Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Drilling and Production Superintendent interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Drilling and Production Superintendent so you can tailor your answers to impress potential employers.

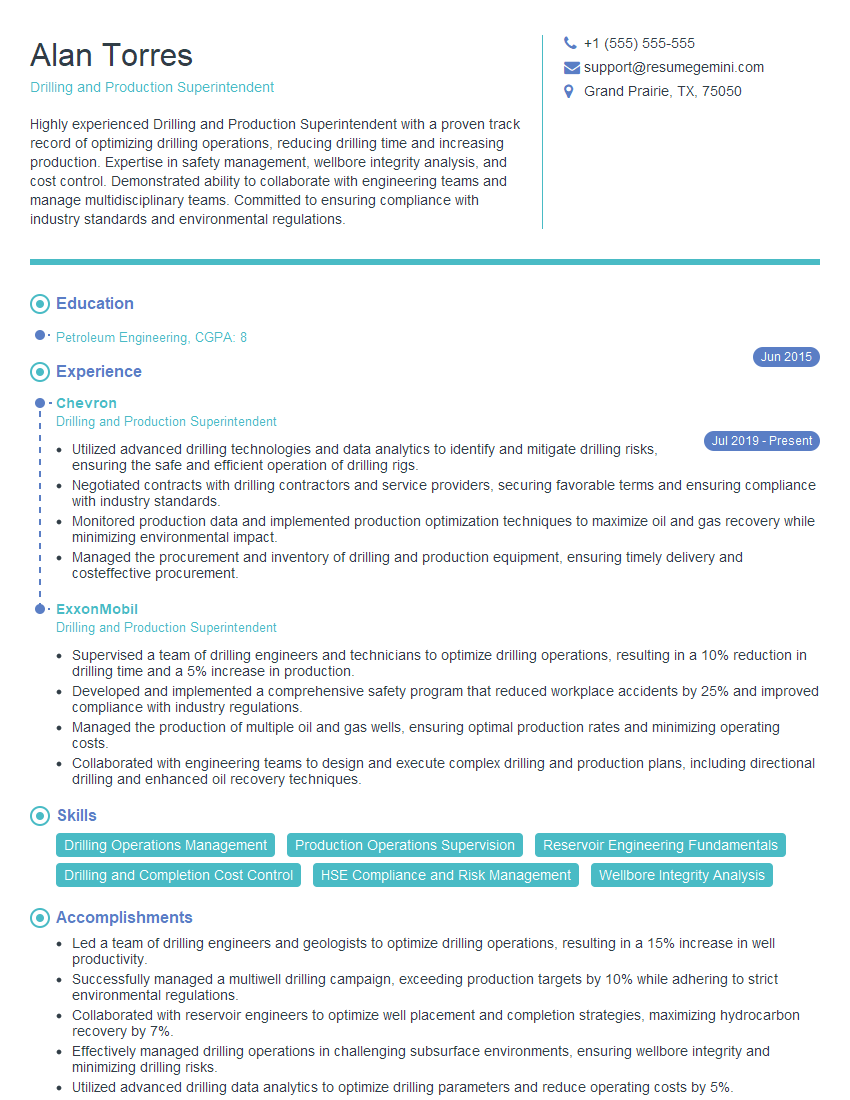

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drilling and Production Superintendent

1. What are the critical factors to consider when designing a drilling program for an offshore platform?

- Wellbore trajectory and profile determination

- Selection of drilling rig and equipment

- Formation characteristics and drilling fluids compatibility

- Environmental conditions and safety considerations

- Cost estimation and feasibility analysis

2. Describe the different types of drilling rigs, their capabilities, and their applications.

Submersible Drilling Rig

- Floats on the water surface and can move from one location to another

- Suitable for drilling in shallow to medium-depth waters

Jack-Up Drilling Rig

- Has legs that can be extended to the seabed and lifted to elevate the rig above water level

- Used for drilling in relatively shallow waters

Semi-Submersible Drilling Rig

- Supported by pontoons that allow it to float and submerse to a certain depth

- Suitable for drilling in deep water depths

Drill Ship

- A ship specifically designed for drilling

- Can drill in ultra-deep waters and in harsh environments

3. What are the key factors influencing drilling fluid selection?

- Formation characteristics and drilling parameters

- Rheological properties and cuttings carrying capacity

- Compatibility with formation fluids and contaminants

- Environmental regulations and waste management

- Cost and availability

- Health, safety, and environmental considerations

4. Explain the importance of kick detection and control in drilling operations.

- Early detection of abnormal increases in well pressure

- Prevention of well blowouts and uncontrolled release of hydrocarbons

- Safe and efficient management of drilling operations

- Compliance with regulatory requirements and environmental standards

- Protection of personnel, assets, and the environment

5. Describe the methods used for wellbore stabilization and cementing.

Wellbore Stabilization

- Drilling mud weight optimization

- Mud additives for hole stability

- Casing and liner installation

- Hole deviation control

Cementing

- Slurry design and preparation

- Casing or liner running and cementing

- Displacement and curing of cement

- Cement evaluation and testing

6. What are the best practices for optimizing drilling efficiency and reducing non-productive time (NPT)?

- Rigorous planning and coordination

- Proper equipment selection and maintenance

- Efficient rig operations and crew management

- Real-time data monitoring and analysis

- Proactive maintenance and troubleshooting

7. How do you manage production and reservoir engineering aspects of drilling and completion operations?

- Reservoir characterization and modeling

- Production forecasting and optimization

- Completion design and selection

- Well testing and evaluation

- Production data analysis and interpretation

8. What are the challenges and opportunities in deepwater drilling and production?

Challenges

- High pressure and temperature environments

- Complex geology and reservoir characteristics

- Technical and operational complexities

- Environmental risks and regulations

Opportunities

- Access to significant hydrocarbon resources

- Technological advancements and innovative solutions

- Economic benefits and job creation

- Energy security and diversification

9. Describe the role and responsibilities of a Drilling and Production Superintendent.

- Oversee drilling and production operations

- Ensure safety, efficiency, and compliance

- Manage personnel and resources effectively

- Collaborate with engineering, geology, and operations teams

- Report to senior management and stakeholders

10. How do you stay up-to-date with the latest industry trends and best practices?

- Attend industry conferences and workshops

- Read technical journals and publications

- Participate in professional organizations

- Network with colleagues and experts

- Engage in continuing education and training programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drilling and Production Superintendent.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drilling and Production Superintendent‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Drilling and Production Superintendent

1. Operational Planning and Execution: – Manage and coordinate drilling and production operations to ensure efficient execution. – Develop and implement drilling plans, optimize drilling processes, and monitor drilling performance. – Monitor and manage well production operations, including optimization, maintenance, and troubleshooting. – Collaborate with drilling contractors and other stakeholders to ensure seamless operations. 2. Equipment and Facility Management: – Supervise the maintenance and upkeep of drilling equipment, including rigs, pumps, and other machinery. – Manage the maintenance and repair of production facilities, including pipelines, separators, and storage tanks. – Implement safety protocols and ensure compliance with regulatory standards for equipment and facility operations. 3. Safety and Environmental Compliance: – Enforce safety regulations and best practices throughout drilling and production operations. – Conduct safety audits, develop and implement safety programs, and monitor compliance. – Ensure compliance with environmental regulations, including emission control, waste management, and spill prevention. 4. Human Resources Management: – Supervise and lead a team of drilling and production personnel, including engineers, technicians, and operators. – Train and develop staff, ensuring they have the necessary skills and knowledge to perform their roles effectively. – Evaluate performance, provide feedback, and support professional development. 5. Budget and Cost Control: – Manage operational budgets and control expenses related to drilling and production activities. – Optimize costs by implementing efficient practices, negotiating contracts, and managing resources effectively. – Monitor and report on financial performance to management.Interview Preparation Tips for the Drilling and Production Superintendent Role

1. Research the Company and Industry: – Thoroughly research the company and its drilling and production operations. – Stay updated on industry trends and best practices in drilling and production. 2. Practice Common Interview Questions: – Prepare answers to common interview questions related to your experience, skills, and qualifications. – Consider the STAR method (Situation, Task, Action, Result) to structure your responses and highlight your accomplishments. 3. Demonstrate Technical Knowledge: – Showcase your understanding of drilling and production principles, equipment, and processes. – Be prepared to discuss your experience in drilling operations, well management, and facility operations. 4. Highlight Safety Expertise: – Emphasize your commitment to safety and compliance in the drilling and production industry. – Share examples of your experience in implementing safety protocols and managing risk. 5. Quantify Accomplishments: – Use specific data and metrics to quantify your accomplishments in drilling and production operations. – Highlight the impact of your contributions, such as improved production rates, reduced costs, or enhanced safety performance. 6. Be Prepared for Case Studies: – You may be asked to discuss specific case studies related to drilling or production operations. – Be prepared to analyze the situation, identify potential solutions, and explain your recommendations. 7. Practice Active Listening: – Pay attention to the interviewer’s questions and respond thoughtfully. – Ask clarifying questions to ensure you understand their expectations. 8. Follow Up: – After the interview, send a thank-you note to the interviewer, reiterating your interest in the position.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drilling and Production Superintendent interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.