters are within the specified ranges. They make necessary adjustments to optimize drying efficiency and prevent product damage.

- Monitor temperature, humidity, and airflow to maintain optimal drying conditions.

- Adjust process parameters to ensure efficient drying and prevent over- or under-drying.

2. Loading and Unloading Materials

They are responsible for loading and unloading materials into and from the drying equipment. They ensure proper handling of materials to prevent contamination and avoid equipment damage.

- Load and unload materials (e.g., textiles, chemicals, food products) into and from drying equipment.

- Follow safety protocols and use proper handling techniques to prevent spills, accidents, and product damage.

3. Maintaining Equipment

Drier Operators conduct regular inspections and maintenance tasks to ensure the smooth operation and longevity of drying equipment. They follow manufacturer guidelines and safety regulations to keep the equipment in optimal condition.

- Perform routine inspections to identify and address potential issues.

- Conduct regular maintenance tasks (e.g., cleaning, lubrication, filter replacement) to prevent breakdowns and ensure equipment reliability.

4. Troubleshooting and Problem-Solving

When issues arise, Drier Operators diagnose and troubleshoot problems promptly to minimize production downtime. They analyze equipment performance, identify root causes, and implement effective solutions.

- Diagnose and troubleshoot equipment malfunctions, identifying and resolving issues efficiently.

- Implement corrective actions to restore equipment operation and minimize production disruptions.

Interview Tips

Preparing for an interview for a Drier Operator position requires thorough research and a well-structured approach. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s profile, industry, and the specific requirements of the Drier Operator role. Understand the company’s culture, values, and the challenges and opportunities associated with the position.

- Visit the company’s website and social media pages for information about their business, products, and services.

- Read industry-related articles and news to gain insights into the latest trends and challenges in the field.

- Review the job description thoroughly, highlighting key responsibilities and qualifications.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview responses to showcase your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

- Emphasize your experience in operating and maintaining drying equipment, highlighting your understanding of drying processes and equipment.

- Demonstrate your problem-solving habilidades by providing examples of how you identified and resolved equipment issues.

- Showcase your attention to detail and commitment to safety by explaining your practices for monitoring process parameters and adhering to safety protocols.

3. Practice Common Interview Questions

Prepare for common interview questions by researching typical questions asked in Drier Operator interviews. Practice answering these questions out loud or with a mock interview partner.

- Describe your experience in operating and maintaining drying equipment.

- How do you ensure the efficient and safe operation of drying processes?

- Give an example of a time you solved a complex problem with drying equipment.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare questions that show you have researched the company and the role and that you are enthusiastic about the opportunity.

- Inquire about the company’s goals and challenges in the industry.

- Ask about opportunities for professional development and growth within the company.

- Request specific details about the day-to-day responsibilities of the Drier Operator position.

Next Step:

Now that you’re armed with the knowledge of Drier Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Drier Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini