Feeling lost in a sea of interview questions? Landed that dream interview for Driller and Broacher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Driller and Broacher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

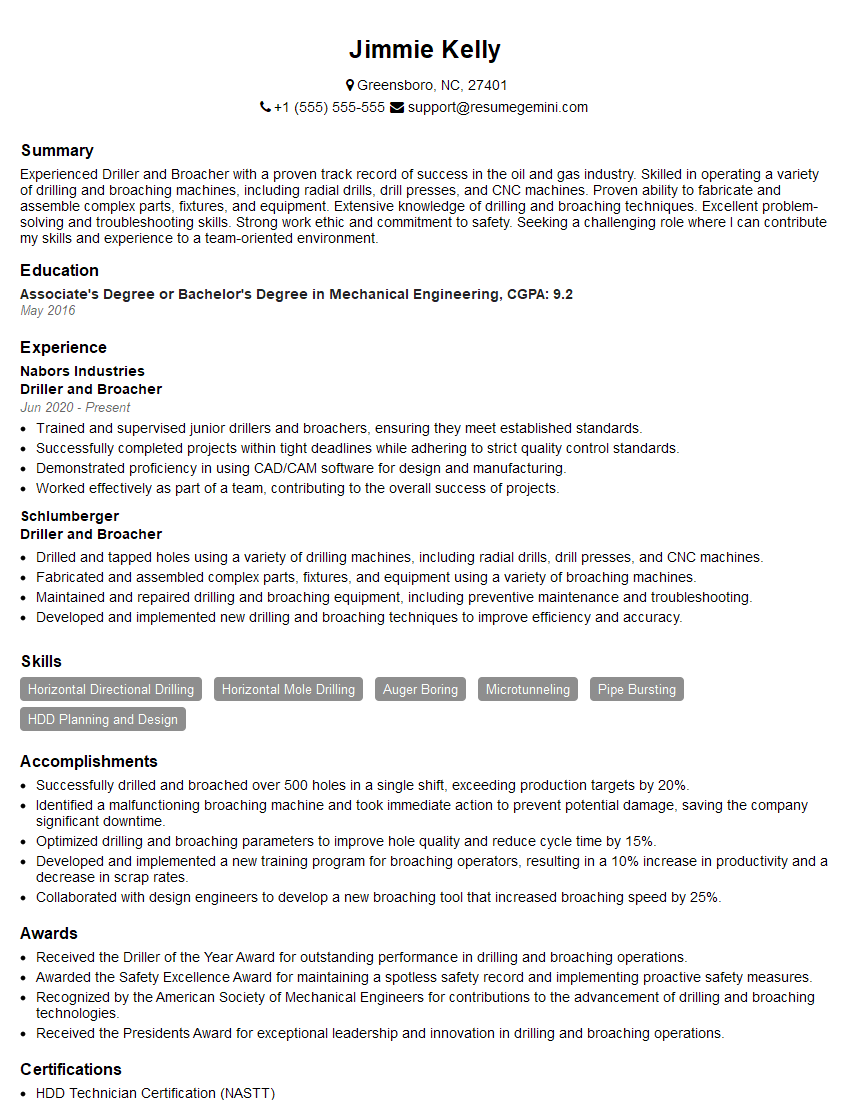

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Driller and Broacher

1. Explain the key responsibilities of a Driller and Broacher.

Answer

- Operate drilling and broaching machines to create holes, slots, and other shapes in various materials.

- Set up and adjust machines according to specifications.

- Monitor the drilling and broaching process to ensure accuracy and efficiency.

- Maintain and troubleshoot equipment to ensure optimal performance.

- Follow safety protocols and wear appropriate personal protective equipment.

2. Describe the different types of drilling and broaching machines you have operated.

Answer

- Drilling machines: Radial drills, drill presses, CNC drilling machines

- Broaching machines: Vertical broaching machines, horizontal broaching machines, surface broaching machines

3. What are the critical measurements and tolerances you need to consider when drilling and broaching?

Answer

- Hole diameter, depth, and location

- Slot width, depth, and location

- Surface finish and roughness

- Material thickness and hardness

- Tool size and sharpness

4. How do you ensure the accuracy and precision of drilled and broached holes?

Answer

- Properly calibrate and maintain drilling and broaching machines.

- Use sharp and high-quality tools.

- Follow established procedures and specifications.

- Use precision measuring instruments to verify accuracy.

- Implement quality control measures during the process.

5. What types of materials have you drilled and broached?

Answer

- Metals: Steel, aluminum, brass, copper

- Plastics: ABS, PVC, HDPE

- Composites: Fiberglass, carbon fiber

- Wood

- Other: Glass, ceramics

6. How do you handle complex drilling and broaching operations?

Answer

- Develop and follow detailed work plans.

- Use specialized tooling and fixtures.

- Coordinate with other team members and departments.

- Troubleshoot and resolve technical issues.

- Document the process and results.

7. What is your experience with programming and operating CNC drilling and broaching machines?

Answer

8. How do you stay updated on the latest drilling and broaching technologies and best practices?

Answer

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and discussion groups.

- Consult with experts and vendors.

9. What are some of the safety precautions you observe when operating drilling and broaching machines?

Answer

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and earplugs.

- Securely fasten workpieces to prevent movement.

- Keep the work area clean and free of debris.

- Follow established lockout/tagout procedures.

- Be aware of potential hazards, such as rotating tools and sharp edges.

10. How would you contribute to our team as a Driller and Broacher?

Answer

- Use my technical skills and experience to produce high-quality drilled and broached parts.

- Contribute to process improvement and optimization initiatives.

- Work effectively as part of a team to meet production goals.

- Maintain a positive and safety-conscious work attitude.

- Be a valuable asset to your organization.

11. Describe your experience with different types of cutting tools used in drilling and broaching.

Answer

- Drills: Twist drills, carbide drills, hole saws

- Broaches: Pull broaches, push broaches, surface broaches

- Cutting inserts: Carbide inserts, ceramic inserts, CBN inserts

- Tool selection: Consider factors such as material type, hole size, and surface finish.

12. Explain the different types of coolants used in drilling and broaching and their applications.

Answer

- Oil-based coolants: Provide lubrication and cooling

- Water-based coolants: Effective for high-speed applications

- Synthetic coolants: Offer a balance of lubrication and cooling

- Coolant selection: Depends on factors such as material type, cutting tool, and machining parameters.

13. How do you ensure the proper maintenance and calibration of drilling and broaching machines?

Answer

- Regularly clean and lubricate machines.

- Inspect and adjust components as per manufacturer’s recommendations.

- Calibrate machines using precision measuring tools.

- Follow established maintenance schedules.

- Keep detailed maintenance records.

14. How do you handle and store tools and materials safely?

Answer

- Use appropriate storage containers for tools and materials.

- Keep cutting tools sharp and properly stored.

- Handle materials carefully to prevent damage.

- Dispose of waste materials properly.

- Maintain a clean and organized work area.

15. Describe your understanding of quality control procedures in drilling and broaching operations.

Answer

- Inspect parts for dimensional accuracy and surface finish.

- Use measuring tools such as calipers, micrometers, and gauges.

- Follow established quality standards.

- Document inspection results and take corrective actions if necessary.

- Continuously improve quality control processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Driller and Broacher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Driller and Broacher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drillers and Broachers are responsible for operating drilling and boring machines to create holes in various materials such as metal, wood, or plastic. They work in manufacturing, construction, and other industries.

1. Drilling Operations

Drillers are responsible for the following drilling operations:

- Selecting and installing the appropriate drill bits and attachments.

- Setting up and operating drilling machines according to specifications.

- Drilling holes to precise depths and diameters.

- Inspecting and measuring drilled holes to ensure accuracy.

2. Broaching Operations

Broachers are responsible for the following broaching operations:

- Selecting and installing the appropriate broaching tools.

- Setting up and operating broaching machines according to specifications.

- Broaching holes to precise shapes and sizes.

- Inspecting and measuring broached holes to ensure accuracy.

3. Maintenance and Troubleshooting

Drillers and Broachers are also responsible for:

- Performing regular maintenance and cleaning on drilling and broaching machines.

- Troubleshooting and resolving machine issues.

- Following safety protocols and wearing appropriate safety gear.

Interview Tips

To ace the interview for a Driller and Broacher position, candidates should consider the following tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Driller and Broacher position. This will help you understand the company’s culture, values, and the responsibilities of the role. You can visit the company website, check industry news, or connect with current or former employees on LinkedIn.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to drilling and broaching operations, such as:

- Tell me about your experience with drilling and broaching machines.

- How do you ensure accuracy when drilling or broaching holes?

- What are some of the challenges you have faced in previous drilling or broaching roles?

You can use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples from your work experience.

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience during the interview. Quantify your accomplishments whenever possible to demonstrate your impact in previous roles. For example, you could mention the number of holes you have drilled or broached, the accuracy you achieved, or any cost savings you have contributed to through efficient operations.

4. Ask Thoughtful Questions

During the interview, ask thoughtful questions to show your interest in the company and the position. This is an opportunity for you to clarify details about the role, the team, or the company’s goals. It also demonstrates your enthusiasm and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Driller and Broacher interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.