Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Drill Press Operator Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

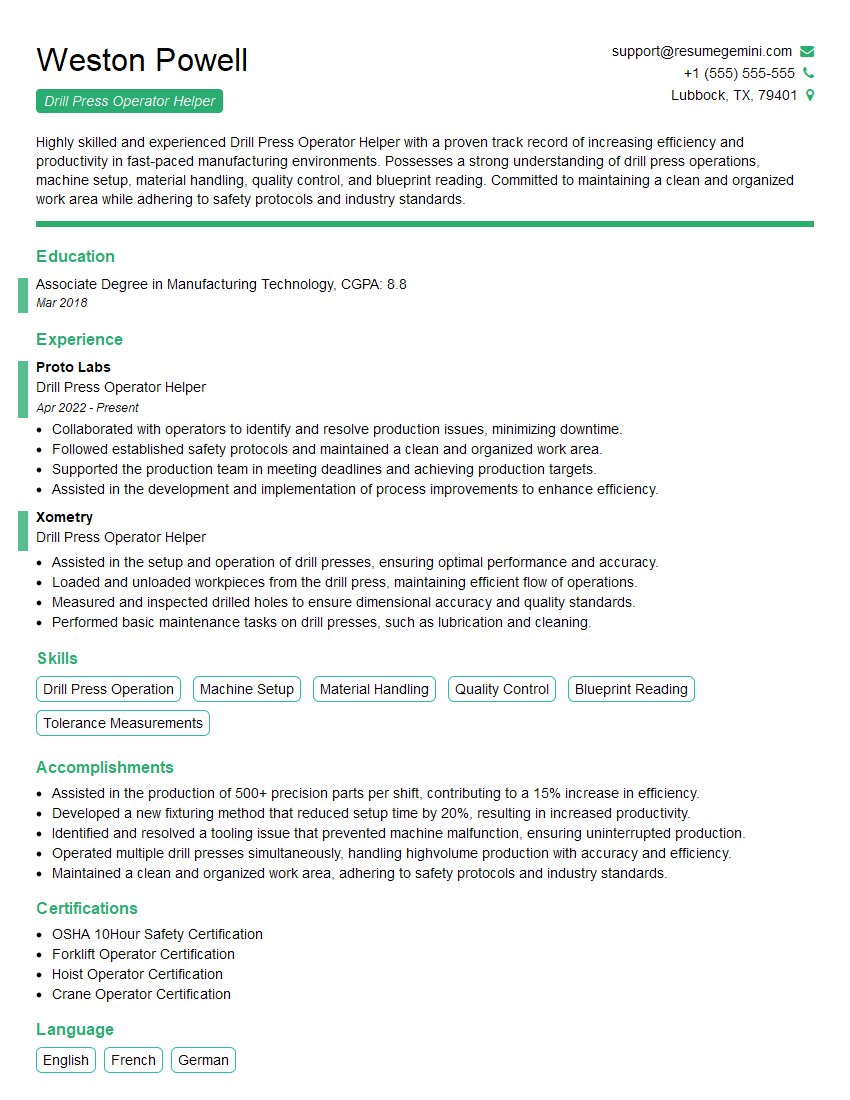

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drill Press Operator Helper

1. What are the different types of drill press machines?

There are various types of drill press machines, including:

- Benchtop drill press: Compact and suitable for small workshops or hobbyists.

- Floor drill press: Larger and more powerful, used for industrial applications.

- Radial drill press: Features a rotating arm that allows for drilling at different angles.

- Magnetic drill press: Mounts directly onto metal surfaces, ideal for drilling in hard-to-reach areas.

- CNC drill press: Computer-controlled for precise and automated drilling operations.

2. What are the key components of a drill press?

Drill bit

- The cutting tool that creates the hole in the workpiece.

Chuck

- Holds the drill bit securely in place.

Spindle

- Rotates the chuck and drill bit.

Table

- Supports and positions the workpiece.

Base

- Provides stability and support for the drill press.

3. What are the safety precautions to consider when operating a drill press?

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Secure the workpiece firmly to prevent it from moving during drilling.

- Use the proper drill bit for the material being drilled.

- Start the drill press before touching the drill bit to the workpiece.

- Never leave the drill press unattended while it is running.

- Maintain a clean work area and keep tools in good condition.

4. How do you align the drill press chuck with the workpiece?

To align the drill press chuck with the workpiece, you can use the following steps:

- Place the workpiece on the drill press table and secure it in place.

- Lower the spindle and chuck until the drill bit tip just touches the surface of the workpiece.

- While holding the drill bit in place, rotate the chuck by hand until the drill bit is perfectly centered over the desired drilling location.

- Tighten the chuck to secure the drill bit in the aligned position.

5. What is the purpose of coolant when drilling?

- Reduces friction and heat at the drill bit and workpiece interface.

- Lubricates the drill bit and extends its lifespan.

- Helps to remove chips and debris from the drilling area.

- Improves the surface finish of the drilled hole.

6. How do you determine the correct feed rate for drilling?

The feed rate for drilling depends on several factors, including:

- Drill bit diameter

- Material being drilled

- Depth of the hole

- Drill press speed

- Desired surface finish

Generally, you can use the following formula as a starting point:

Feed rate (in/min) = Drill bit diameter (in) x Drill press speed (rpm) / 100

7. What are the common problems that can occur during drilling and how can they be resolved?

Drill bit breakage

- Using a dull or damaged drill bit.

- Excessive feed rate.

- Misalignment between the drill bit and workpiece.

Workpiece deformation

- Improperly secured workpiece.

- Excessive drilling pressure.

- Using a drill bit that is too large for the material.

Poor surface finish

- Using a dull or damaged drill bit.

- Excessive feed rate.

- Lack of coolant or lubricant.

8. What is the difference between spot drilling and counterboring?

- Spot drilling: Creates a small, shallow hole to provide a starting point for a larger drill bit.

- Counterboring: Enlarges an existing hole to a larger diameter, typically to create a recess for a countersunk screw or bolt head.

9. How do you maintain a drill press to ensure optimal performance?

- Regularly clean and lubricate all moving parts.

- Inspect and sharpen drill bits as needed.

- Check the alignment of the chuck and spindle.

- Tighten any loose bolts or screws.

- Follow the manufacturer’s recommended maintenance schedule.

10. How do you measure the accuracy of a drilled hole?

- Use a micrometer or caliper to measure the hole diameter.

- Use a depth gauge to measure the hole depth.

- Use a dial indicator to check the hole for roundness and straightness.

- Compare the measured values to the specified tolerances.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drill Press Operator Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drill Press Operator Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Drill Press Operator Helper plays a crucial role in assisting the Drill Press Operator, ensuring the smooth operation of drilling processes. Key job responsibilities include:

1. Material Handling and Setup

Loading and unloading workpieces onto the drill press table

- Positioning and securing workpieces using fixtures and tools

- Checking workpiece measurements and ensuring proper alignment

2. Drill Operation Assistance

Assisting in setting up and operating the drill press

- Installing and removing drill bits and other cutting tools

- Adjusting drill speed, depth, and feed rate based on workpiece specifications

3. Quality Control and Inspection

Inspecting drilled holes and workpieces for accuracy and quality

- Checking hole dimensions, surface finish, and conformance to specifications

- Identifying defects and reporting them to the Drill Press Operator

4. Machine Maintenance and Cleaning

Maintaining and cleaning the drill press and work area

- Performing daily maintenance tasks, such as lubrication and cleaning

- Reporting any equipment issues or malfunctions promptly

Interview Tips

To ace the interview for a Drill Press Operator Helper position, it’s essential to prepare thoroughly and showcase your relevant skills and experience. Here are some tips and hacks:

1. Research the Company and Industry

Research the company’s background, products or services, and industry trends.

- This demonstrates your interest and preparation.

- Use industry-specific terms and examples in your answers.

2. Highlight Your Skills and Experience

Emphasize your hands-on experience in material handling, drill press operation, and quality control.

- Quantify your accomplishments using specific numbers and metrics.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Show Your Mechanical Aptitude

Discuss your understanding of basic mechanical principles and your ability to troubleshoot equipment issues.

- Share examples of how you identified and resolved problems with tools or machinery.

- Demonstrate your willingness to learn and adapt to new technologies.

4. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation.

- Practice answering questions about your strengths and weaknesses.

- Be prepared to discuss your career goals and how they align with the company’s.

5. Dress Professionally and Be Punctual

Dress appropriately for the interview and arrive on time.

- First impressions matter, so make sure you present yourself well.

- Punctuality shows that you respect the interviewer’s time.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Drill Press Operator Helper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.