Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Drill Press Operator for Metal interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Drill Press Operator for Metal so you can tailor your answers to impress potential employers.

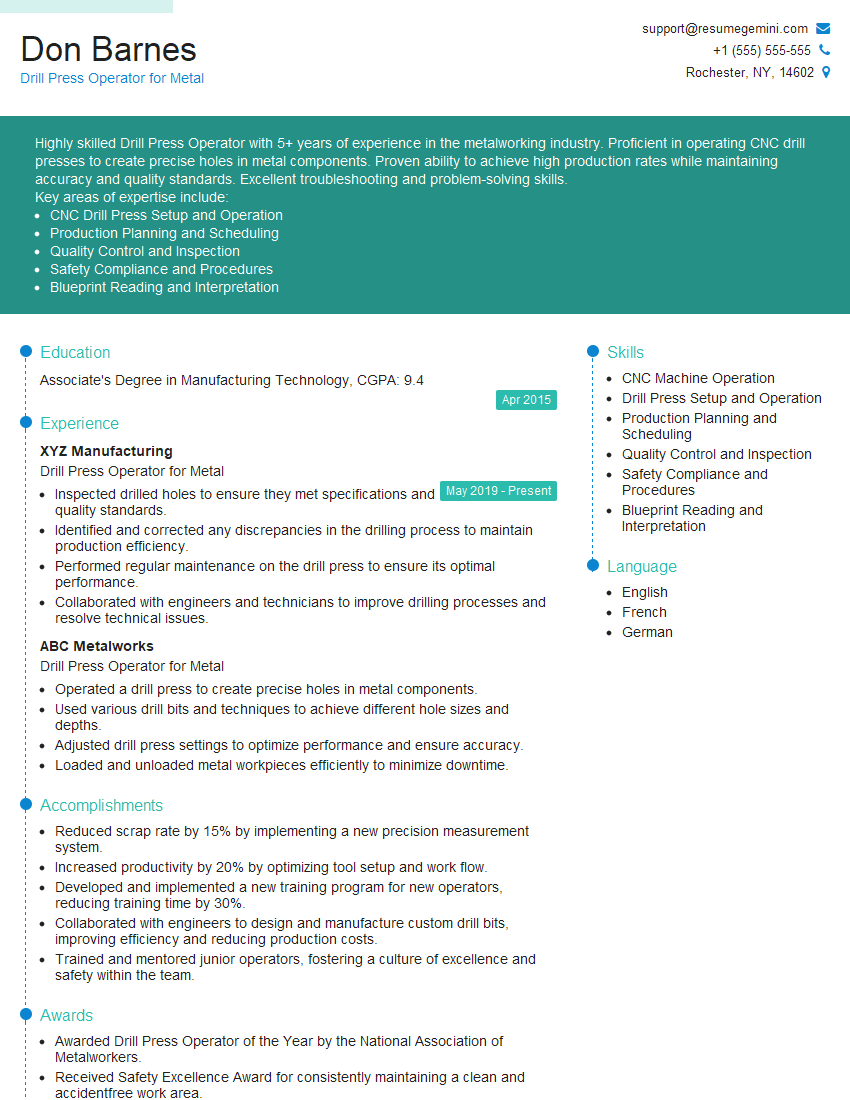

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drill Press Operator for Metal

1. What are the different types of drill presses and what are their advantages and disadvantages?

- Benchtop drill presses: These are small and compact, and are ideal for light-duty drilling tasks in a workshop or garage.

- Floor drill presses: These are larger and more powerful, and are used for heavy-duty drilling tasks in industrial settings.

- Radial drill presses: These have a radial arm that allows for drilling holes at different angles and locations.

- Magnetic drill presses: These are portable and can be used to drill holes in metal surfaces without the need for a drill stand.

2. What are the different types of drill bits and when should they be used?

- Twist drills: These are the most common type of drill bit, and are used for general-purpose drilling.

- Auger bits: These are used for drilling large holes, and have a spiral flute that helps to remove chips.

- Brad point bits: These have a pointed tip that helps to center the bit, and are used for drilling small holes in wood.

- Forstner bits: These have a flat bottom and are used for drilling flat-bottomed holes.

3. What are the different speeds and feeds that can be used on a drill press?

- Speed: This is measured in revolutions per minute (RPM), and it determines how fast the drill bit will rotate.

- Feed: This is measured in inches per minute (IPM), and it determines how fast the drill bit will feed into the workpiece.

- The correct speed and feed will depend on the type of material being drilled, the size of the hole being drilled, and the drill bit being used.

4. What are the safety precautions that should be taken when operating a drill press?

- Always wear safety glasses and ear protection.

- Secure the workpiece properly in a vise or clamp.

- Use the correct speed and feed for the material being drilled.

- Never reach into the drill press while it is running.

- Unplug the drill press before making any adjustments or repairs.

5. What are some common problems that can occur when drilling holes and how can they be prevented?

- Drill bit breakage: This can be prevented by using the correct speed and feed, and by ensuring that the drill bit is sharp.

- Workpiece damage: This can be prevented by securing the workpiece properly, and by using a drill press table to support the workpiece.

- Inaccurate holes: This can be prevented by using a drill guide or template, and by ensuring that the drill press is properly aligned.

6. What are some tips for drilling holes in metal?

- Use a sharp drill bit.

- Use the correct speed and feed.

- Use a lubricant to help reduce friction and prevent overheating.

- Drill a pilot hole before drilling the final hole.

- Deburr the hole after drilling to remove any sharp edges.

7. What are some tips for drilling holes in plastic?

- Use a sharp drill bit.

- Use a slow speed and feed to prevent the plastic from melting.

- Use a lubricant to help reduce friction and prevent overheating.

- Drill a pilot hole before drilling the final hole.

- Deburr the hole after drilling to remove any sharp edges.

8. What are some tips for drilling holes in wood?

- Use a sharp drill bit.

- Use the correct speed and feed for the type of wood being drilled.

- Drill a pilot hole before drilling the final hole.

- Countersink the hole to prevent the screw head from protruding.

- Deburr the hole after drilling to remove any sharp edges.

9. What are some of the different types of drill press attachments and how are they used?

- Drill press table: This is a flat surface that supports the workpiece and helps to keep it stable during drilling.

- Drill press vise: This is a clamping device that holds the workpiece securely in place.

- Drill press fence: This is a guide that helps to ensure that the holes are drilled in the correct location.

- Drill press quill stop: This is a stop that limits the travel of the drill bit, which is useful for drilling holes to a specific depth.

10. What are some of the common maintenance tasks that should be performed on a drill press?

- Cleaning the drill press table and vise.

- Lubricating the drill press spindle and bearings.

- Tightening the drill press belts.

- Inspecting the drill press electrical cord and plug.

- Having the drill press serviced by a qualified technician on a regular basis.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drill Press Operator for Metal.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drill Press Operator for Metal‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Drill Press Operator for Metal is a skilled professional who operates a drill press to create holes in metal workpieces. Some of the key job responsibilities include:

1. Preparing the Drill Press

The operator must prepare the drill press by selecting the correct drill bit, setting the speed and feed rates, and ensuring that the workpiece is securely clamped in place.

2. Operating the Drill Press

The operator must then operate the drill press to drill the holes in the workpiece. This involves carefully guiding the drill bit through the workpiece while maintaining the correct speed and feed rates.

3. Inspecting the Work

Once the holes have been drilled, the operator must inspect the work to ensure that the holes are the correct size and location. They must also check for any defects in the workpiece.

4. Maintaining the Drill Press

The operator is also responsible for maintaining the drill press. This includes cleaning and lubricating the drill press, and replacing the drill bits as needed.

Interview Tips

Before you go to your interview for a Drill Press Operator for Metal position, there are several things you can do to increase your chances of success:

1. Research the Company and the Position

Take some time to research the company you’re applying to and the position you’re interviewing for. This will help you understand the company’s culture and values, as well as the specific requirements of the position. This information will be helpful in answering the interviewer’s questions and demonstrating your interest in the position.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Dress Professionally

First impressions matter, so it’s important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

4. Be Punctual

Punctuality shows that you respect the interviewer’s time. Plan to arrive at the interview location a few minutes early so that you can relax and compose yourself before the interview begins.

5. Be Enthusiastic

Enthusiasm is contagious, and it can make a positive impression on the interviewer. Let the interviewer know that you’re excited about the position and the opportunity to work for the company. However, it is important to avoid coming off as overbearing or pushy.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Drill Press Operator for Metal role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.